Wear-resisting glove based on knitted spacer fabric

A technology for spacing fabrics and gloves, applied in the field of textile materials, can solve the problems of increasing the cost of raw materials and production labor, increasing the production cost of gloves, reducing the economic value of gloves, etc., and achieves the effects of high cost performance, soft luster and good durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

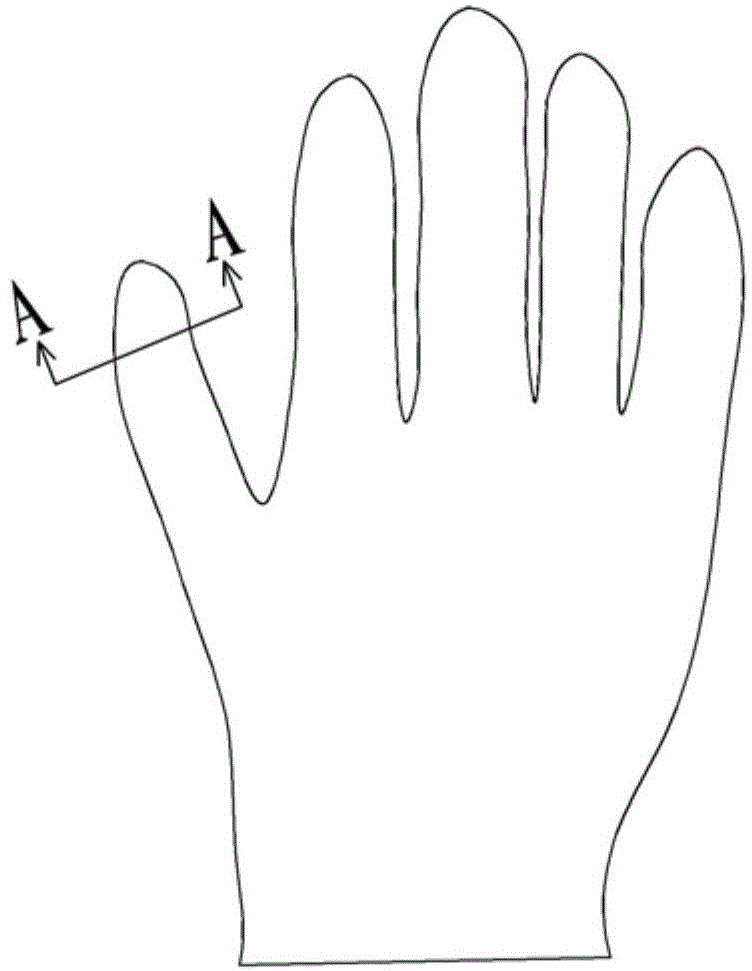

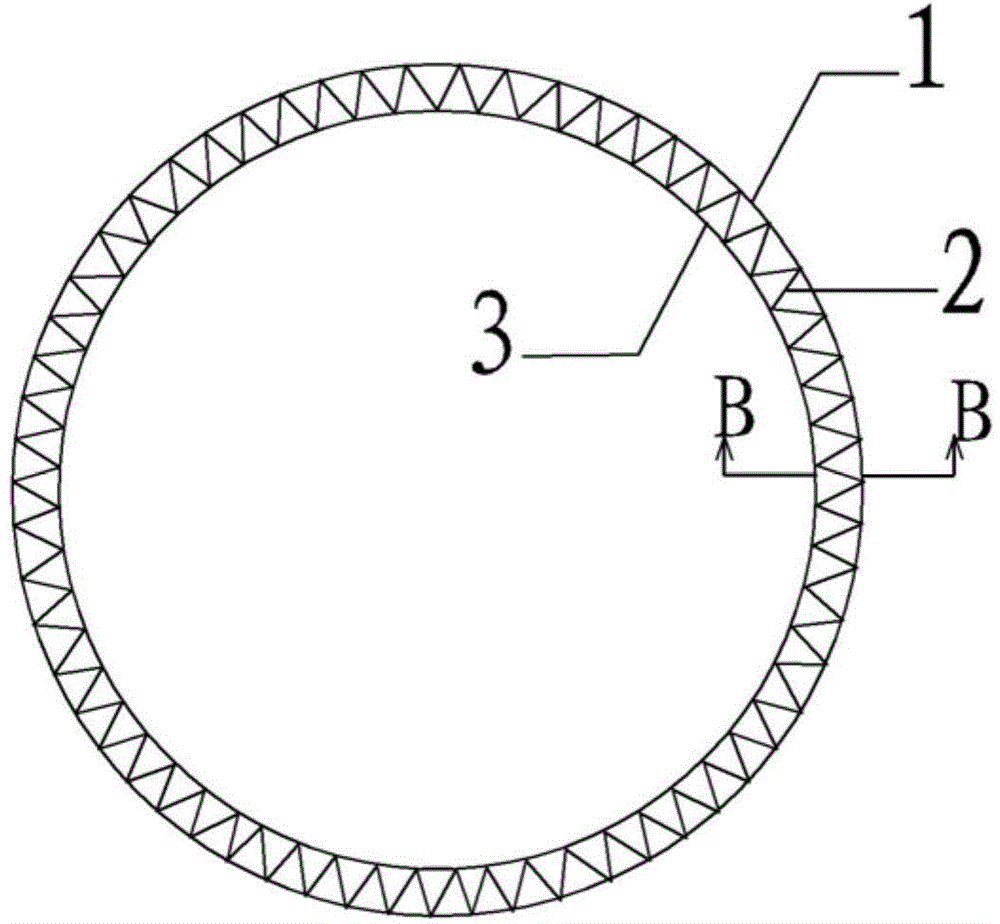

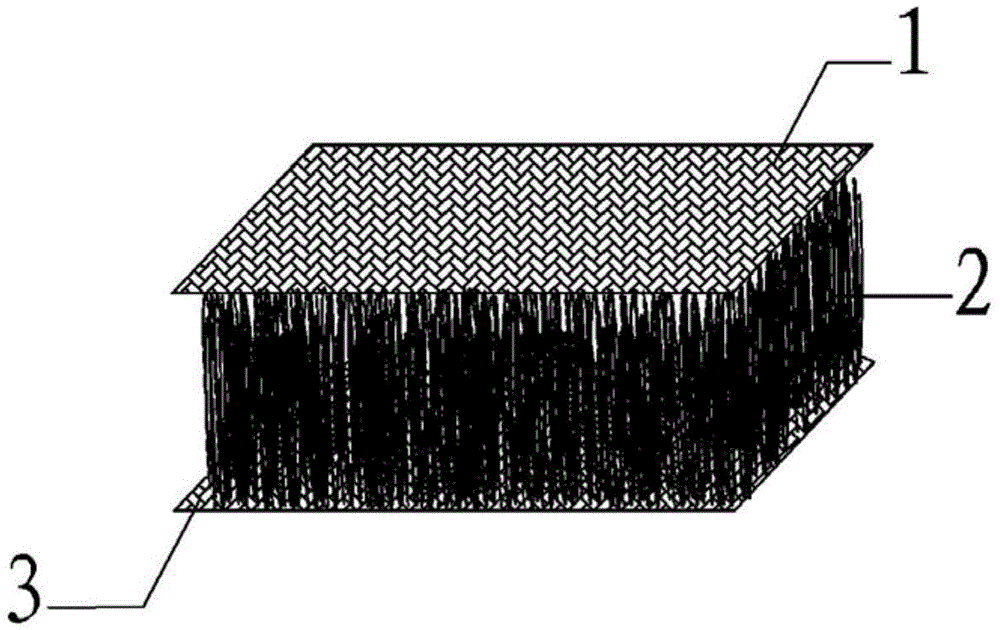

[0029] A wear-resistant glove based on a knitted spacer fabric is made by using the knitted spacer fabric as a raw material through integral molding or semi-mechanical sewing. The knitted spacer fabric includes an upper surface, a middle connection layer and a lower surface. The upper surface is a polyester strong fabric composed of 200dtex polyester high-strength yarn, wherein the breaking strength of the polyester high-strength yarn is 9.3CN / dtex, and the elongation at break is 9%; the middle The connecting layer is composed of polyurethane fibers of 56dtex; the lower surface is a polyester elastic fabric composed of 66.7dtex polyester elastic SSY fibers, wherein the elastic elongation of the polyurethane fibers is 500%, and the breaking strength is 7.6CN / dtex. The middle connection layer is perpendicular to the upper surface and the lower surface, connects the upper surface and the lower surface, and does not use adhesive to bond to obtain a knitted spacer fabric.

[0030] ...

Embodiment 2

[0032] A wear-resistant glove based on a knitted spacer fabric is made by using the knitted spacer fabric as a raw material through integral molding or semi-mechanical sewing. The knitted spacer fabric includes an upper surface, a middle connecting layer and a lower surface. The upper surface is a polyester strong fabric composed of 350dtex polyester high-strength yarn, wherein the breaking strength of the polyester high-strength yarn is 10.1CN / dtex, and the elongation at break is 10%. The connecting layer is made of 87dtex polyurethane fiber to form the polyurethane connecting layer; the lower surface is a polyester elastic fabric made of 89.4dtex polyester elastic SSY fiber, wherein the elastic elongation of the polyurethane fiber is 750%, and the breaking strength is 8.5CN / dtex. The middle connection layer is perpendicular to the upper surface and the lower surface, connects the upper surface and the lower surface, and does not use adhesive to bond to obtain a knitted spacer...

Embodiment 3

[0035] A wear-resistant glove based on a knitted spacer fabric is made by using the knitted spacer fabric as a raw material through integral molding or semi-mechanical sewing. The knitted spacer fabric includes an upper surface, a middle connection layer and a lower surface. The upper surface is a polyester strong fabric composed of 275dtex polyester high-strength yarn, wherein the breaking strength of the polyester high-strength yarn is 9.8CN / dtex, and the elongation at break is 9.5%. The connecting layer is composed of polyurethane fibers of 78dtex; the lower surface is a polyester elastic fabric composed of 76.4dtex polyester elastic SSY fibers, wherein the elastic elongation of the polyurethane fibers is 590%, and the breaking strength is 7.9CN / dtex. The middle connection layer is perpendicular to the upper surface and the lower surface, connects the upper surface and the lower surface, and does not use adhesive to bond to obtain a knitted spacer fabric.

[0036] The knitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com