Conical aerator

An aeration device and cone-type technology, which is applied in the field of cone-type aeration devices, can solve the problems of high energy consumption and low solubility, and achieve the effect of improving solubility and overcoming low solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

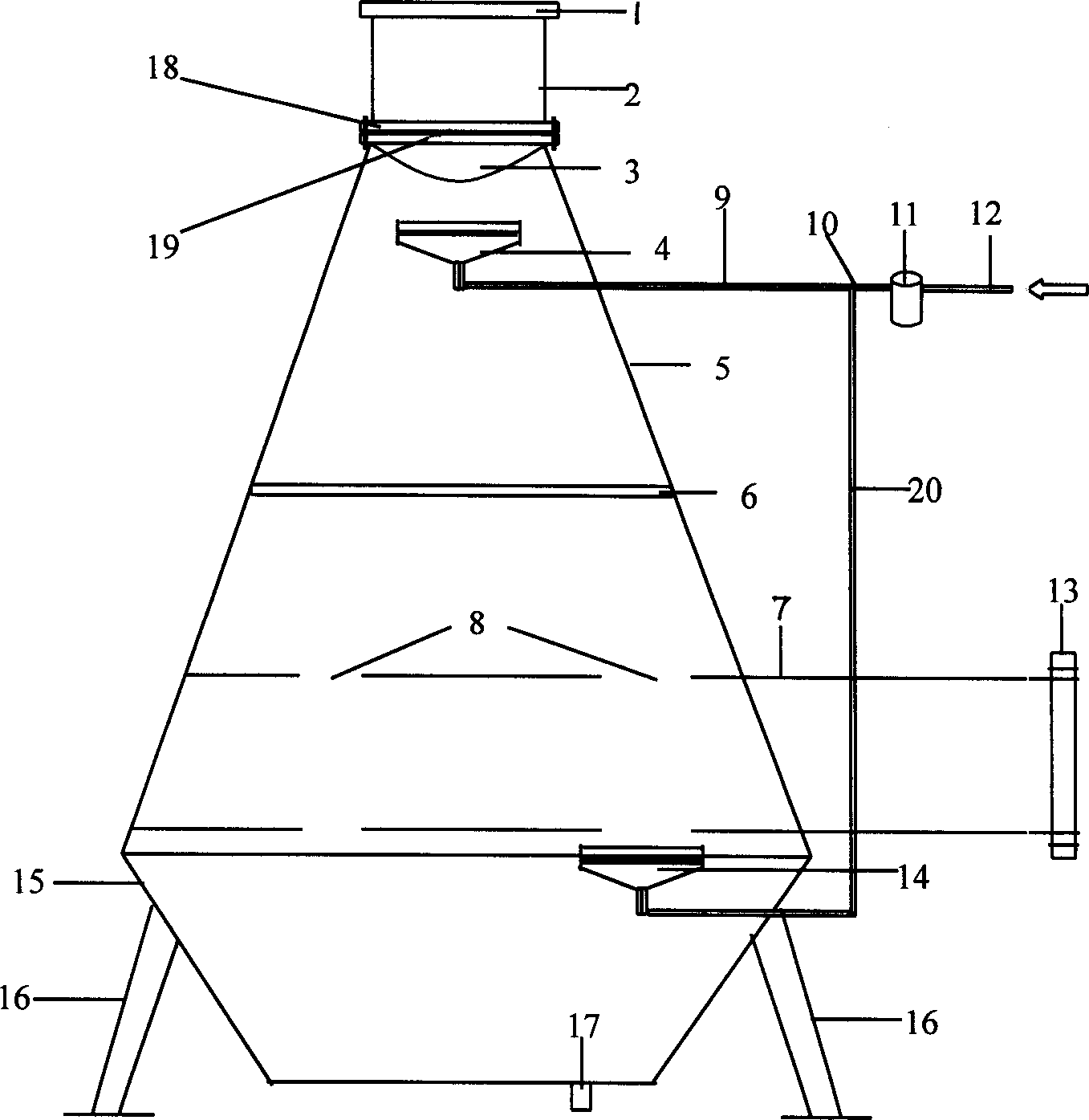

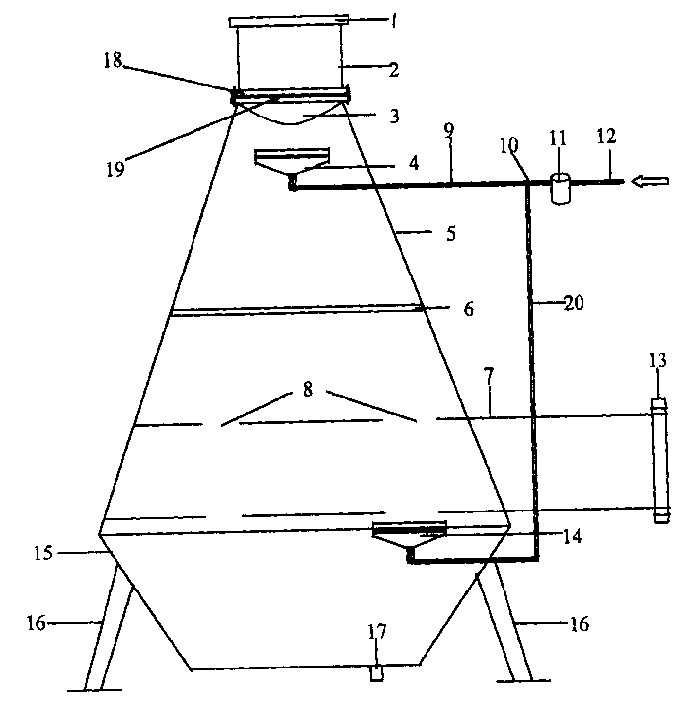

[0012] Such as figure 1 As shown, the conical aerator is composed of a section of cylindrical round pipe 2, a section of gradually expanding truncated cone-shaped outer barrel 5 and a section of tapering truncated truncated outer barrel bottom 15, wherein the round pipe 2 and the outer barrel 5 pass through flange C , D (18, 19) connection, the water flows through the round pipe 2 (there is a flange A1 at the entrance of the pipe), and passes through an inverted hemispherical water distribution plate 3, which is installed on the round pipe 2 The junction with the outer barrel 5 is welded and fixed to flange D19. The water distribution plate 3 is covered with small holes, the diameter of the small holes is 10mm, the hole center spacing is 15mm, and the microporous aerator A4 is set at a height of 150mm from the bottom of the water distribution plate. The diameter of the micropores of the aerator A4 is 100 microns, and its diameter is determined by the amount of water and the requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com