Novel bag-type MBR flat-sheet membrane module

A flat membrane, bag type technology, applied in the field of MBR membrane group, can solve the problems of high cost and unfavorable promotion, and achieve the effect of good support, improved filtration effect, and easy cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

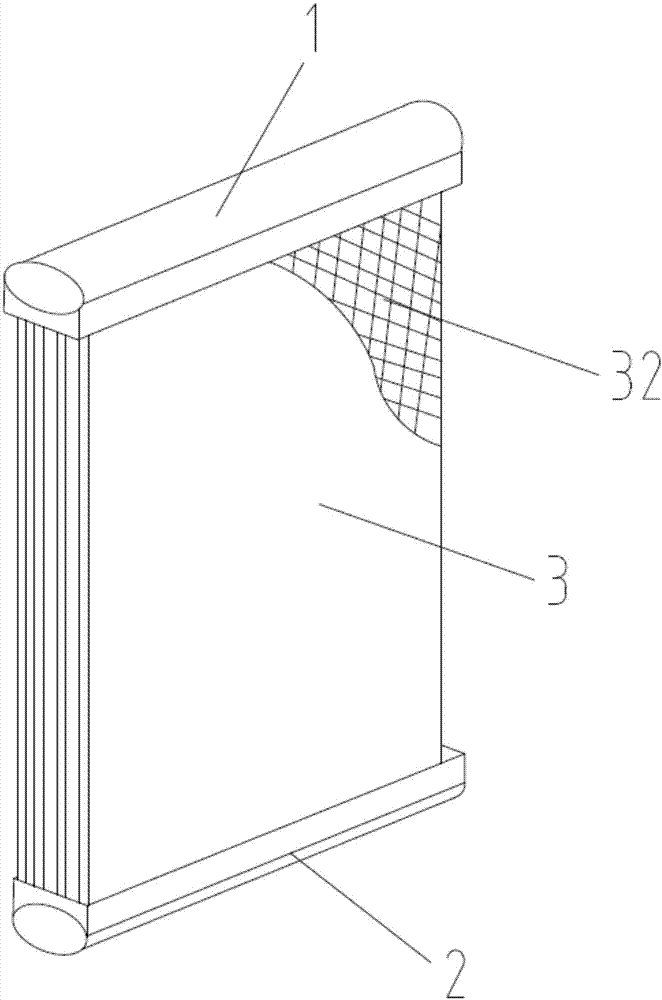

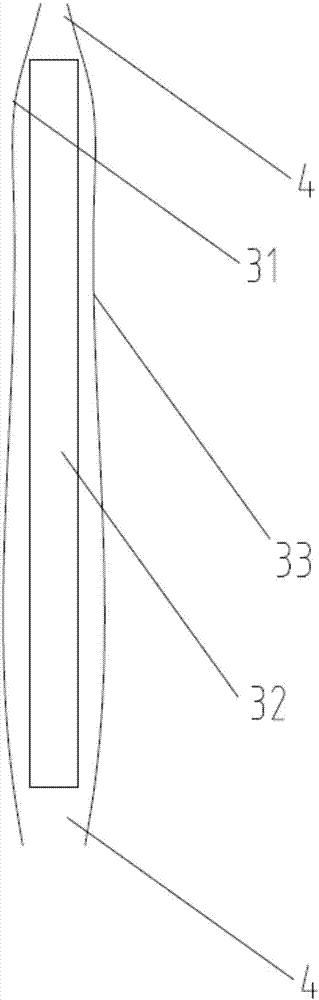

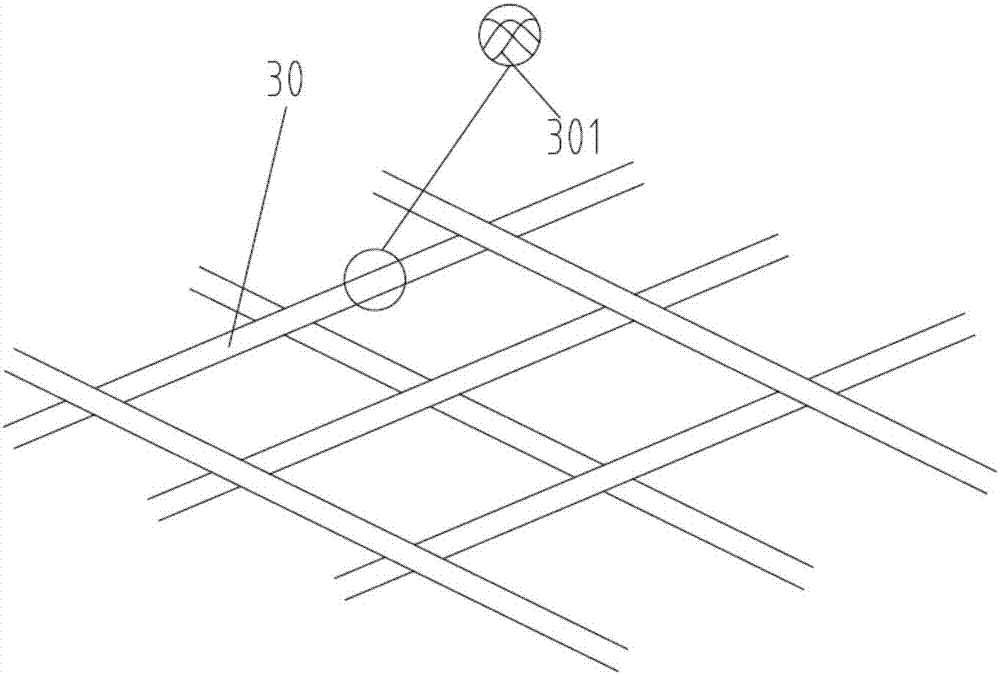

[0026] As shown in the figure, a novel bag-type MBR flat membrane group includes an upper bracket 1, a lower bracket 2, and a number of flat membrane groups 3, and the flat membrane group 3 includes a flat membrane one 31, a flat guide net 32 and a flat membrane Two 33, the flat film one 31 and the flat film two 33 are connected and the flat guide net 32 is packaged inside the flat film one 31 and the flat film two 33, and the flat film one 31 and the flat film two 33 are upper and lower two An opening 4 is provided at the end, an upper bracket 1 is installed above the flat membrane group 3, and a lower bracket 2 is installed below the flat membrane group 3; both the upper bracket 1 and the lower bracket 2 include The connecting port 11 and the hollow tube 12 for the filtered water to flow out; the upper bracket 1 is installed above the flat membrane group 3 means that the opening 4 of the flat membrane group 3 is installed on the upper bracket 1 by bonding mouth 11; the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com