Three-dimensional greening structure for bridge pier and construction method of three-dimensional greening structure

A technology of three-dimensional greening and bridge piers, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of limited plant light, difficult maintenance, difficult to control the growth of green plants, etc., and achieve the effect of uniform light and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

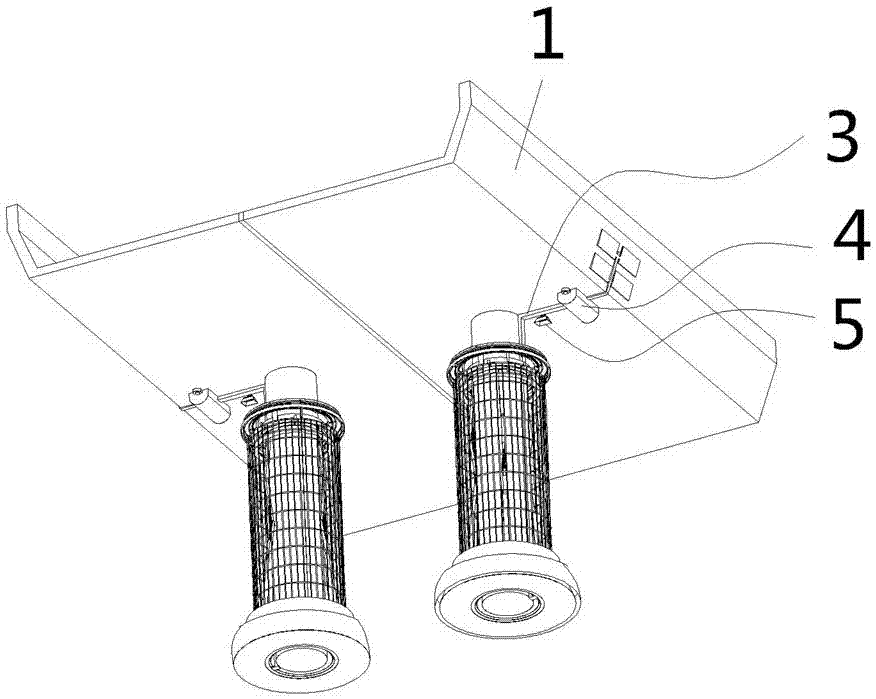

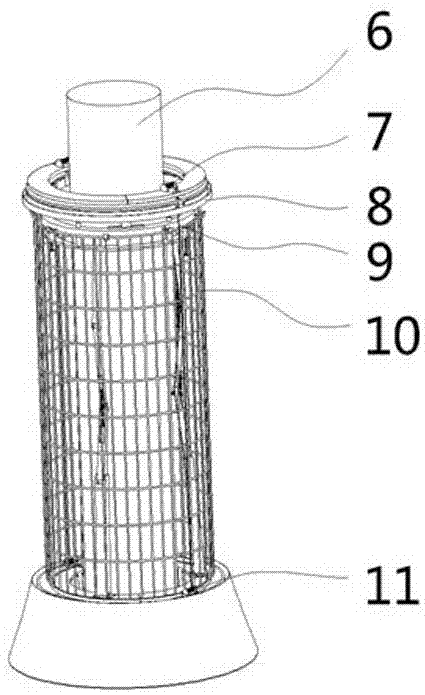

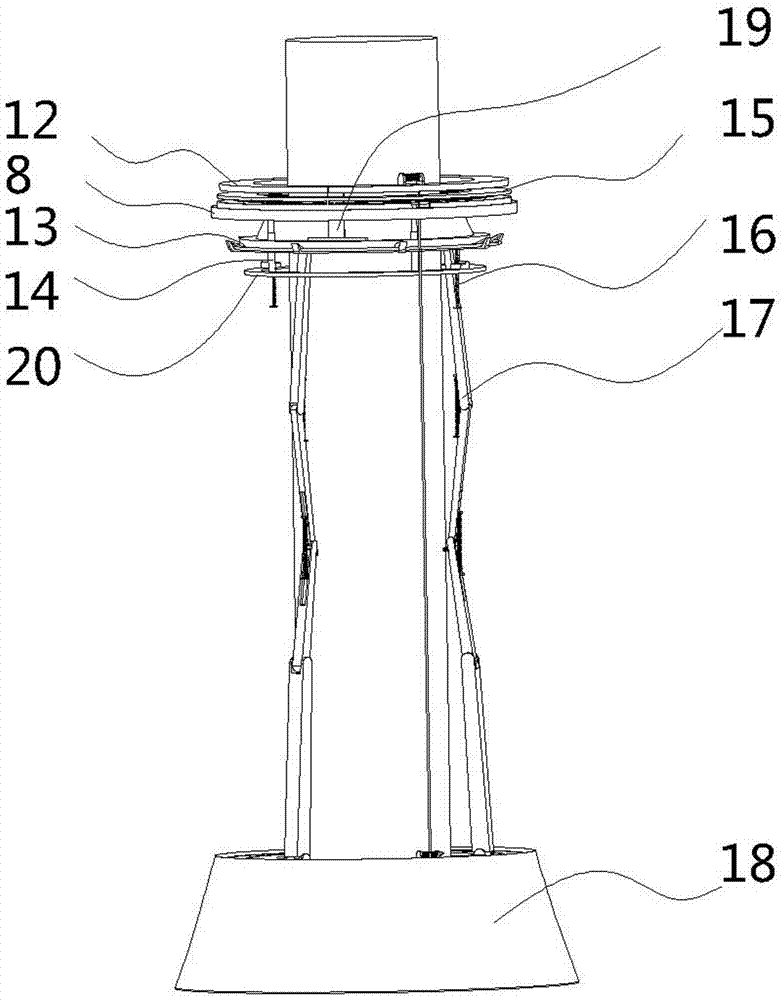

[0034] The three-dimensional greening structure of the bridge pier comprises a bottom coat 18 and a plant planting cover 24 surrounding the pier 6, a motor-driven worm 25 and a slide groove 27 are installed in the bottom coat 18, and the plant is installed in the slide groove 27 The planting sleeve 24 is connected with a rotating sleeve 30 as a whole, the bottom of the rotating sleeve 30 is provided with a worm wheel 26 meshing with the worm 25 , and the bottom of the rotating sleeve 30 is provided with rollers affixed to the slide groove 27 . Plant planting cover 24 is used for planting greening plants, and greening plants are as brocade, creeper, winter jasmine, lingxiao, wisteria, ivy, Fufang rattan, Fujimoto rose, mountain buckwheat, honeysuckle, kite dill, morning glory, stellite, Woody etc. In addition, during the working process of the motor one, since the bottom of the rotating sleeve 30 is provided with a roller and attached to the sliding groove 27, the motor one dri...

Embodiment 2

[0049] The three-dimensional greening structure of the bridge pier comprises a bottom coat 18 and a plant planting cover 24 surrounding the pier 6, a motor-driven worm 25 and a slide groove 27 are installed in the bottom coat 18, and the plant is installed in the slide groove 27 The planting sleeve 24 is connected with a rotating sleeve 30 as a whole, the bottom of the rotating sleeve 30 is provided with a worm wheel 26 meshing with the worm 25 , and the bottom of the rotating sleeve 30 is provided with rollers affixed to the slide groove 27 . Plant planting cover 24 is used for planting greening plants, and greening plants are as brocade, creeper, winter jasmine, lingxiao, wisteria, ivy, Fufang rattan, Fujimoto rose, mountain buckwheat, honeysuckle, kite dill, morning glory, stellite, Woody etc. In addition, during the working process of the motor one, since the bottom of the rotating sleeve 30 is provided with a roller and attached to the sliding groove 27, the motor one dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com