Assembly type building design method and device

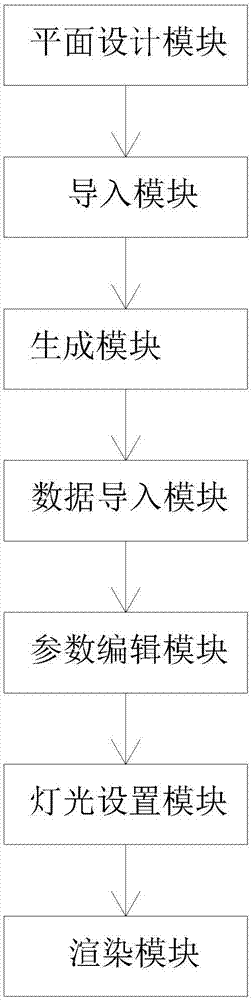

An architectural design and prefabricated technology, applied in computing, 3D modeling, image data processing, etc., can solve problems such as mistakes and intuition, and achieve the effect of not easy to make mistakes and good visual effects of graphics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0031] A kind of prefabricated building design method is characterized in that, comprises the steps:

[0032] Provide a plane line drawing of the building. The plane line drawing has the proportions of each room and wall size. Split each pattern in the plan line drawing, and interrupt the plan line drawing at the positions where doors, windows, and air outlets need to be set in each pattern lines in

[0033] In the plane line drawing, mark the places where lamps and water appliances (such as washbasins, toilets, etc.) need to be assembled, and according to the marks, make the water and electricity assembly wiring diagram in the plane line drawing;

[0034] In the planar line drawing, add the physical line assembly drawing, add the physical line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com