220kv Anti-icing and Anti-thunder composite insulator

A composite insulator, anti-icing technology, applied in insulators, suspension/strain insulators, electrical components, etc., can solve the problems of not considering the degree of icing, optimized design, small shed gap, etc., to achieve good flow performance and reasonable structure. , the effect of easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

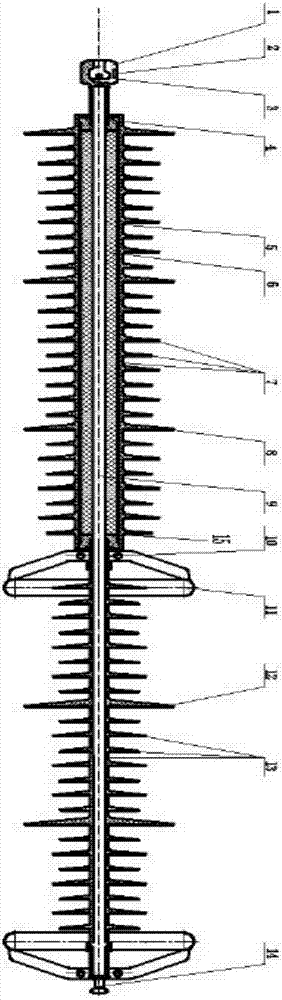

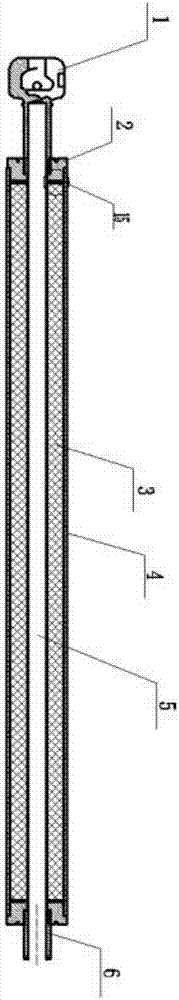

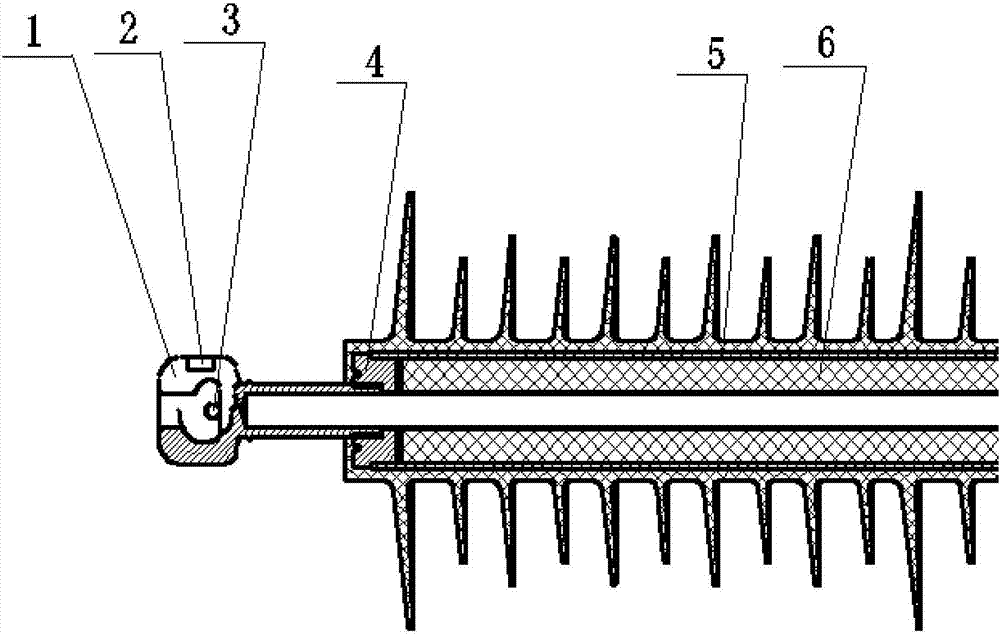

[0015] figure 1 , figure 2 , image 3 , Figure 4 It is a schematic diagram of the present invention; as shown in the figure: a 220kV ice and lightning protection composite insulator, characterized in that it includes a ball socket (1), a nameplate (2), a 20R type locking pin (3), and an electrode (4) , winding tube (5), zinc oxide resistor (6), upper umbrella (8), shed shed one (7), mandrel (9), connecting sleeve (10), equalizing ring (11), lower end The large umbrella (12), the second umbrella skirt cover (13), the ball head (14), the wave spring washer (15), the nameplate (2) is pasted on the ball socket (1), and the 20R type locking pin (3) is installed on the The inside of the ball socket (1) is used to lock the ball socket (1) and one end of the mandrel (9); the ball head (14) is installed on the other end of the mandrel (9), and the wave spring washer (15) Tightly installed on both ends of the zinc oxide resistance sheet (6); the upper end of the electrode (4) is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com