Constructs, strains and methods for producing carbohydrates using Synechococcus utex2973

A technology of compounds and microbial strains, applied in the field of biomanufacturing, can solve the problems of high cost of lignin and cellulose degradation and transformation, no cost advantage, etc., and achieve the effect of increasing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

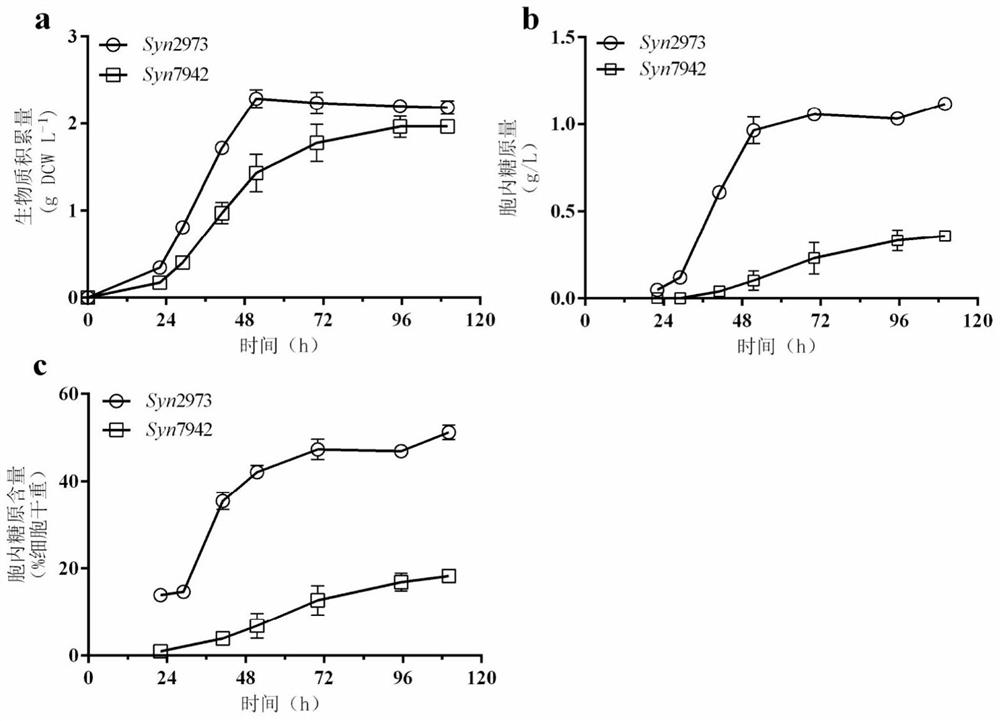

[0059] Example 1: Production of glycogen with Synechococcus UTEX2973

[0060] 1. Experimental steps

[0061] (1) Cultivate Synechococcus sp. UTEX2973 and PCC7942 wild-type algae strains in a column photoreactor: ordinary glass tube, column height 580mm, diameter 30mm, liquid volume 150mL (can hold about 300mL). Initial inoculum concentration OD 730 0.05, the culture medium is BG11 medium (BG11 medium composition is 1.5g / L NaNO 3 ,40mg / L K 2 HPO 4 ·3H 2 O,36mg / L CaCl 2 2H 2 O, 6mg / L citric acid, 6mg / L ferric ammonium citrate, 1mg / L EDTA disodium salt, 20mg / L NaCO 3 ,2.9mg / L H 3 BO 3 ,1.8mg / L MnCl 2 4H 2 O,0.22mg / L ZnSO 4 ·7H 2 O,0.39mg / L NaMoO 4 2H 2 O,0.079mg / LCuSO 4 ·5H 2 O and 0.01mg / L CoCl 2 ·6H 2 O); at 38°C, 250μE / m 2 / s light, 3% CO 2 Air for cultivation. During the incubation, samples were taken to test the OD 730 and glycogen content. And cyanobacteria biomass (Dry cell weight, DCW, cell dry weight) content is by 1ml OD 730 The algal cells of =...

Embodiment 2

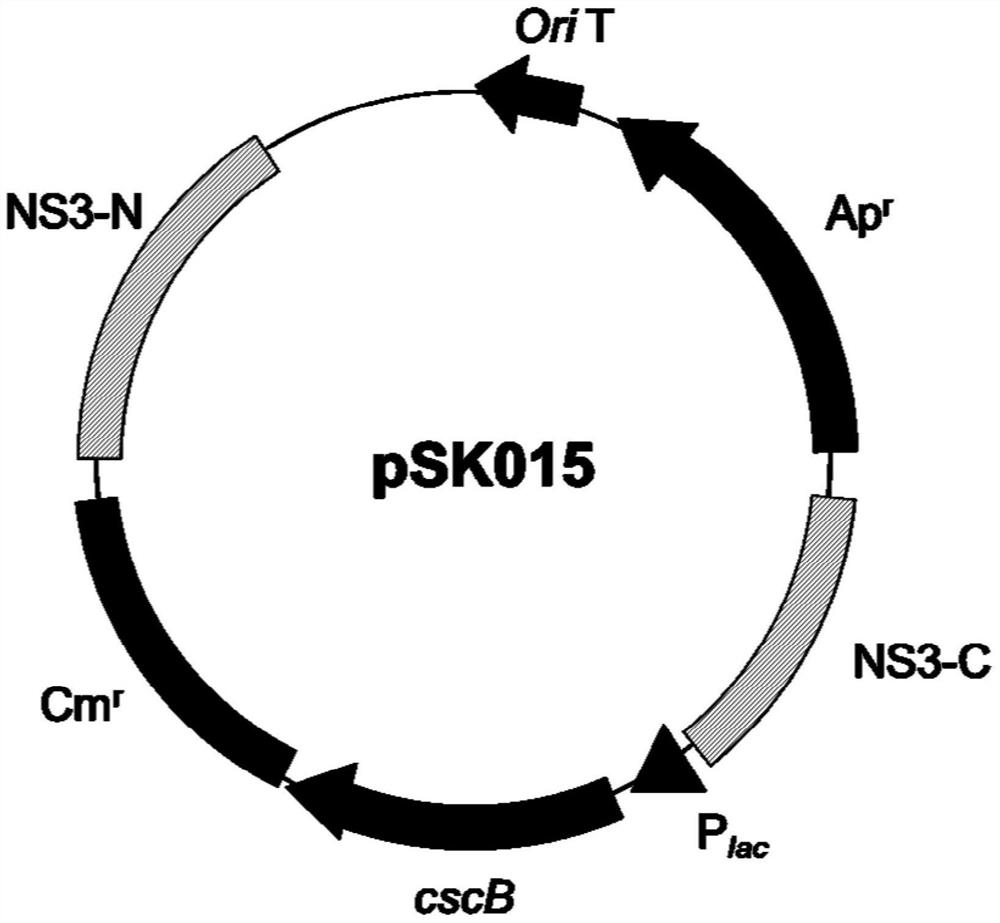

[0065] Example 2: Construction of vector pSK015 for introduction into Synechococcus UTEX2973

[0066] Using NS3-F (5'-TCAGCCAGCTCGTCGTGATGTCGAAACCCAAGCC-3') and NS3-R (5'-ACAGTCGGCGTCACGGCAACTTGCTCCGCGTAGG-3') as a primer pair, PCR amplification was performed using plasmid pNS3-3B with cscB (Ducat et al.2012) as a template; And the PCR product was connected with the pBR322 vector that was digested with EcoRI / SalI and filled in with T4 DNA polymerase, thereby obtaining the recombinant plasmid pSK015 ( figure 2 ).

[0067] Conditions and systems for PCR amplification:

[0068] 1. PCR amplification system

[0069]10×amplification buffer: 5 μL, 4 kinds of dNTP mixture (2.5 mM): 4 μL, NS3-F (20 mM): 0.5 μL, NS3-R (20 mM): 0.5 μL, plasmid template DNA (100 ng / μl): 0.5 μL, Fast Pfu Fly DNA polymerization: 1 μL, add double distilled water to 50 μL;

[0070] 2. PCR amplification conditions:

[0071] 95°C for 5min, 95°C for 30s, 55°C for 30s, 72°C for 3min (return to the second st...

Embodiment 3

[0072] Example 3: Conjugative transfer of Synechococcus sp. UTEX2973 and screening of zygotes

[0073] 1. Take 1 mL of the logarithmic growth phase (OD 730 About 1.0) Synechococcus UTEX2973 culture, centrifuge at 5000 rpm for 5 minutes to collect the cells; wash the cells with fresh BG11 medium, and then resuspend the cells in 100 μL of BG11 medium.

[0074] 2. Cultivate Escherichia coli HB101 strains containing pRL443 plasmid and pRL623 plasmid, and Escherichia coli HB101 containing pSK015 plasmid in LB medium (10g / L peptone, 10g / L sodium chloride, 5g / L yeast extract) Two kinds of bacterial strains of bacterial strain, bacterial strain is cultivated to logarithmic growth phase (OD 600 about 1.0); take 1 mL of Escherichia coli culture, and centrifuge at 5000 rpm for 5 minutes to collect the cells; wash the cells with fresh LB medium, and resuspend the cells in 100 μL LB medium respectively.

[0075] 3. Mix the Escherichia coli HB101 strain containing the pRL443 plasmid and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com