Preparation method of cotton-polyester double-sided jacquard fabric containing SORONA filaments

A technology of jacquard cloth and cotton-polyester, which is applied in the field of preparation of cotton-polyester double-sided jacquard cloth, which can solve the problems of high shrinkage rate and low pilling level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

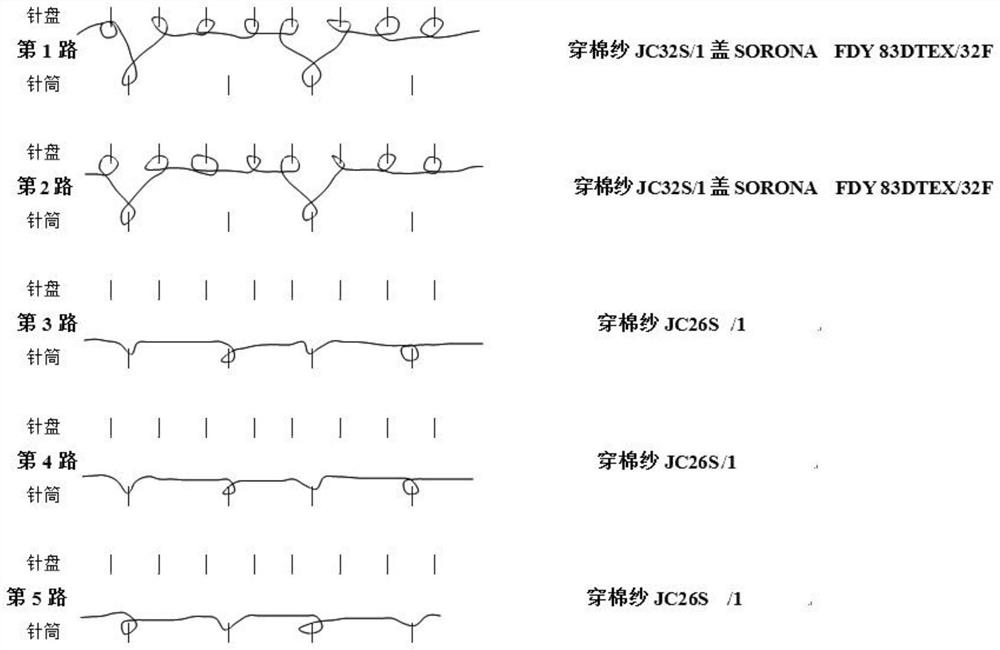

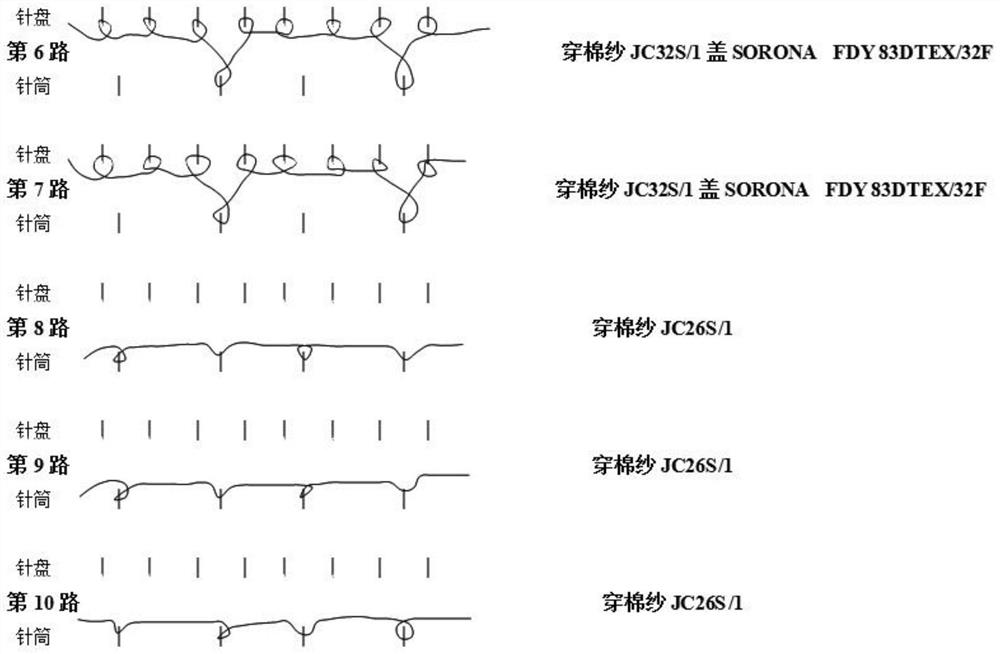

[0044] see Figure 1-9 , a preparation method of a cotton-polyester double-sided jacquard fabric containing SORONA filament in this embodiment, the cotton-polyester double-sided jacquard fabric comprises the first cotton yarn, the second cotton yarn and SORONA two-component composite filament,

[0045] In this embodiment, the cotton yarn is Xinjiang cotton, the first cotton yarn is cotton yarn JC32S / 1, the second cotton yarn is cotton yarn JC26S / 1, and the SORONA two-component composite filament is FDY 83DTEX / 32F.

[0046] Weaving equipment parameters are:

[0047] Machine type: double-sided weft knitting large circular machine

[0048] Machine number: 19 needles / 25.4mm

[0049] Barrel diameter: 864mm (34")

[0050] Machine speed: 20r / min

[0051] Number of channels: 72F

[0052] Specifically include the following steps:

[0053] (1) Weaving: Weave the above raw materials in a double-sided weft knitting machine to obtain a gray cloth, and the weight of the gray cloth is ...

Embodiment 2

[0085] A kind of preparation method of cotton-polyester double-sided jacquard cloth containing SORONA filament, the difference with embodiment 1 is: in the present embodiment, the bath ratio in pretreatment, dyeing and posttreatment is 1:10.

[0086] (1) Weaving is the same as in Embodiment 1.

[0087] (2) pretreatment: same as embodiment 1.

[0088] (3) Pre-processing:

[0089] Smelting: Put the gray cloth after the final blank into the tank, add water, add Na 2 CO 3 solution, heated up to 90°C, simmered in circulation for 30 minutes, then cooled to 40°C and drained;

[0090] Erosion: the boiled fabric is in the dyeing vat, add water and polishing enzyme 600N to the dyeing vat, the dosage is 0.05%, ferment wash the scalded fabric at a temperature of 50°C, add Na 2 CO 3 And heat to inactivate the polishing enzyme 600N, then drain.

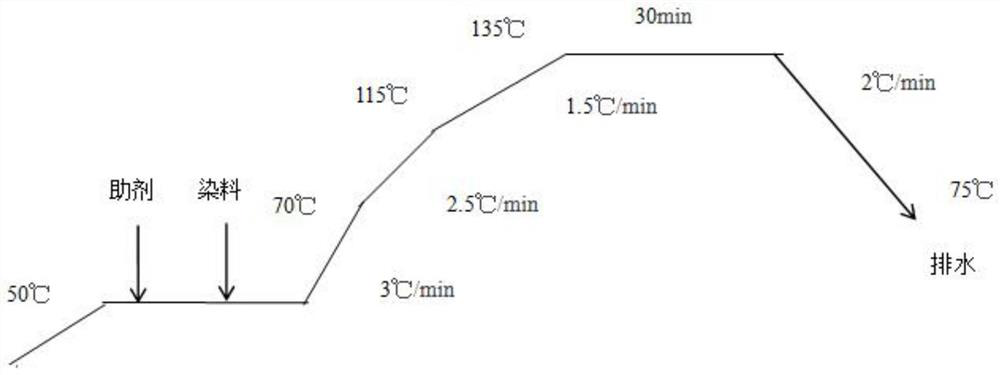

[0091] (4) Dyeing:

[0092] High-temperature dyeing of polyester fiber: After the wool is etched, the fabric is placed in the dyeing vat, a...

Embodiment 3

[0099] A kind of preparation method of cotton-polyester double-sided jacquard cloth containing SORONA filament, and the difference of embodiment 1 is: in the present embodiment, the bath ratio in pretreatment, dyeing, posttreatment is 1:20.

[0100] (1) Weaving is the same as in Embodiment 1.

[0101] (2) pretreatment: same as embodiment 1

[0102] (3) Pre-processing:

[0103] Smelting: Put the gray cloth after the final blank into the tank, add water, add Na 2 CO 3 Solution, heated up to 80°C, simmered in circulation for 60 minutes, then cooled to 60°C and drained;

[0104] Erosion: the scoured fabric is in the dyeing vat, add water and polishing enzyme 600N to the dyeing vat, the dosage is 0.1%, ferment wash the scalded fabric at a temperature of 60°C, add Na 2 CO 3 And heat to inactivate the polishing enzyme 600N, then drain.

[0105] (4) Dyeing:

[0106] High-temperature dyeing of polyester fiber: the fabric after the wool is etched is in the dyeing vat, add water t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Barrel diameter | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com