Grinding device of blade damper platform

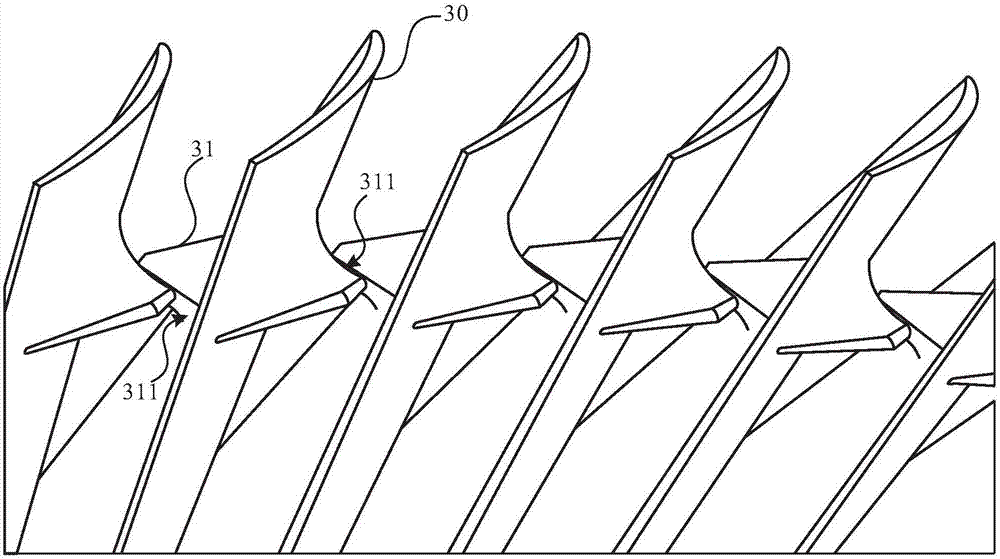

A technology of damping table and blade, which is applied in the directions of grinding drive device, grinding workpiece support, grinding machine parts, etc. 30 The problem of high local stress, to achieve the effect of simple structure, realization of positioning, and improvement of feed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

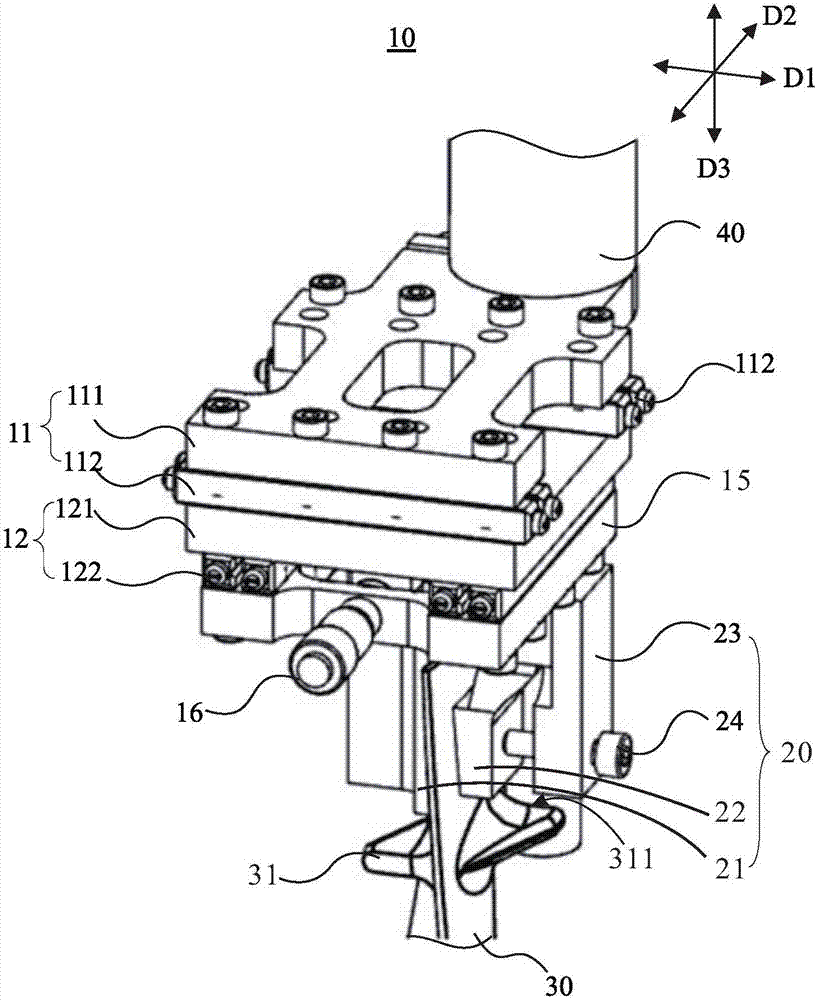

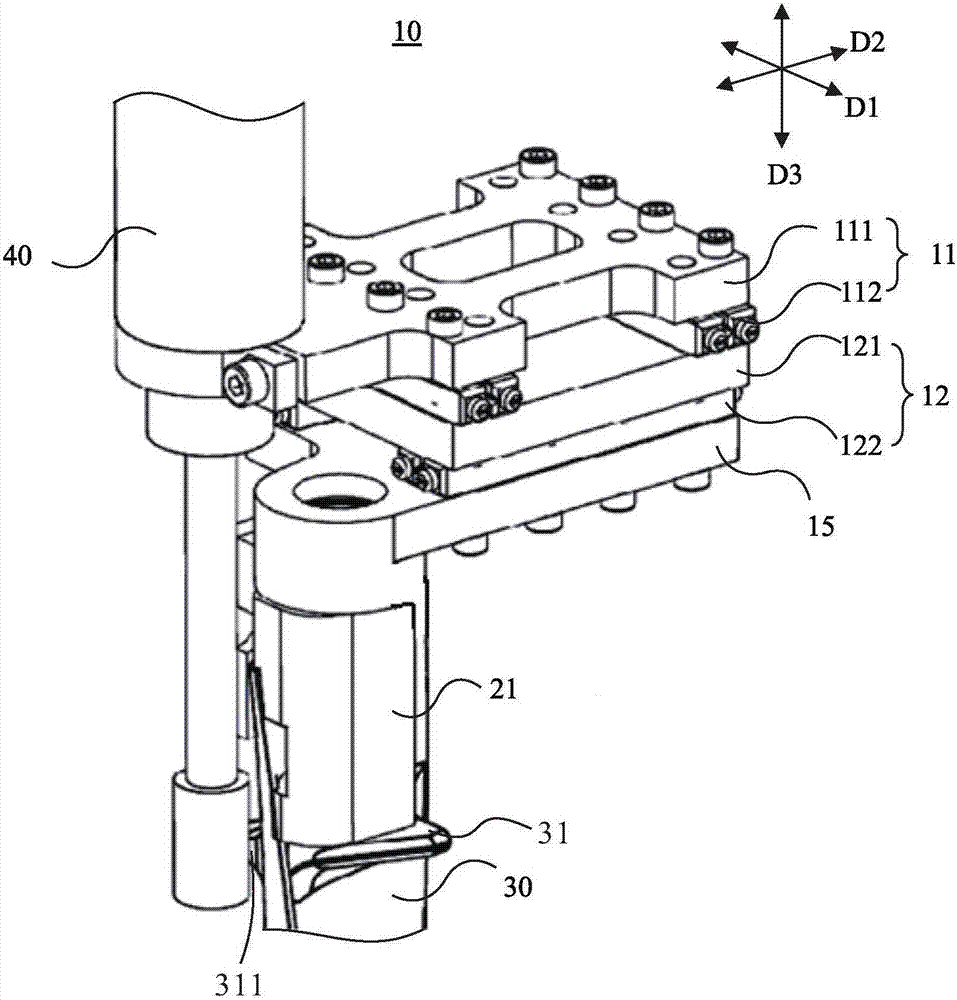

[0043] In order to make the object, technical solution and advantages of the present invention clearer, the specific implementation manner of the present utility model will be described with reference to the accompanying drawings, and the same reference numerals in each figure represent the same parts.

[0044] In order to solve the technical problem of low machining accuracy of the blade damping table in the prior art, an embodiment of the present invention provides a grinding device for the blade damping table to precisely control the processing size of the blade damping table and ensure the machining accuracy.

[0045] In order to achieve this purpose, the grinding device 10 of the blade damping table 31 provided by the embodiment of the present invention, its structure is referred to figure 2 and image 3 . Among them, it should be noted that, for the convenience of description, figure 2 and image 3 The first direction D1, the second direction D2 and the third direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com