Material basket type automatic feeding and discharging machine tool positioned outside machine

A technology of automatic loading and unloading and external positioning. It is applied in positioning devices, metal processing machinery parts, clamping and other directions. It can solve the problem of affecting the positioning accuracy of the workpiece and the service life of the positioning fixture, adverse processing area observation, operation and maintenance, positioning fixtures. Damage and other problems, to achieve the effect of improving service life and accuracy retention, simple structure, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

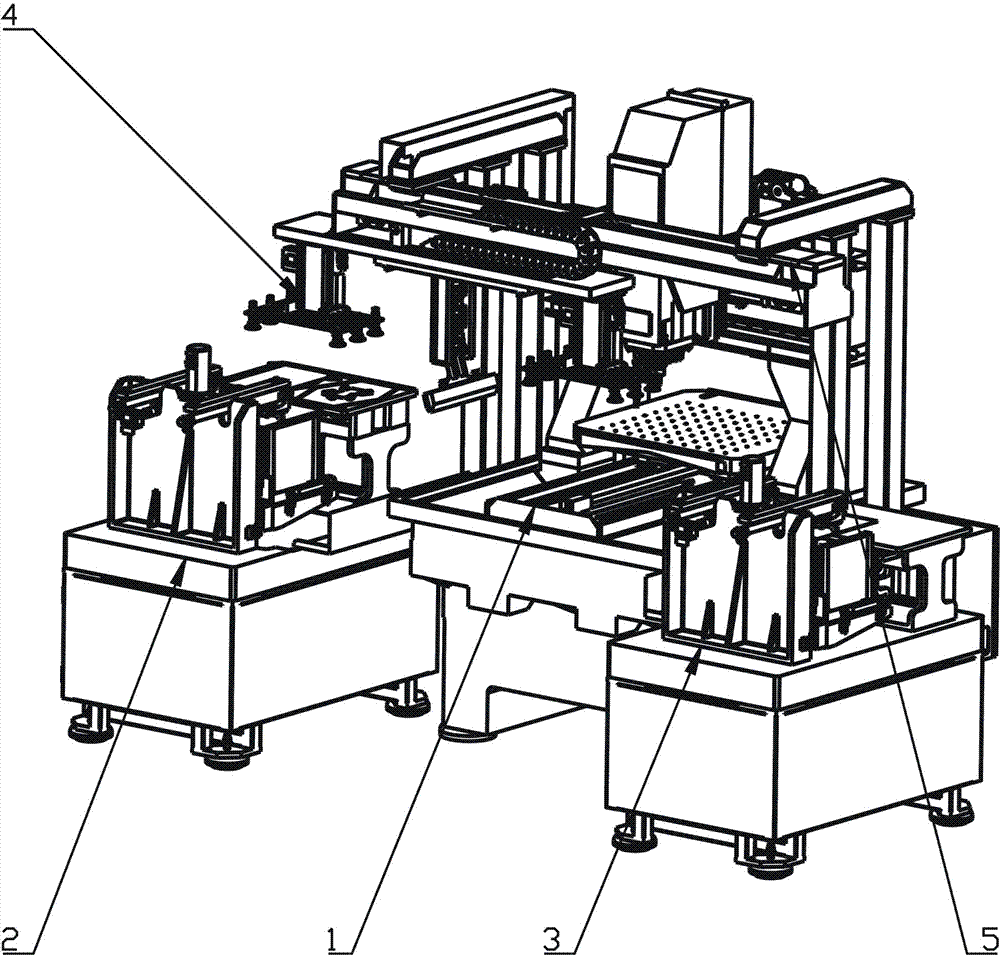

[0015] Such as figure 1 As shown, a basket-type automatic loading and unloading machine tool positioned outside the machine of the present invention is composed of a processing area 1, a loading area 2, an unloading area 3 and a handling manipulator 4, and the loading area 2 and the unloading area 3 are respectively Located on the left and right sides of the processing area 1, the handling manipulator 4 is set above the loading area 2, processing area 1 and unloading area 3 through the truss 5, and can move left and right between the loading area 2 and the unloading area 3 along the truss 5 .

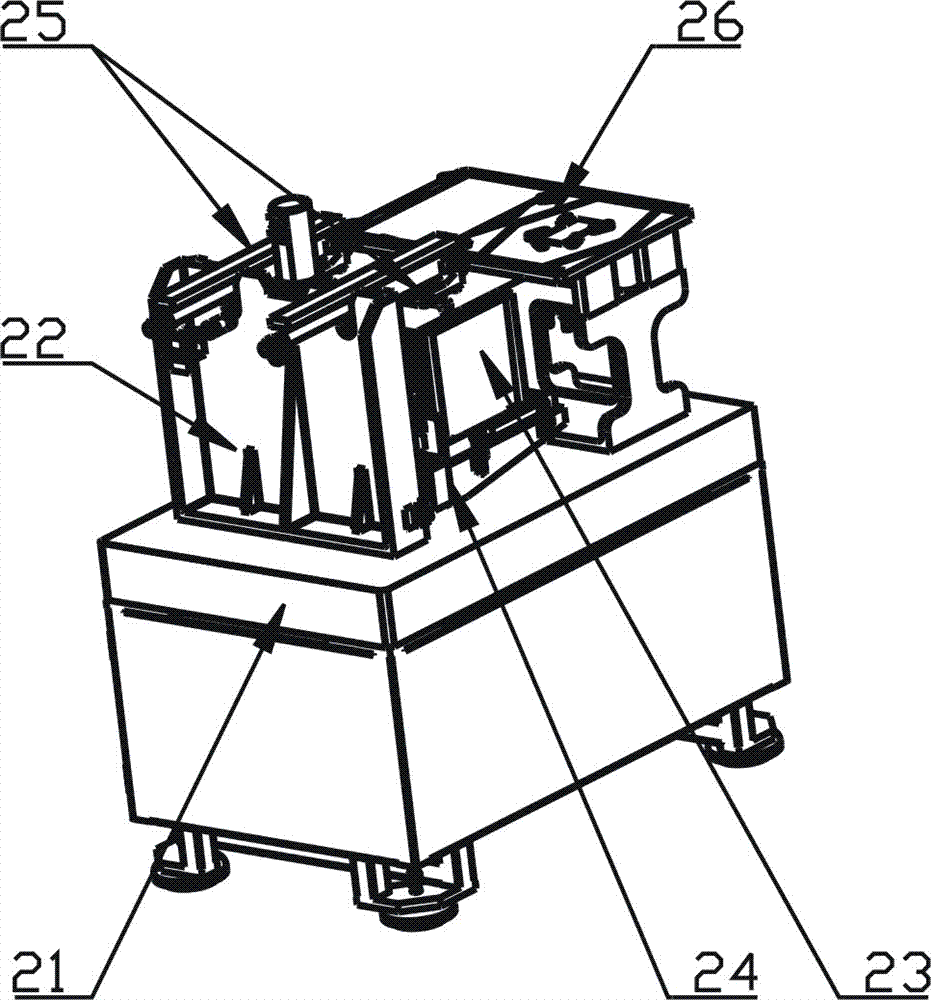

[0016] Such as figure 2 As shown, the loading area 2 is composed of a loading base 21, a loading support seat 22, a loading basket 23, a loading basket lifting mechanism 24, a loading handling device 25 and an automatic positioning device 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com