Method for bleaching Birdseye Maple bark

A bird's-eye maple and veneer technology, applied in the field of bleaching, can solve problems such as restricting the development of bird's-eye maple veneer processing, declining product grade quality, and reducing bird's eye clarity, and achieves natural texture and bird's eye clarity maintenance, size Stable, good looking results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Present embodiment provides a kind of bird's-eye maple veneer bleaching method, comprises the following steps:

[0028] S1), the first bleaching

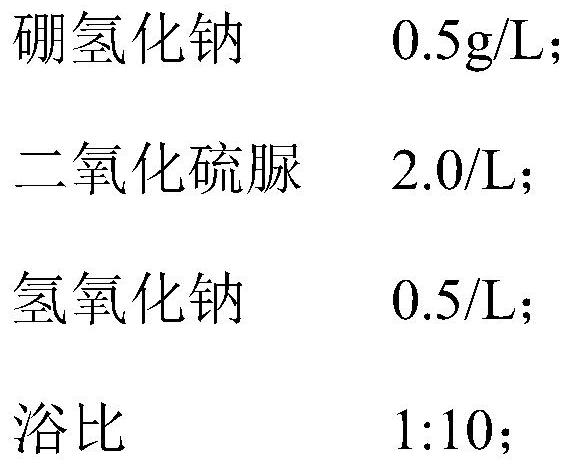

[0029] S101), reduction bleach formula

[0030]

[0031] S102), bleaching process

[0032] Put the bird's eye maple veneer into a 1000ml veneer bleaching box, add 0.5g of sodium hydroxide into the water, add 0.5g of sodium borohydride into a small container, stir evenly and dissolve completely, then inject into the veneer bleaching box, and then add sulfur dioxide Inject urea 2.0 into the veneer bleaching frame and stir evenly. A large number of bubbles are formed when it is just opened, and the reaction is violent. Slowly raise the temperature to 60°C and keep it warm for 2 hours.

[0033] S2), the second bleaching

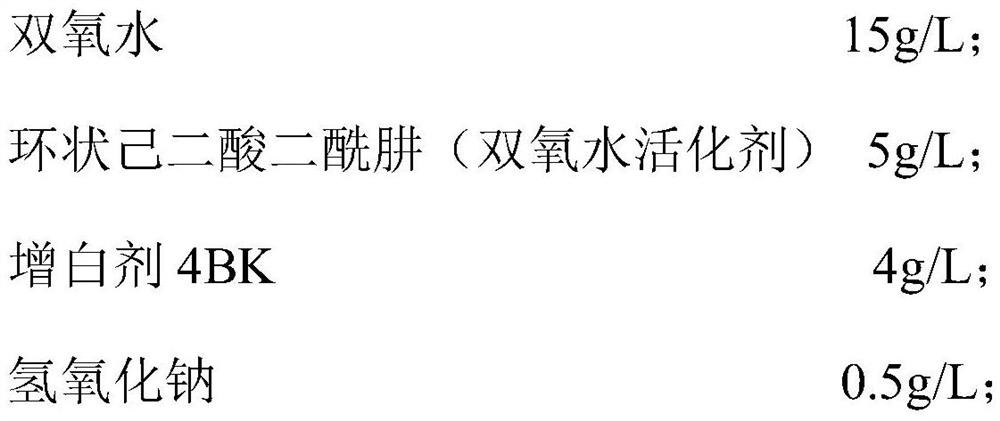

[0034] S201), oxidation bleaching formula

[0035]

[0036] S202), bleaching process

[0037] Add 5g of cyclic adipic dihydrazide into a small container, pour hot water at 60°C to dissolve, stir to di...

Embodiment 2

[0039] Present embodiment provides a kind of bird's-eye maple veneer bleaching method, comprises the following steps:

[0040] S1), the first bleaching

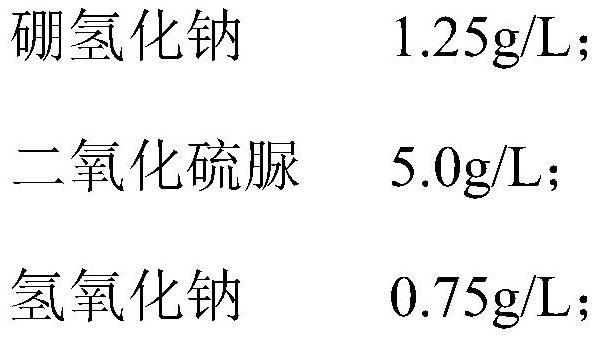

[0041] S101), reduction bleach formula

[0042]

[0043]

[0044] S102), bleaching process

[0045] Put the bird's eye maple veneer into a 1000ml veneer bleaching box, add 0.75g of sodium hydroxide into the water, add 1.25g of sodium borohydride into a small container, stir evenly and completely dissolve, then inject into the veneer bleaching box, and then add sulfur dioxide Inject 5 g of urea into the veneer bleaching frame, stir evenly, a large number of bubbles are formed when it is just opened, and the reaction is violent, slowly raise the temperature to 60 ° C, and keep it warm for 2 hours.

[0046] S2), the second bleaching

[0047] S201), oxidation bleaching formula

[0048]

[0049] S202), bleaching process

[0050] Add 7.5g of cyclic adipate dihydrazide into a small container, inject hot water at 60°C t...

Embodiment 3

[0052] Present embodiment provides a kind of bird's-eye maple veneer bleaching method, comprises the following steps:

[0053]S1), the first bleaching

[0054] S101), reduction bleach formula

[0055]

[0056]

[0057] S102), bleaching process

[0058] Put the bird's eye maple veneer into a 1000ml veneer bleaching box, add 1g of sodium hydroxide to the water, add 2g of sodium borohydride into a small container, stir evenly and completely dissolve, then pour into the veneer bleaching box, and then add 8g of thiourea dioxide Pour into the veneer bleaching box, stir evenly, when it is just opened, a large number of bubbles are formed, the reaction is violent, slowly raise the temperature to 60 ° C, and keep it warm for 2 hours.

[0059] S2), the second bleaching

[0060] S201), oxidation bleaching formula

[0061]

[0062] S202), bleaching process

[0063] Add 10g of cyclic adipate dihydrazide into a small container, inject hot water at 60°C to dissolve, stir to dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com