Floating sealing type rotary compensator

A technology of rotary compensator and floating seal, which is applied to expansion compensating devices for pipelines, pipes/pipe joints/fittings, mechanical equipment, etc. The effect of lowering, increasing pressure, and increasing resistance to fluid erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

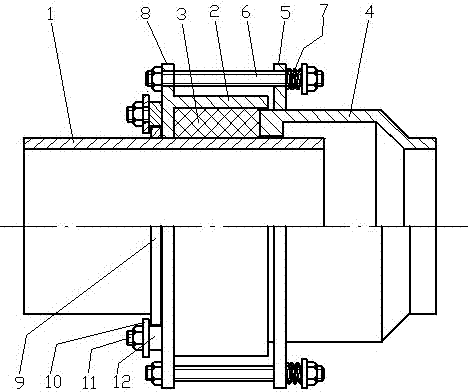

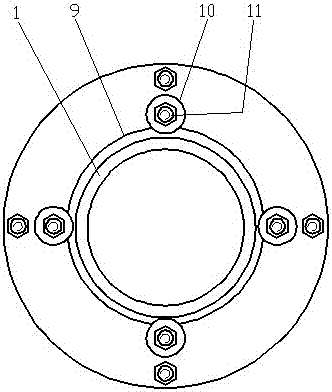

[0009] The specific embodiment of the present invention will now be described in conjunction with the accompanying drawings.

[0010] A floating seal type rotary compensator, which includes an inner cylinder 1 and a sleeve 2, the inner cylinder 1 extends on the sleeve 2, and a sealing packing 3 is arranged between the inner cylinder and the sleeve, the sealing packing is made of graphite material, and the sleeve The end surface of the inner flange at the left end is in contact with the left side of the sealing packing, the inner diameter of the inner flange matches the outer diameter of the inner cylinder, and the outer cylinder 4 is set on the right part of the inner cylinder, and the left end of the outer cylinder extends over the sleeve In the middle, the left end surface of the outer cylinder is in contact with the right side surface of the sealing packing, an outer flange 8 extends from the left end of the sleeve, a flange 5 is welded on the outer circle of the outer cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com