Gastrointestinal endoscopy pathological sampling filter paper cutting device

A filter paper and pathology technology, applied in the field of medical devices, can solve the problems of cumbersome, time-consuming and laborious filter paper cutting work, and achieve the effect of saving the time of finding filter paper, reducing the difficulty of operation, and saving the amount of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

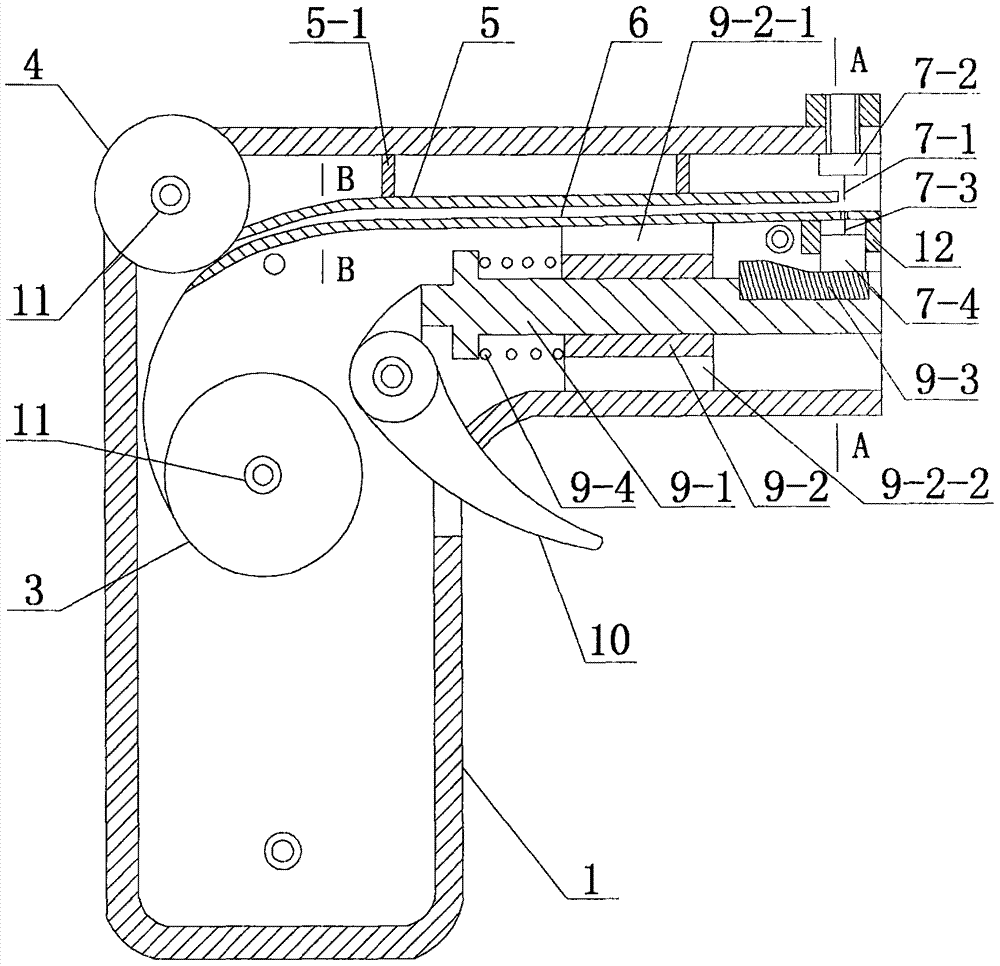

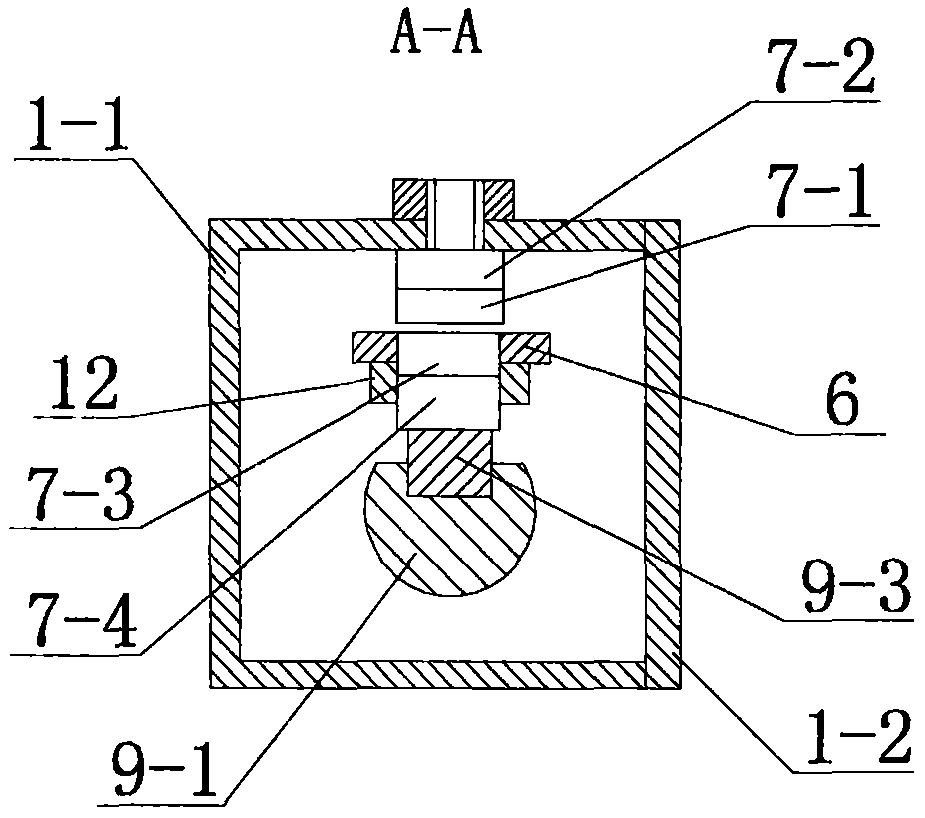

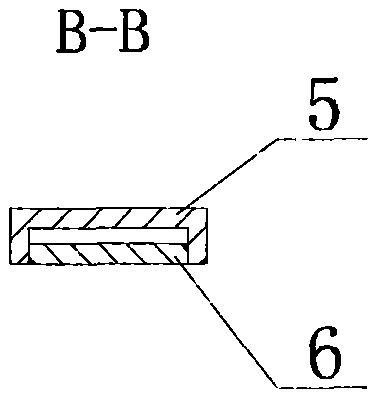

[0024] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 6 , Figure 10 , Figure 11 and Figure 12 Describe this embodiment, this embodiment comprises shell 1, filter paper reel 3, paper feed wheel 4, upper paper guide plate 5, lower paper guide plate 6, cutter assembly, push knife mechanism and paper cutting switch 10, the shell 1 The shape is L-shaped upside down, the horizontal end in the housing 1 is the filter paper outlet, the filter paper reel 3, the upper paper guide plate 5, the lower paper guide plate 6, the cutter assembly and the push knife mechanism are all arranged in the housing 1, The paper feeding wheel 4 and the upper paper guide plate 5 are sequentially arranged above the lower paper guide plate 6, the paper feed wheel 4 rolls on the lower paper guide plate 6, and the casing 1 is processed with a force application port, and the force application port Set towards the paper feed wheel 4, the upper paper guide plate 5 an...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination Figure 6 , Figure 7 , Figure 8 and Figure 9 To illustrate this embodiment, the paper cutting switch 10 in this actual mode includes a paper cutting wheel 10-1, a hand lever 10-2 and a jacking block 10-3, and the paper cutting wheel 10-1 is hinged on the shell 1 Inside, the jacking block 10-3 is fixedly connected to the paper cutting wheel 10-1, the hand lever 10-2 is installed on the shell 1, and the hand lever 10-2 is fixed at one end of the shell 1. Connect on the paper cutting wheel 10-1.

[0029] In this embodiment, the hand dial lever 10 - 2 is the hand dial part in the paper cutting switch 10 . The included angle between the jacking block 10-3 and the hand lever 10-2 is less than or equal to 90°, and the shape of the hand lever 10-2 is the same as that of the trigger in the pistol, which is an arc rod body. It is convenient for medical staff to pull and move, which is conducive to simplifying the difficulty of...

specific Embodiment approach 3

[0030] Specific implementation mode three: combination figure 1 , figure 2 , image 3 , Figure 7 and Figure 8 Describe this embodiment. In this embodiment, the knife pushing mechanism includes a slide bar 9-1, a slide bar cover 9-2, a magnet block 9-3 and a compression spring 9-4. The slide bar 9-1 is set in the slide bar cover 9-2 and slidingly fit with the sliding rod sleeve 9-2, the sliding rod 9-1 is fixedly installed in the shell 1 through the sliding rod sleeve 9-2, and one end of the sliding rod 9-1 is connected with the jacking block 10 -3 is close to each other and this end is processed with a limit protrusion. The compression spring 9-4 is set on the slide bar 9-1 and is located between the limit protrusion and the slide bar sleeve 9-2. The slide bar 9 The other end of -1 is provided with a magnet block 9-3, the upper end surface of the magnet block 9-3 is processed into a stepped surface, the high part of the stepped surface is set away from the filter paper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com