Boundary discrimination algorithm-based numerical value molding method of mixture

A discriminant algorithm and molding method technology, applied in computing, electrical digital data processing, special data processing applications, etc., can solve the problems of large quantity, high time cost, difficult compaction of test pieces, etc., to reduce the number and time of discrete units. Low cost and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings.

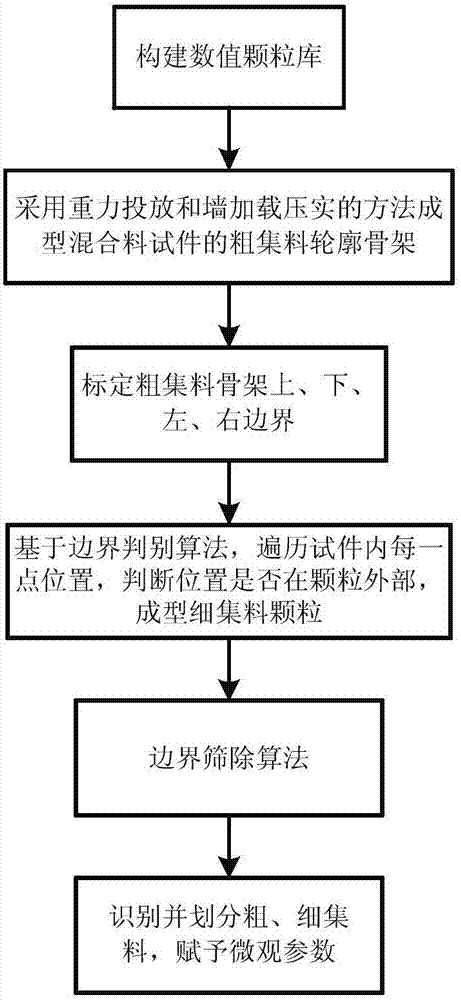

[0052] Such as figure 1 As shown, a kind of mixture numerical forming method based on boundary discriminant algorithm of the present invention comprises the following steps:

[0053] (1) Build a numerical particle library

[0054] The patent CN201610410103.4 is used to construct a numerical particle library, including a two-dimensional particle library or a three-dimensional particle library. The proposed boundary discrimination algorithm is suitable for two-dimensional particles and three-dimensional particles. This example takes the forming of a two-dimensional mixture sample as an example. The forming method and boundary judgment algorithm of 3D specimen are consistent with 2D.

[0055] (2) The coarse aggregate profile skeleton of the mixture specimen is formed by gravity dropping and wall loading and compaction

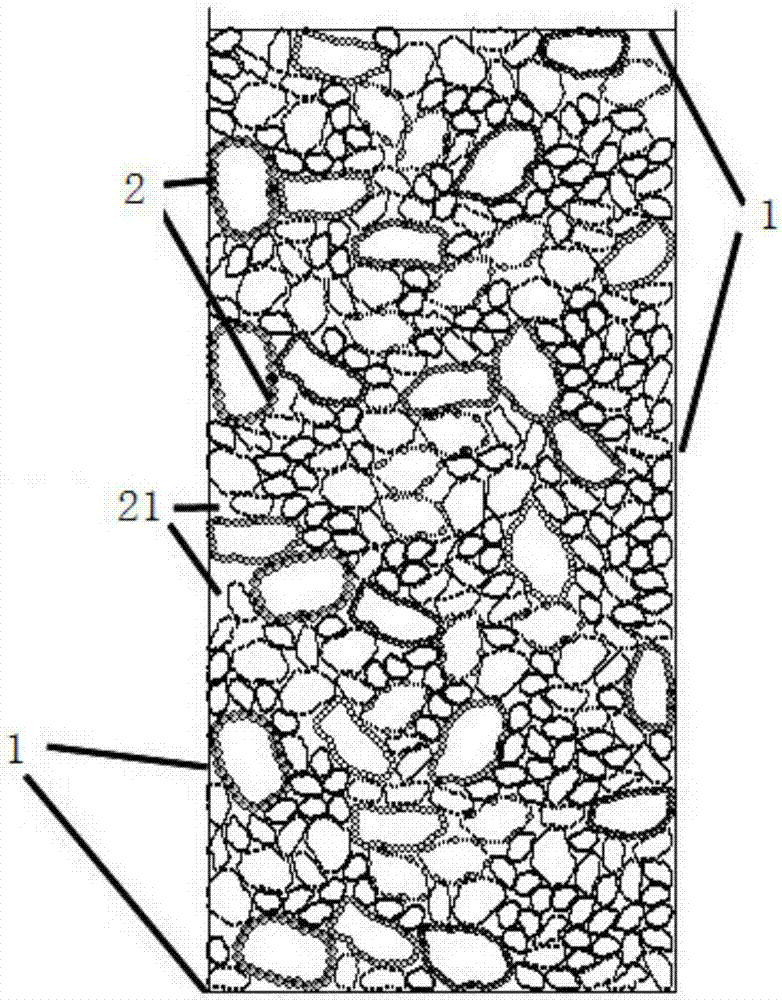

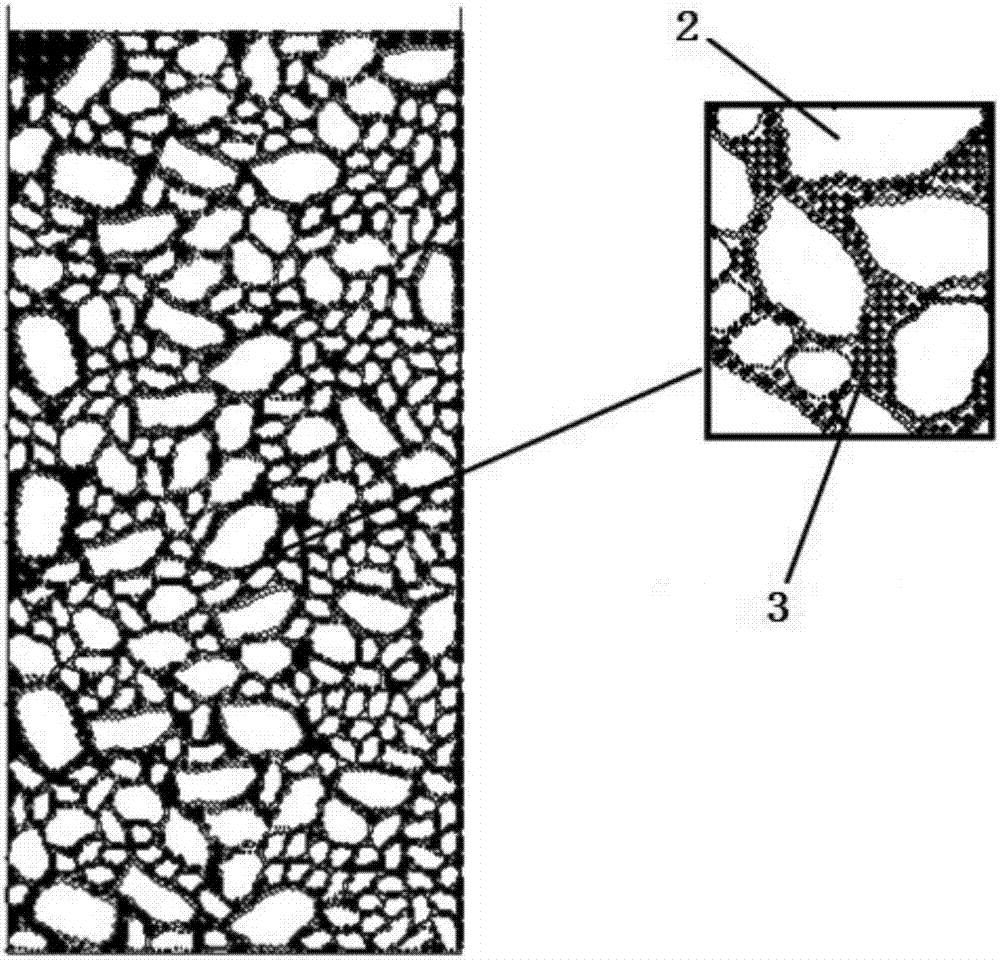

[0056] Such as figure 2 and image 3 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com