Signal tower body repairing equipment

A technology for repairing equipment and signal towers, which is applied to the field of repairing equipment for signal towers and towers, can solve the problems of increased danger, wasted time, and the safety of maintenance workers cannot be guaranteed, and achieves the effect of improving maintenance efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

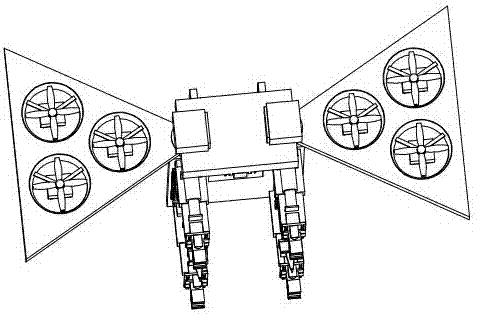

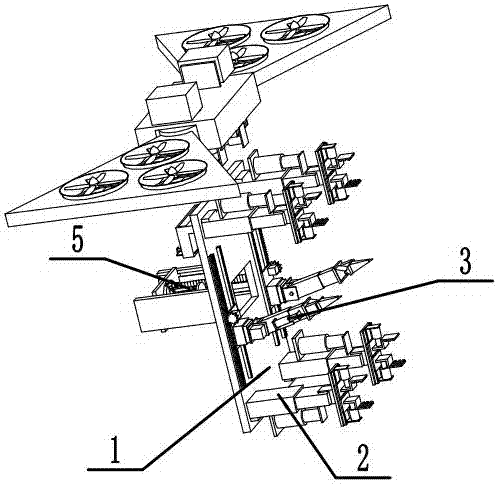

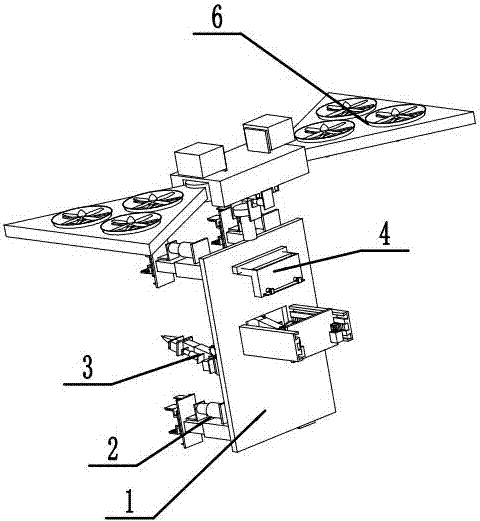

[0021] Example figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 As shown, a signal tower body maintenance equipment includes a base 1, four fixed parts 2, two welding parts 3, a steel pipe storage part 4, a steel pipe moving part 5, and a flight part 6, and is characterized in that: the four The upper ends of the first telescopic sleeves 201 of each fixed part 2 are respectively fixedly connected with the four fixed part fixing seats 108; the four sliding bars 302 of the two welding parts 3 are slidably installed in the four second dovetail grooves 110 respectively. Here, the two first gears 319 are respectively meshed with the two second racks 109; the back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com