Electronic equipment safe cleaning device

A technology for cleaning devices and electronic equipment, which is applied in the direction of removing smoke and dust, cleaning methods and appliances, and cleaning methods using gas flow, etc. It can solve problems such as hidden dangers in the operation of electronic equipment, low degree of automation, and internal short circuits, so as to prevent the body from being damaged. Damage, high degree of automation, and the effect of preventing dust residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

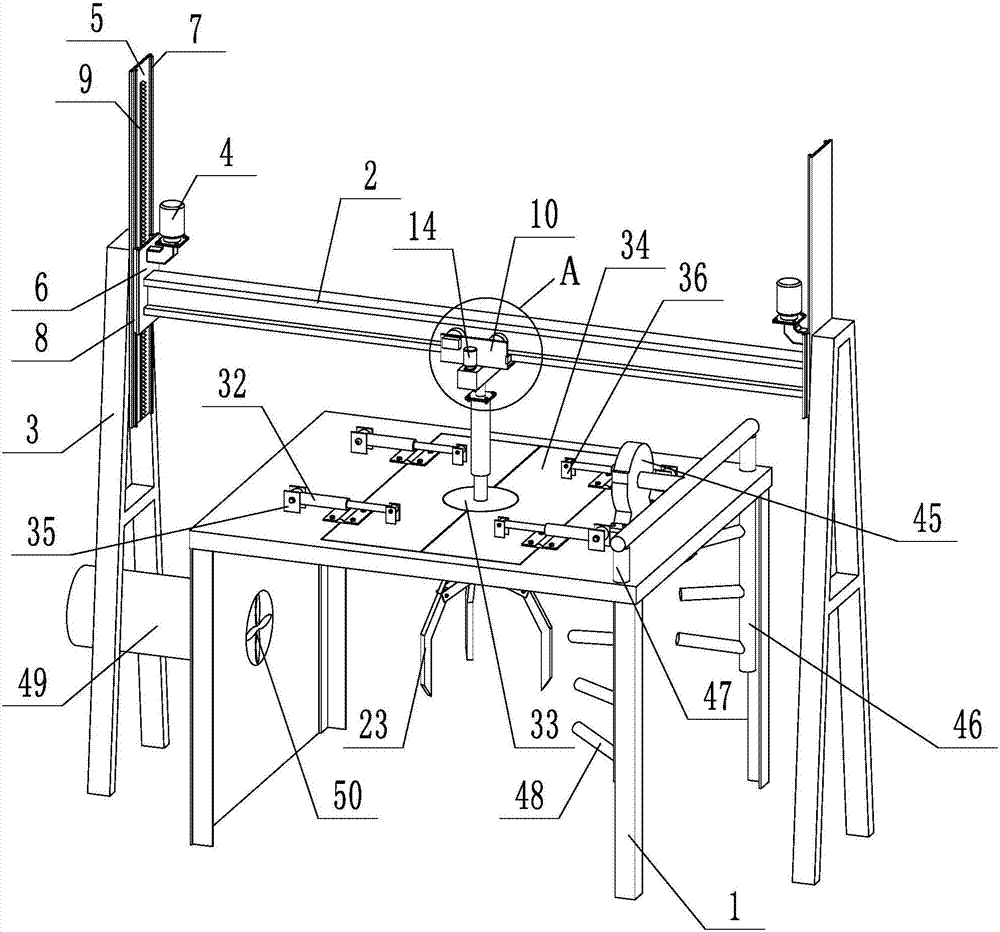

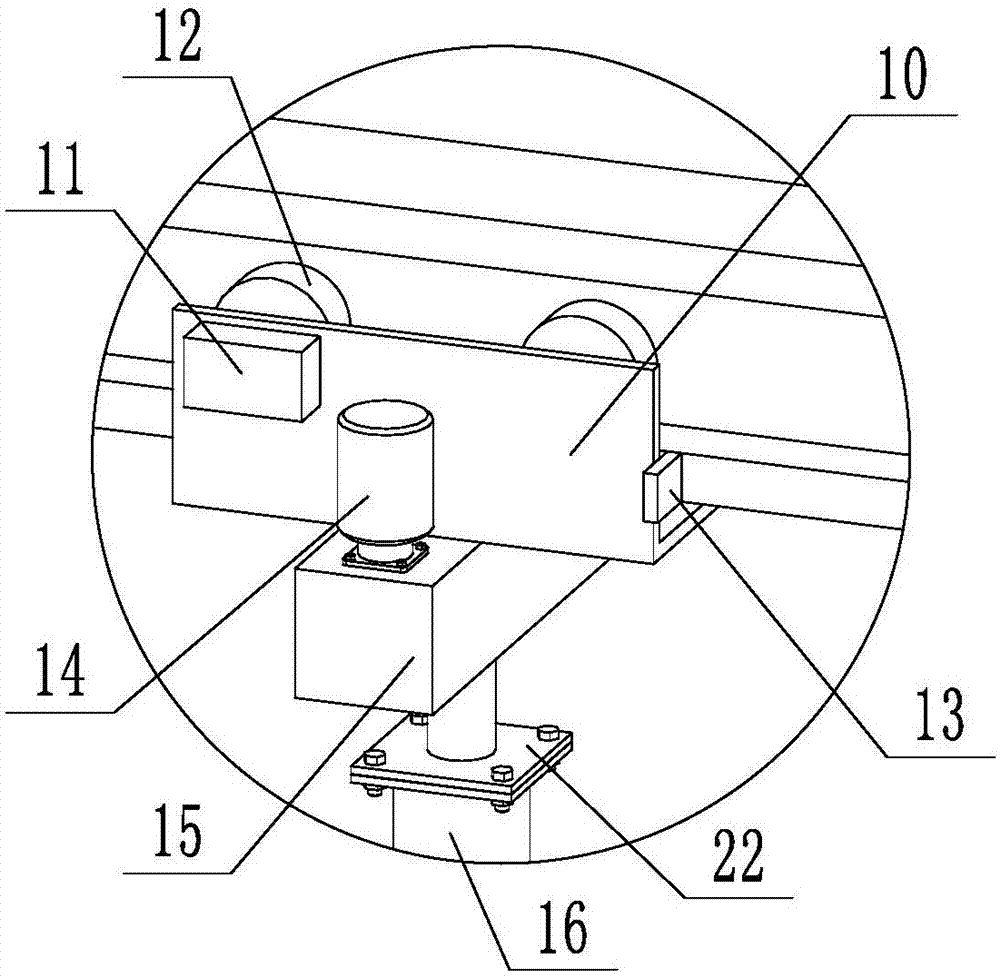

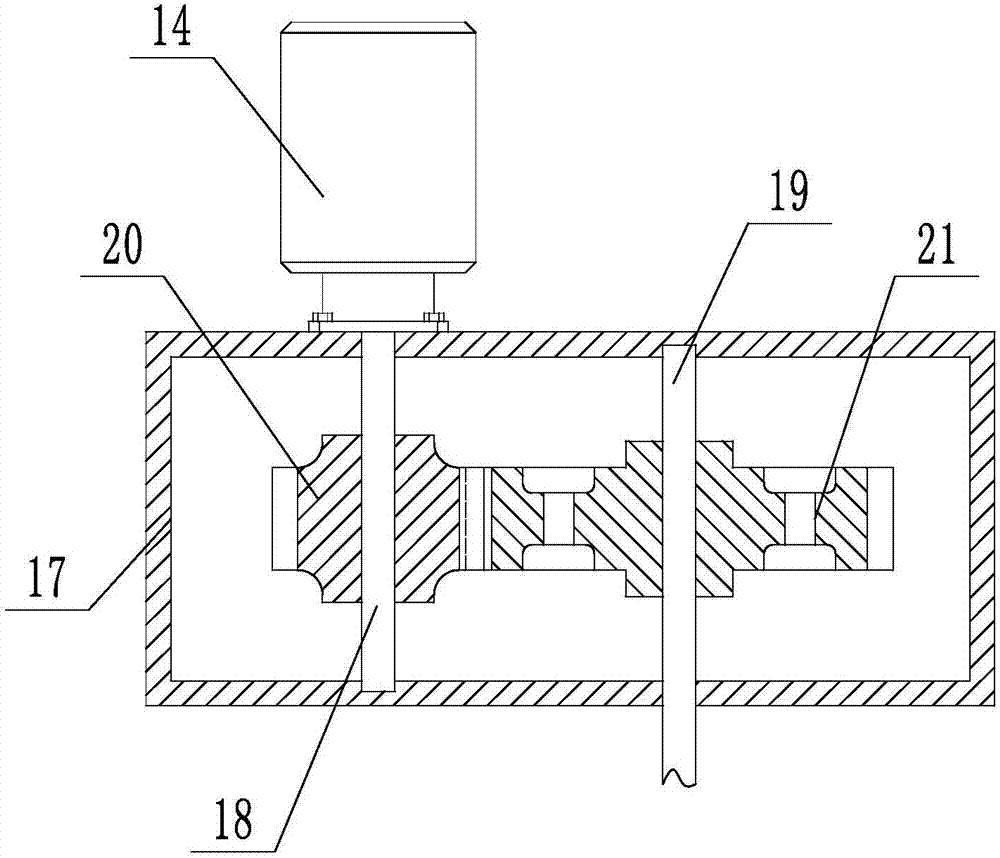

[0040] according to Figure 1 to Figure 6As shown, a safety cleaning device for electronic equipment includes a box body 1, a transport mechanism, an opening and closing mechanism, an air blowing mechanism, a dust collection and discharge mechanism, and monitoring equipment. The opening and closing mechanism, the air blowing mechanism, and the monitoring equipment are supported on the box body 1 Above, the dust collection and discharge mechanism is located at the left end of the box and communicates with the inner cavity of the box. The transportation mechanism includes a beam 2, a support beam 3, a beam lifting mechanism, a walking mechanism, a lifting and rotating mechanism, and a clamping mechanism. The beam 2 and the support beam 3 The sliding connection between them is through the beam lifting mechanism, the traveling mechanism and the lifting and rotating mechanism are supported on the beam 2, and the clamping mechanism is installed at the lower end of the lifting and rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com