Laser mosquito eradicating machine

A mosquito blower and laser technology, which is applied to the device for capturing or killing insects, application, animal husbandry, etc., can solve problems such as difficult to clean up burnt marks, affect mosquito killing effect, and single function of mosquito killer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

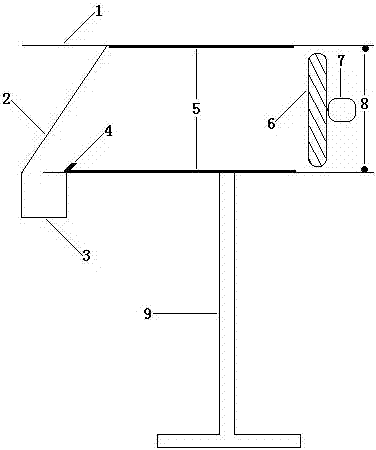

[0009] The laser mosquito killing fan consists of a housing (1), a filter (2), a mosquito storage box (3), a bracket (9), a laser (4), a mosquito trap (8), a reflective surface (5), and a wind blade (6) and the motor (7), the housing is a hollow structure, the reflective surface is installed inside the housing, the emitting end of the laser faces the reflective surface at a corresponding angle, the laser light emitted by the laser is reflected multiple times by the reflective surface, and enters the housing Form multiple laser beams intertwined together, the filter screen is installed on the front of the housing inclined downward, the mosquito storage box is installed on the lower end of the filter screen, the mosquito trap lamp is installed on the rear end of the housing, and the fan blade is installed on the motor. On the rotor, the stator of the motor is mounted on the front of the mosquito trap in the housing.

[0010] The above disclosure is only a specific embodiment of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com