Universal life-clothing waste-textile regenerated spinnable fiber production technology

A production process and textile technology, which is applied in the field of production process of regenerated spinnable fibers from waste textiles for general life clothing, can solve the problems of backward processing equipment, poor processing links, backward processing technology, etc., and achieve large-scale effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the present invention. But those skilled in the art should know that the following examples are not the sole limitation to the technical solution of the present invention, and any equivalent transformation or modification made under the spirit of the technical solution of the present invention should be considered as belonging to the protection of the present invention scope.

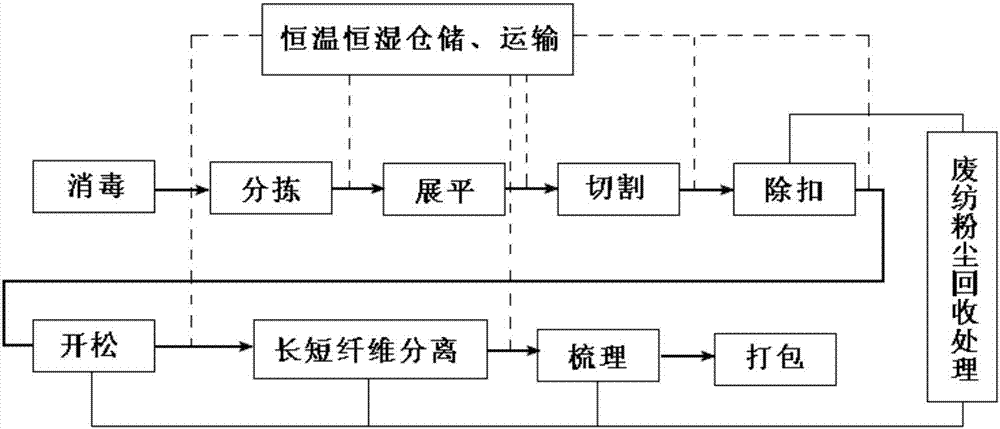

[0071] Different from industrial waste textiles, waste textiles for daily life are complex in origin, with ever-changing materials, colors, fabric textures, etc., and do not have the same properties, so it is difficult to regenerate them with simple processes. Therefore, the present invention provides a production process of regener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com