Digital hydraulic draught fan transmission system

A transmission system, digital technology, applied in the direction of transmission, wind turbine, machine/engine, etc., can solve the problems of high cost, many variable components, complex system control and optimization, etc., to achieve the effect of improving efficiency and reducing system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

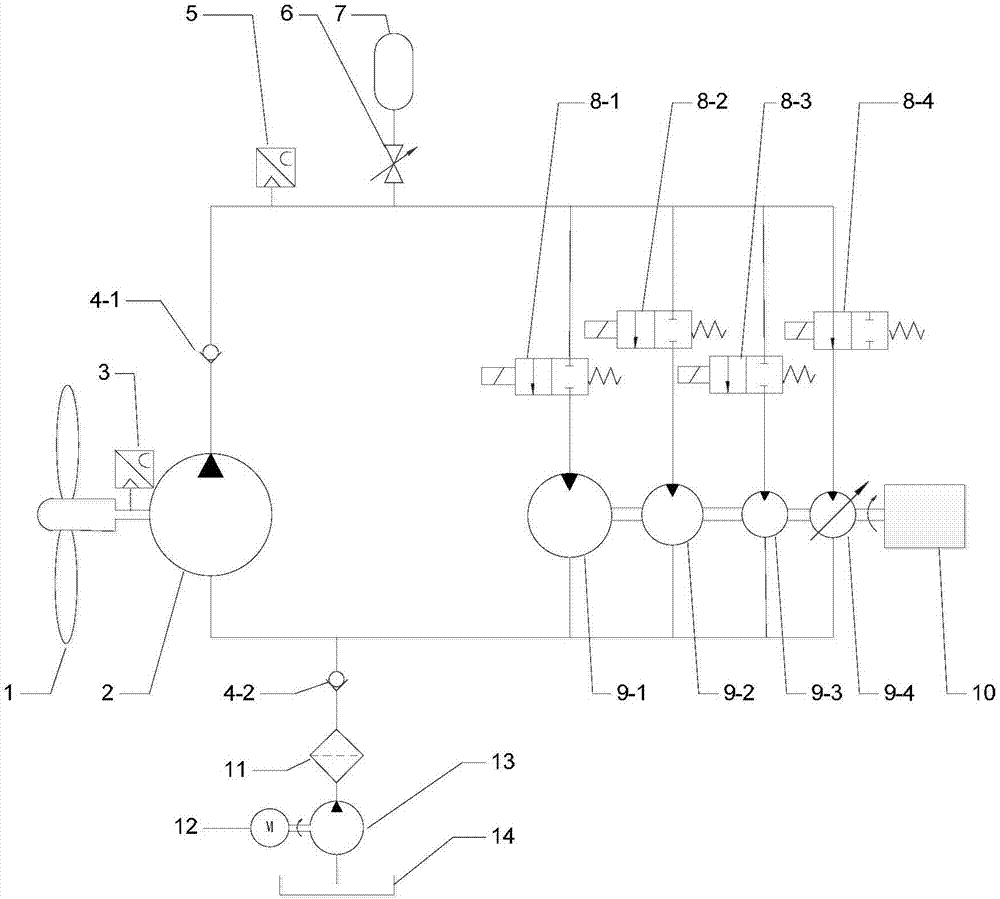

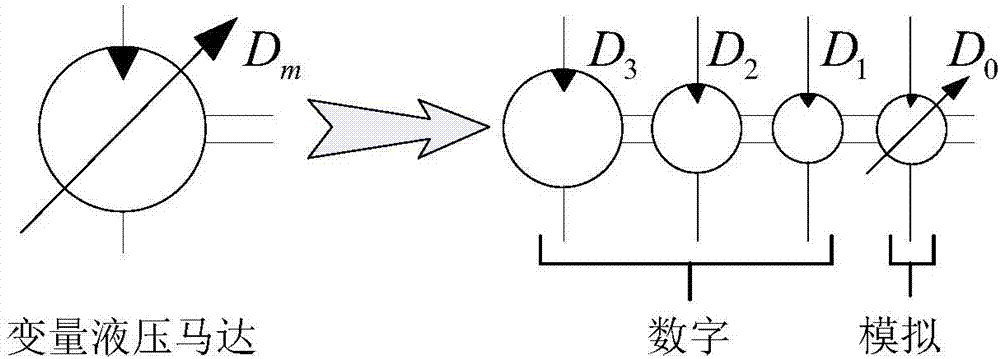

[0025] Such as figure 1 As shown, the digital hydraulic fan drive system implemented in the present invention mainly includes a fan 1, a first quantitative hydraulic pump 2, a speed sensor 3, a pressure sensor 5, a first reversing valve 8-1, and a second reversing valve 8. -2, the third reversing valve 8-3, the fourth reversing valve 8-4, the first quantitative hydraulic motor 9-1, the second quantitative hydraulic motor 9-2, the third quantitative hydraulic motor 9-3, variable Hydraulic motor 9-4, generator 10. The mechanical energy obtained by the fan 1 is transferred to the first quantitative hydraulic pump 2 and converted into hydraulic energy. The first quantitative hydraulic motor 9-1, the second quantitative hydraulic motor 9-2, the third quantitative hydraulic motor 9-3, and the variable hydraulic motor 9-4 converts hydraulic energy into mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com