Wire cutting device

A wire and wire-carrying technology, which is applied in the field of wire cutting devices, can solve problems such as uneven wire cuts, difficulty in controlling hand force, and affecting life and work, so as to prevent electric shocks, and scientific and reasonable structure and material settings. Ensure the effect of timely maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

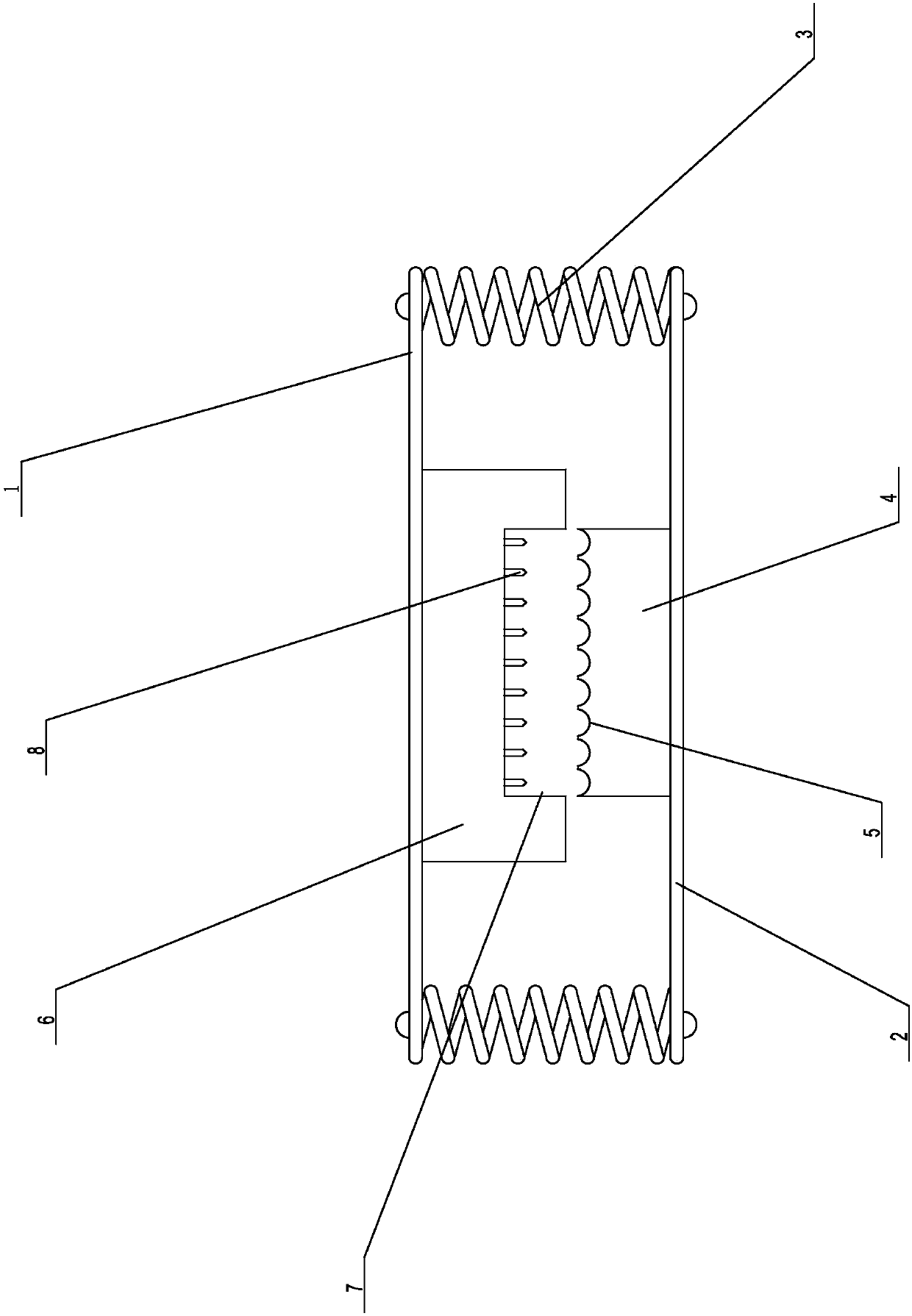

[0015] Such as figure 1 A specific embodiment of the present invention is proposed as shown, the wire cutting device includes an upper support plate 1 and a lower support plate 2 arranged transversely and parallel to each other. In order to increase the contact area, it is beneficial to stabilize and increase the force. This embodiment sets The upper support plate 1 and the lower support plate 2 are both arranged in a flat plate shape, and several springs 3 are arranged between the upper support plate 1 and the lower support plate 2. In order to ensure good elasticity and facilitate stepping and compression, this embodiment 4 springs are set, and the two ends of the 4 springs are respectively connected with the upper support plate 1 and the lower support plate 2 by screws. Under normal circumstances, the 4 springs are all in a state of natural length; the center of the top of the lower support plate 2 is A square-shaped carrier board 4 is vertically provided, and the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com