Manufacturing method for moisture-permeable and water-proof shoes

A technology of moisture-permeable waterproof and moisture-permeable waterproof membrane, which is applied in the direction of shoemaking machinery, shoe uppers, footwear, etc., which can solve the problems of heavy weight, inability to drain moisture, and foot load bending resistance, etc., and achieve the effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Before the present invention is described in detail, it should be noted that in the following description, similar elements are represented by the same numbers.

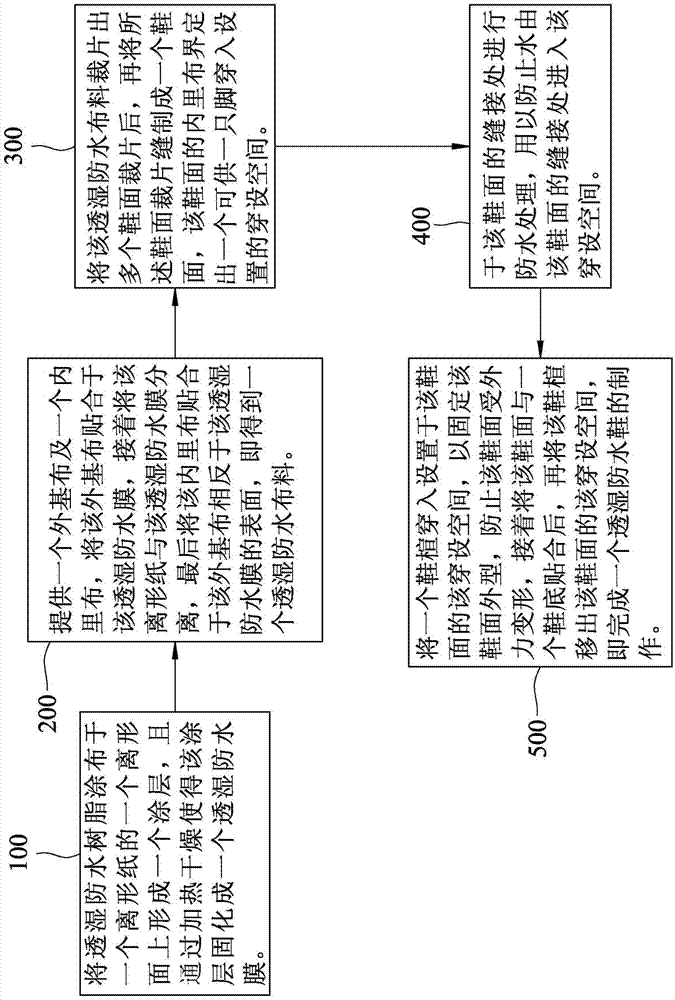

[0037] An embodiment of the method for manufacturing moisture-permeable and waterproof shoes of the present invention includes the following steps:

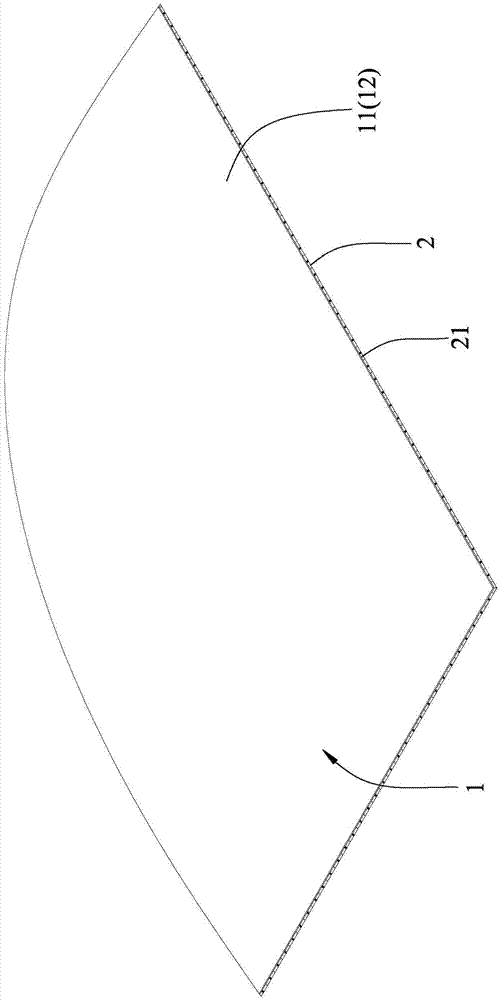

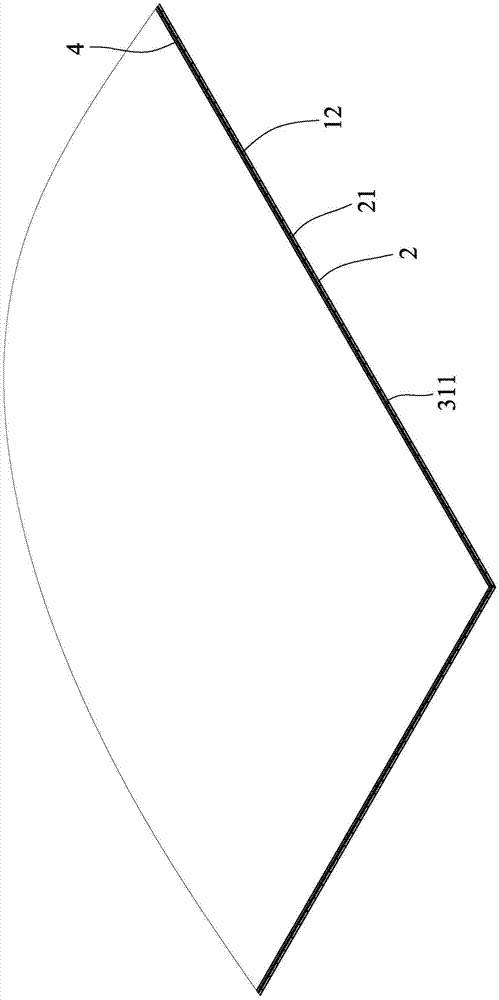

[0038] See figure 1 and figure 2 , Step (A) 100: Coat the moisture-permeable waterproof resin 1 on a release surface 21 of a release paper 2 to form a coating layer 11, and then put the release paper 2 and the coating layer 11 into an oven (Not shown in the figure) at a heating temperature and after a heating time, the coating 11 is heated and dried to form a moisture-permeable waterproof membrane 12, and the thickness of the moisture-permeable waterproof membrane 12 after drying and curing is between 25 μm and 50 μm. In this embodiment, the moisture-permeable and waterproof resin 1 is polyurethane (PU) resin, but it is not limited thereto. The heating temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com