High-efficiency aeration system for MBR process membrane unit

An aeration system and membrane unit technology, applied in the direction of sustainable biological treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problem of easy blockage of aeration holes, uneven aeration, and dead angle of aeration and other problems, to achieve the effect of prolonging the cleaning cycle and service life, ensuring uniformity and stability, and reducing the frequency of switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

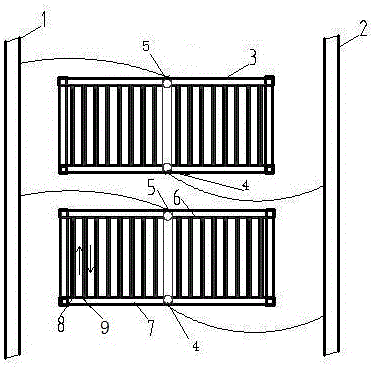

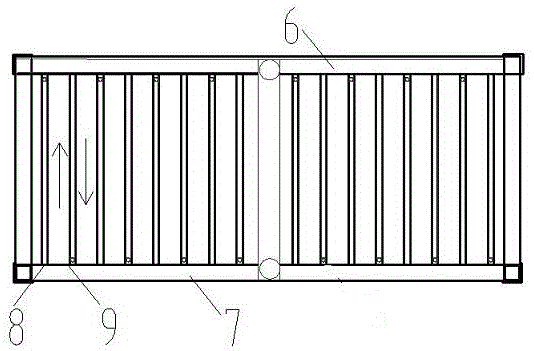

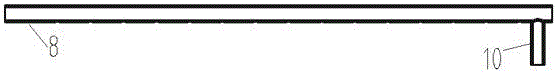

[0022] Such as Figure 1-3 As shown, it includes main aeration pipe one 1, main aeration pipe two 2, at least two sets of membrane racks 3, main aeration pipe one 6 and main aeration pipe two 7 of the membrane rack, and a plurality of branch aeration pipes 8. The main aeration pipe 1 and the main aeration pipe 2 are respectively equipped with electric valves, and the two sides of each set of membrane frames are respectively provided with an air inlet 5 and an air inlet 2 4, and the main aeration pipe 1 and the membrane frame The main aeration pipe 16 is connected through the air inlet 5, the main aeration pipe 2 2 and the main aeration pipe 7 of the membrane frame are connected throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com