Medical wrapping cloth with high bacterium blocking performance and preparation method

A technology of wrapping cloth and high resistance, applied in the field of medical and health fiber materials, can solve the problems of difficult to popularize and use, reduced antibacterial performance, poor microbial barrier effect, etc., and achieves excellent tensile strength and antibacterial performance. The effect of high antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

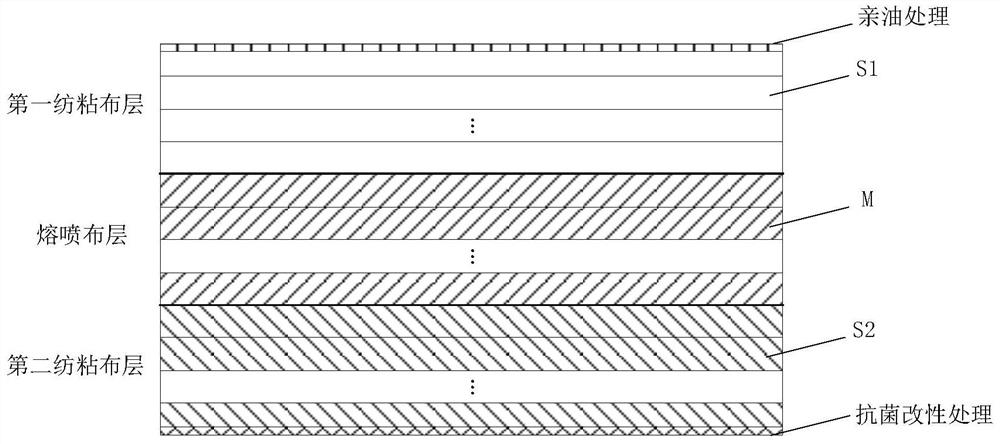

[0048] This embodiment provides a medical wrapping cloth with high resistance to bacteria, such as figure 1 As shown, it includes a first spunbond layer, a meltblown layer and a second spunbond layer connected in sequence from outside to inside;

[0049] The first spunbond layer includes at least one layer of first spunbond S1;

[0050] The melt-blown cloth layer is at least one layer of melt-blown cloth M that includes a plurality of melt-blown multi-pile fibers containing graphene particles that are intertwined with each other;

[0051] The second spunbond cloth layer includes at least one layer of second spunbond cloth S2, the inner surface of the second spunbond cloth of the innermost layer is treated with polyvinyl alcohol antibacterial modification, and the inner surface is usually used as the packaging bag made of the inner wall.

[0052]The above-mentioned medical wrapping cloth with high resistance to bacteria is designed in layers, and a meltblown cloth layer is in...

Embodiment 2

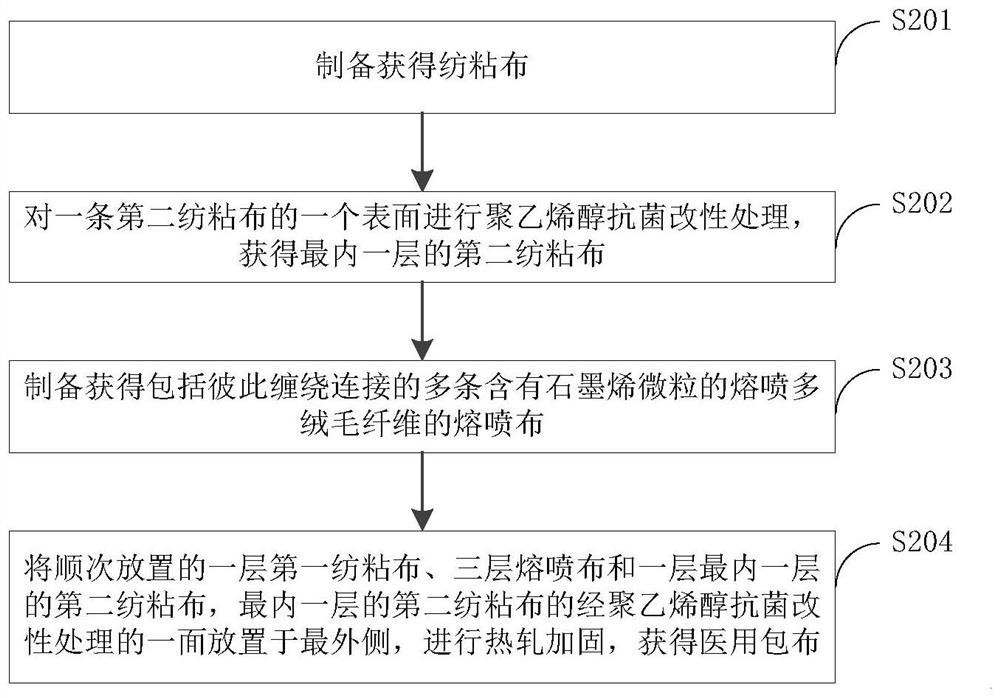

[0059] This example provides a preparation method of the medical wrapping cloth with high resistance to bacteria performance in Example 1, taking the medical wrapping cloth with high resistance to bacteria performance of the S1-M-M-M-S2 structure in Example 1 as an example, that is, the medical wrapping cloth The cloth has a connected layer of first spunbond cloth S1, three layers of melt blown cloth M and one layer of second spunbond cloth S2 in sequence from the outside to the inside, such as image 3 Shown, preparation method comprises the following steps:

[0060] S201. Prepare and obtain spunbond fabrics, which are respectively used as the first spunbond fabric S1 and the second spunbond fabric S2;

[0061] S202. Perform polyvinyl alcohol antibacterial modification treatment on one surface of the second spunbond fabric S2 to obtain the innermost second spunbond fabric;

[0062] S203, preparing and obtaining a melt-blown cloth comprising a plurality of melt-blown multi-pi...

example 1

[0090] Sample 1 was prepared using the following steps:

[0091] Mix the polyolefin copolymer and spunbonded polypropylene raw materials with a mass ratio of 13:56 evenly, and melt and extrude them through a screw extruder. The screw temperature is 226 ° C, the melt pipe temperature is 232 ° C, and the die head temperature is 236 ℃, apply an airflow with an air volume of 2300Pa and an air temperature of 20°C to the melt-extruded fibers for stable drafting, obtain fine denier fibers and receive them uniformly, and obtain spunbond fabrics;

[0092] One side of a piece of spunbond cloth is fixed on a glass plate, and the glass plate and the spunbond cloth pass through the space evenly distributed with foggy polyvinyl alcohol antibacterial liquid at a constant speed, so that the spunbond cloth stays in the space for a total of 6 minutes, and the modified surface spun cloth is obtained. Sticky cloth, dry the modified surface spunbond cloth at 65°C for 8 minutes to obtain the spunbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com