Method for evaluating maximum combustible gas concentration of oxidation reactor

An oxidation reactor and reactor technology, which is applied in the direction of material explosion, can solve the problems such as the inability to effectively detect the explosion danger of the oxidation reactor, and achieve the effect of good technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

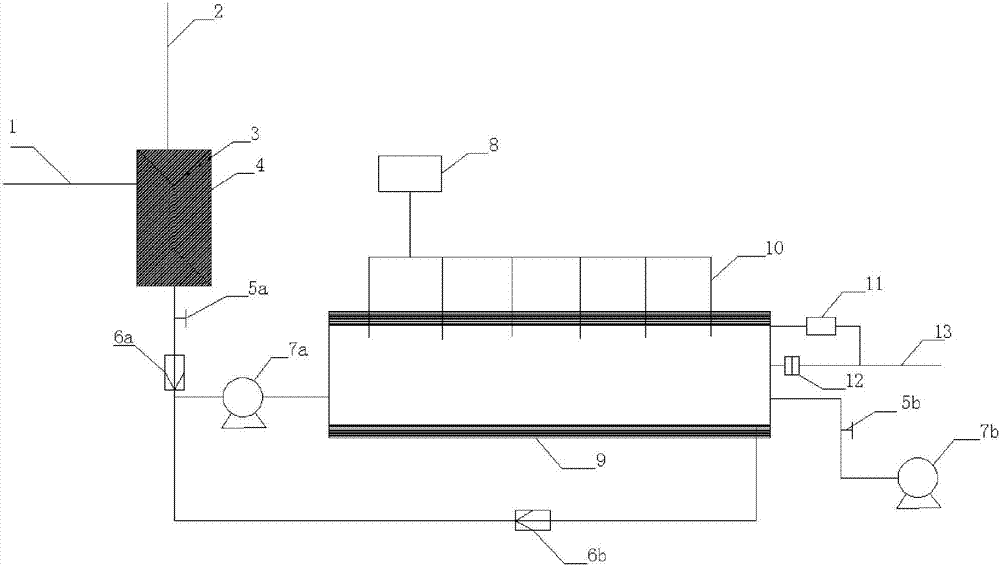

[0018] An evaluation method for the highest combustible gas concentration in an oxidation reactor, the evaluation of the highest combustible gas concentration is carried out on the oxidation reactor evaluation device, such as figure 1 As shown, the oxidation reactor evaluation device includes an oxygen mixer, a temperature-controlled reactor and a vacuum pump. The oxygen pipeline and the combustible gas pipeline are respectively connected to the oxygen mixer. It is a porous spherical non-metallic organic material. The outlet of the oxygen mixer is divided into two paths, the first path is connected to the inlet of the metering pump, the second path is connected to the outlet of the reactor with temperature control, the outlet of the metering pump is connected to the inlet of the reactor with temperature control, and the reactor with temperature control There are safety valves, burst discs and thermocouples on the top, the thermocouples are connected to the computer, and the va...

Embodiment 2

[0032] According to the conditions and steps described in Example 1, only there are 2 thermocouples in total, and the fire-retardant and explosion-proof filler is polyurethane foam sponge, which can effectively detect the explosion hazard of the oxidation reactor and provide design data.

Embodiment 3

[0034] According to the conditions and steps described in Example 1, except that there are 8 thermocouples in total, and the fire-retardant and explosion-proof filler is polyether-type porous balls, which can effectively detect the explosion hazard of the oxidation reactor and provide design data.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap