Drum coal mining device

A coal mining device and drum-type technology, applied in the direction of driving devices, earth drilling, cutting machinery, etc., can solve the problems of long mining time in thin coal seams, difficult thin coal seams, low output, etc., to achieve wide practicability, fuselage The effect of low height and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to directions in the drawings. The terms "inner" and "outer" are used to refer to directions toward or away from, respectively, the geometric center of a particular component.

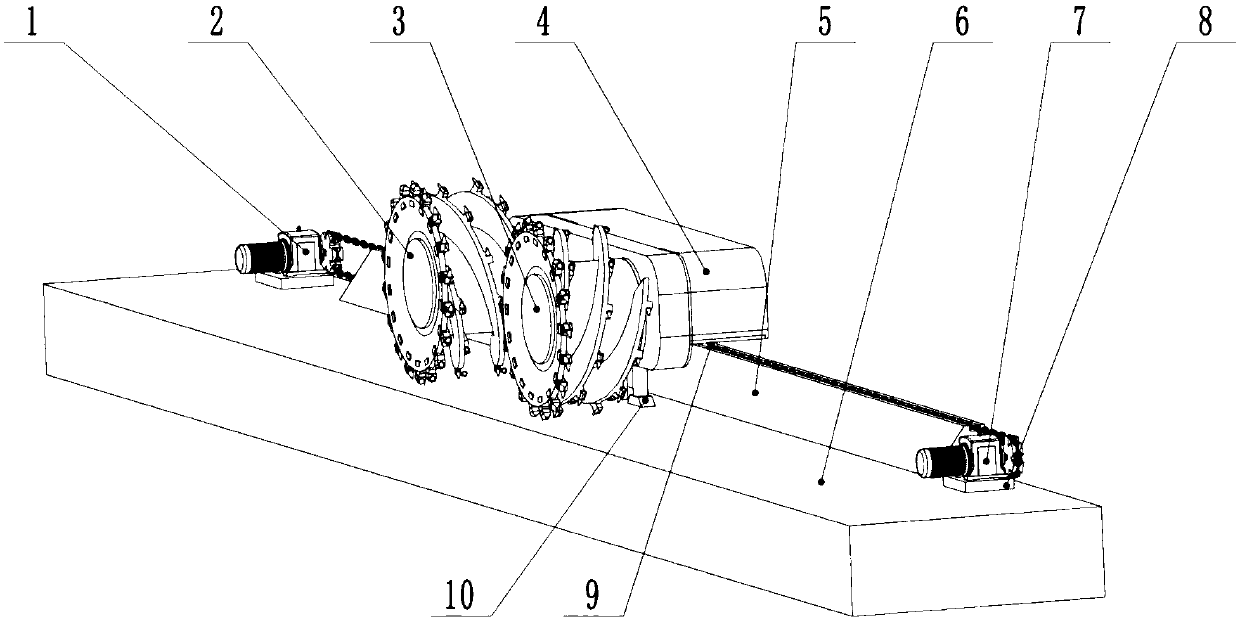

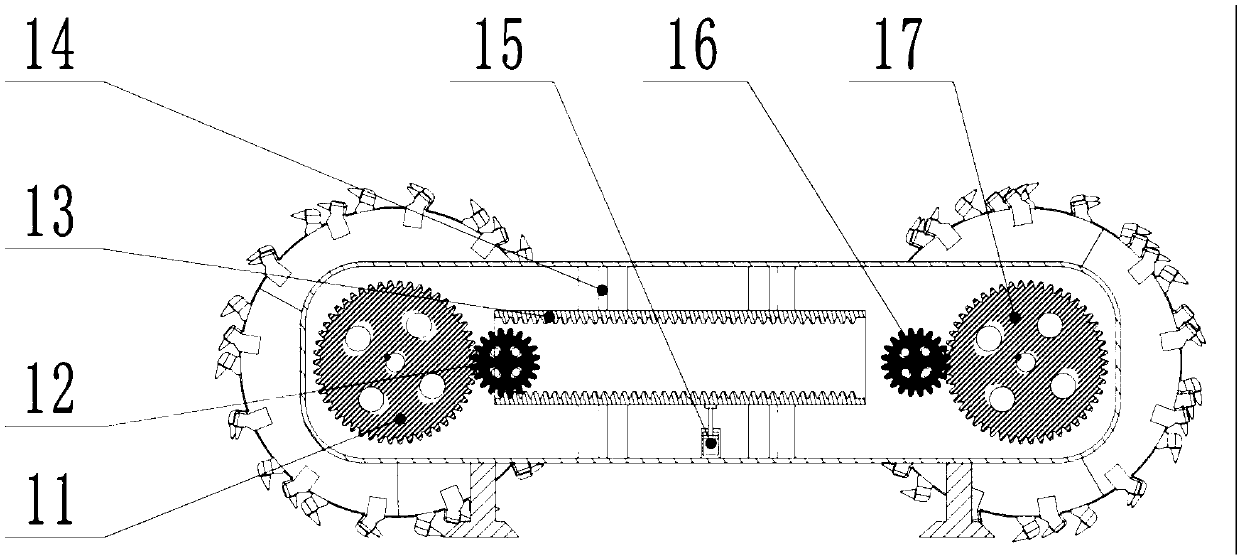

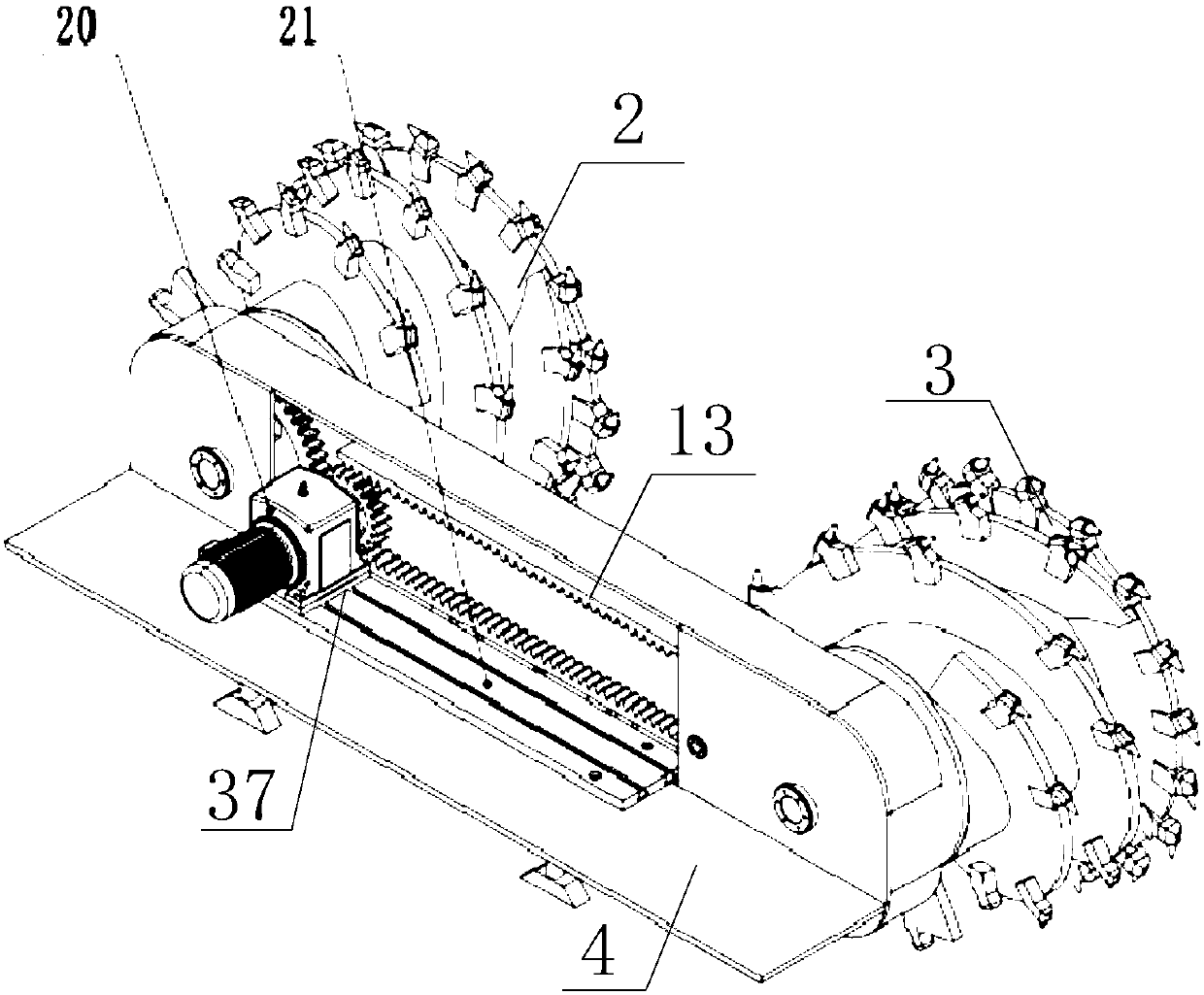

[0042] figure 1 It is a schematic diagram of the drum coal mining device adopted in the specific embodiment of the present invention. figure 2 for figure 1 A schematic diagram of the reversing mechanism of the drum coal mining device shown. image 3 for figure 1 The schematic diagram of the use state of the cutting drive mechanism of the drum coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com