Automatic impressing paper collection type card printing machine

A printing machine and card technology, which is applied in stacking receiving devices, sending objects, thin material processing, etc., can solve the problems of low pass rate, poor finishing effect, frequent problems, etc., to improve stacking and sorting, improve sorting effect, The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

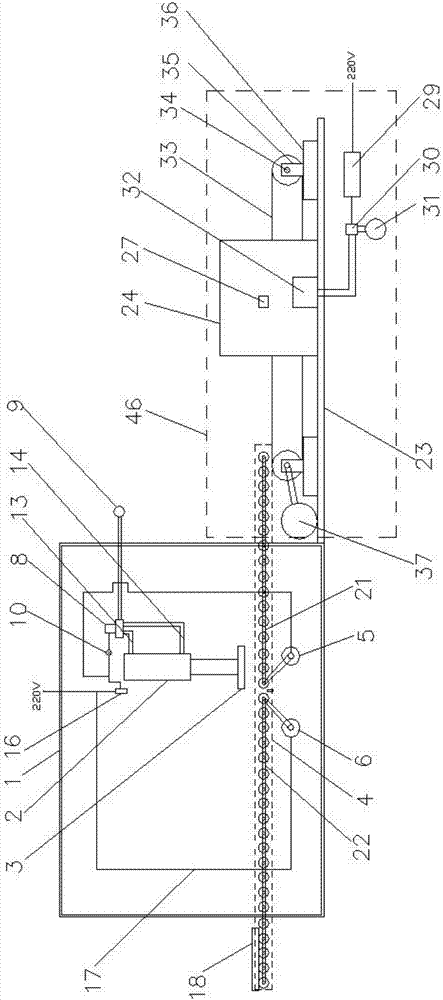

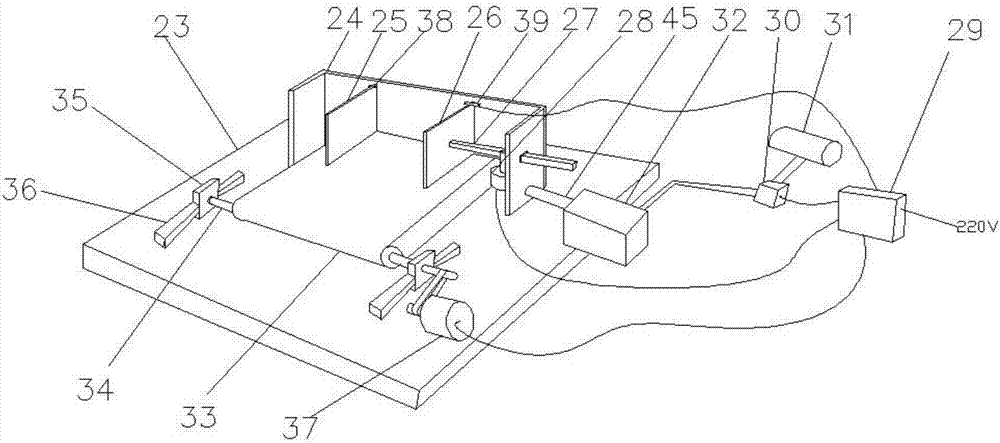

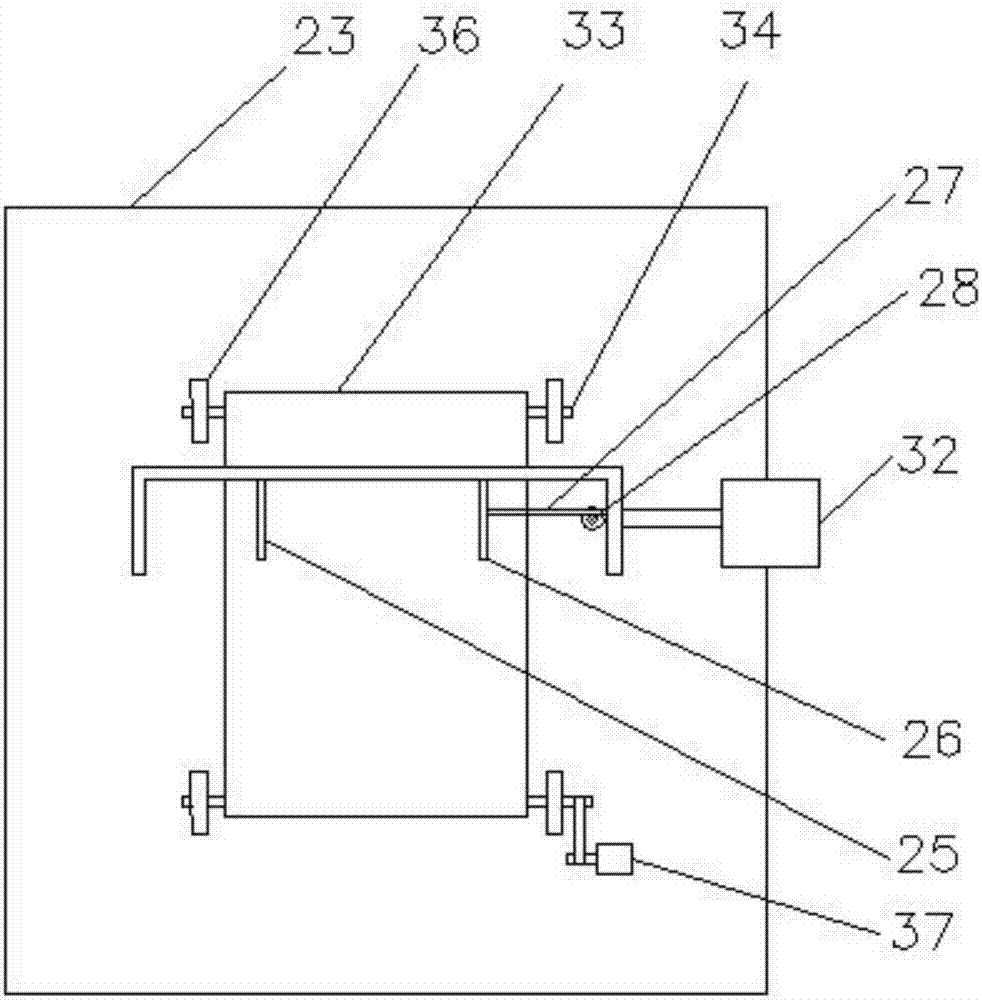

[0025] Example. An automatic embossing and receiving type card printing machine, which is composed of Figures 1 to 8 As shown, including a frame 1, a No. 1 cylinder 2 is arranged in the frame 1, a printing plate 3 is fixedly connected to the bottom of the No. 1 cylinder 2, and a transfer roller 4 is arranged below the printing plate 3; one side of the No. 1 cylinder 2 is connected to an electromagnetic Valve 8; one end of the electromagnetic valve 8 is connected with an air pump 9, and the other end is connected with a delay switch 10, and the delay switch 10 is connected with a through-beam photoelectric switch 7, and the through-beam photoelectric switch 7 is arranged on one side of the printing plate 3; One side of the frame 1 is provided with a paper feeding mechanism 46, the paper feeding mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com