Heat exchange structure of reactor evaporator

A technology of heat exchange structure and evaporator, which is applied in steam generation, components of steam boilers, steam boilers, etc. It can solve the problems of poor vibration reduction efficiency of anti-vibration strips, achieve good lateral stability and reduce lateral vibration frequency and amplitude, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

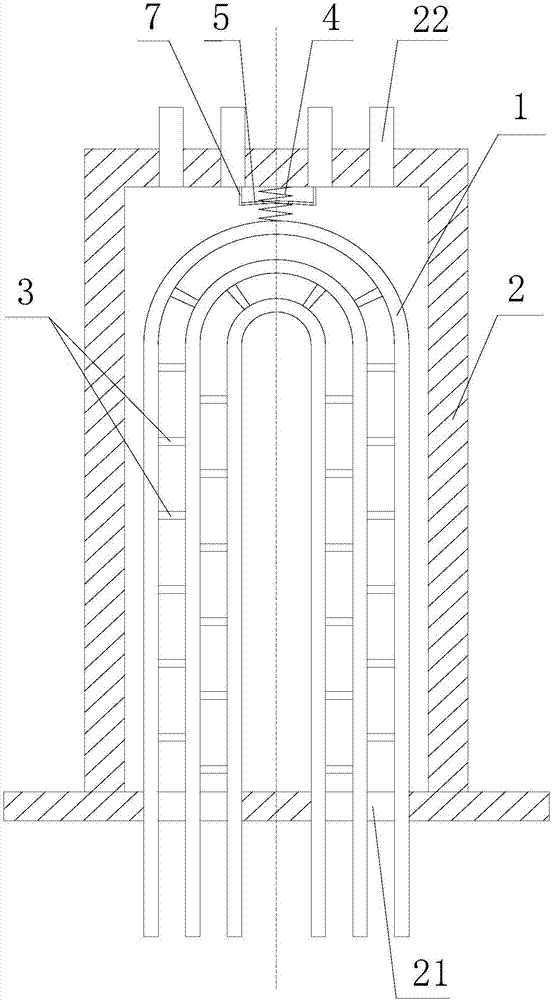

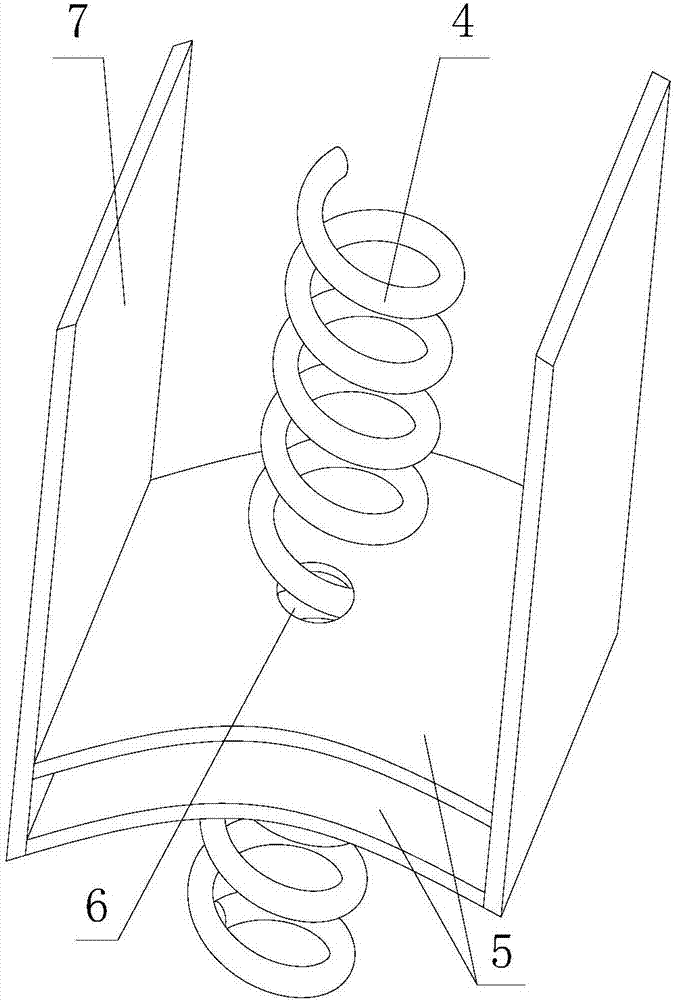

[0022] Such as figure 1 and figure 2 The heat exchange structure of a reactor evaporator shown includes a tube bundle coaming plate 2 and several U-shaped heat transfer tubes 1. The U-shaped heat transfer tubes 1 include straight pipe sections and curved sections. The U-shaped heat transfer tubes 1 The curved section and some straight pipe sections are located inside the tube bundle coaming 2; the tube bundle coaming 2 is also provided with a water inlet flow channel 21 and a water outlet flow channel 22, and two adjacent U-shaped heat transfer tubes 1 are fixed by several connecting rods 3 Connection; also includes a spring 4, one end of the spring 4 is fixedly connected to the inner wall of the tube bundle coaming plate 2, and the other end is fixedly connected to the curved section of the U-shaped heat transfer tube 1, and the axis of the spring 4 and the U-shaped heat transfer tube connected thereto The central symmetry line of 1 is collinear; it also includes a rubber s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com