Manufacturing method of trench isolation structure

A manufacturing method and trench isolation technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as poor uniformity of trench isolation structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to have a clearer understanding of the technical features, purposes and beneficial effects of the present invention, the technical solutions of the present invention are described in detail below in conjunction with the following specific embodiments and accompanying drawings. However, it can be easily understood that the embodiments of the present invention provide many suitable The inventive concepts may be implemented in a wide variety of specific contexts. The specific embodiments disclosed are only used to illustrate how to make and use the invention in a specific way, and are not intended to limit the scope of the invention. Furthermore, the same reference numerals are used in the drawings and descriptions of the embodiments of the present invention to denote the same or similar components.

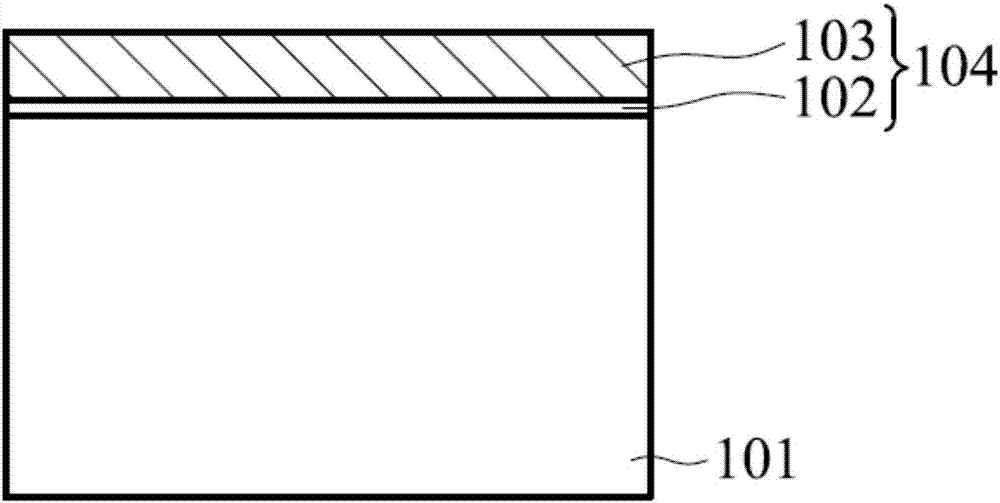

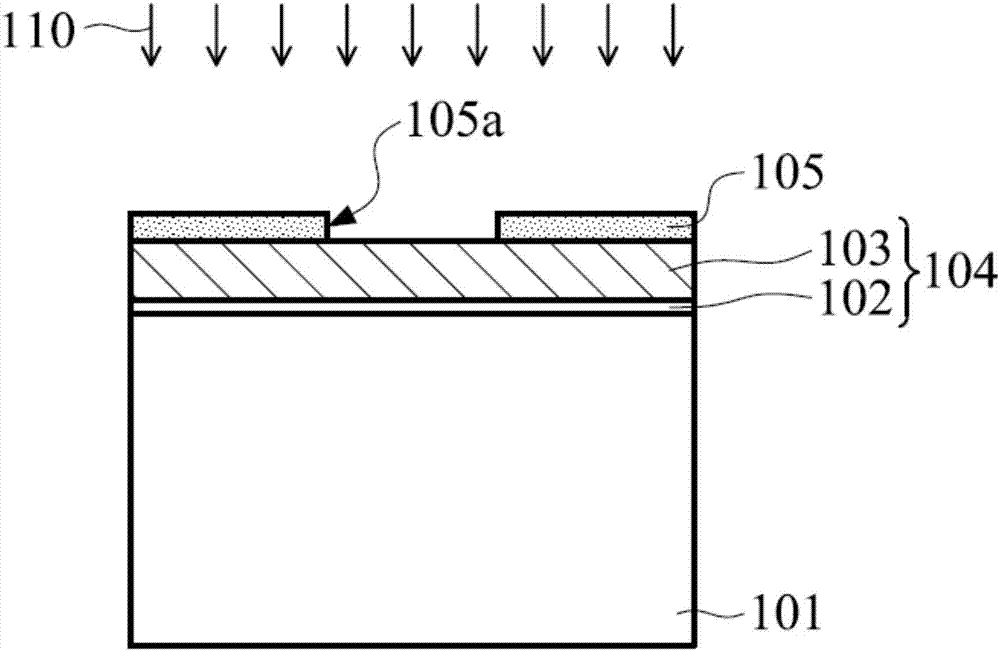

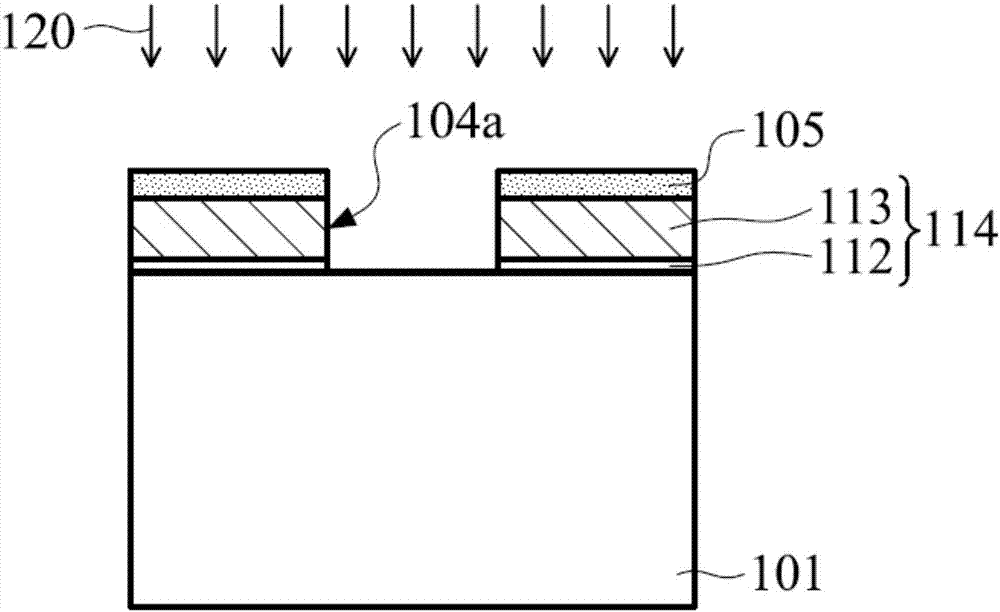

[0058] Please refer to Figures 1A-1K , which shows schematic cross-sectional views at various stages of the manufacturing method for forming the trench isolation st...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap