Quasi-cam-roller type gear pair mechanism and design method thereof

A design method, roller-type technology, applied to mechanical equipment, belts/chains/gears, components with teeth, etc., to achieve precise transmission and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

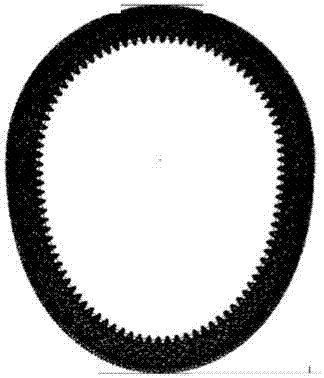

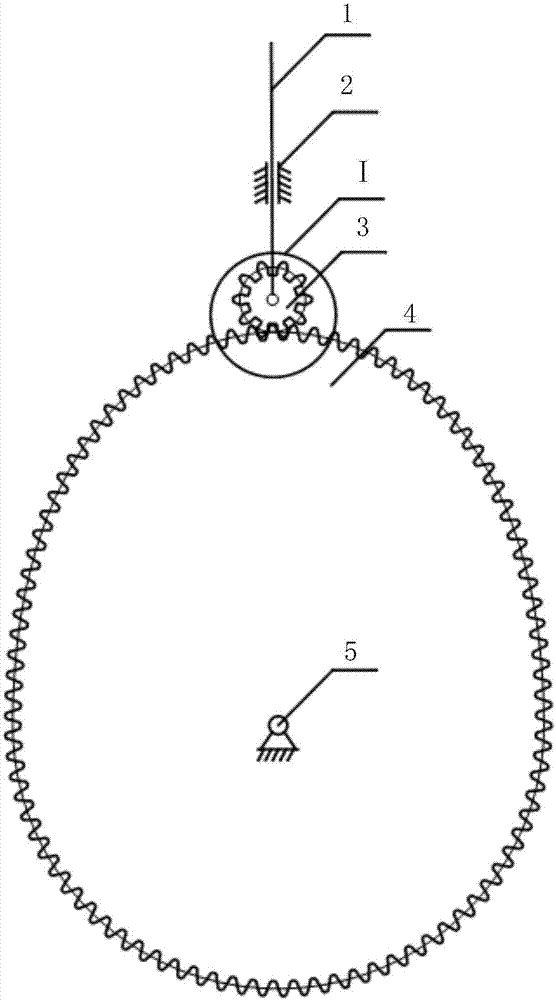

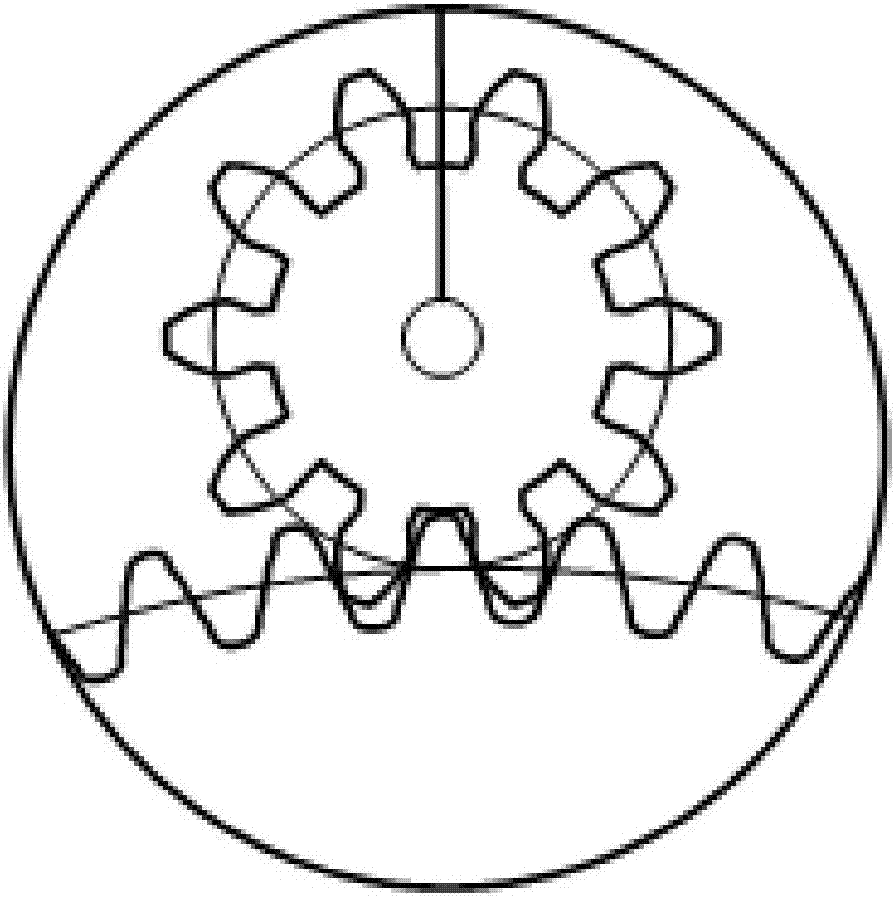

[0068] Such as figure 1 As shown, the cam-like roller gear pair mechanism provided by the embodiment of the present invention includes a driving gear 4, a driven gear 3, a guide rod 1, a slide rail 2 and a frame 5, and the driving gear 4 is installed on the frame 5 , the driving gear 4 rotates around the center of rotation of the frame 5, the driving gear 4 is a non-circular gear, the driven gear 3 is a cylindrical gear, the driven gear 3 meshes with the driving gear 4 and is always in the variable center distance double-sided meshing transmission (gear pair It is a double-sided meshing movement with variable center distance), the guide rod 1 is movably installed on the slide rail 2, and at the same time, one end of the guide rod 1 is connected to the center of the driven gear 3 by screws, and the moving direction of the guide rod 1 is the same as tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com