Crop straw electric vehicle

A technology for crop straws and electric vehicles, applied in the field of electric vehicles, can solve the problems of inability to drive long distances, difficult to restore electric power, and low actual utilization rate of electric vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

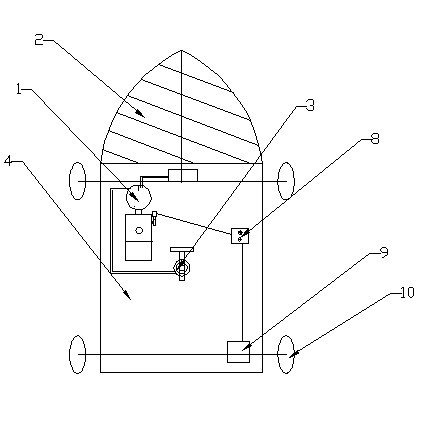

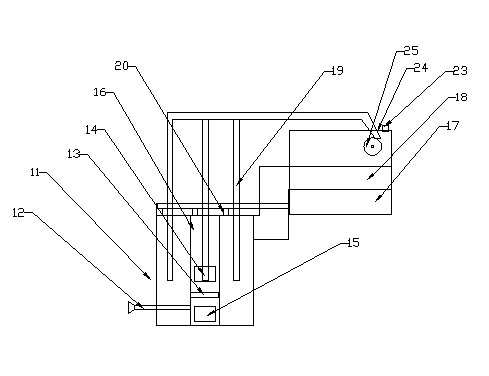

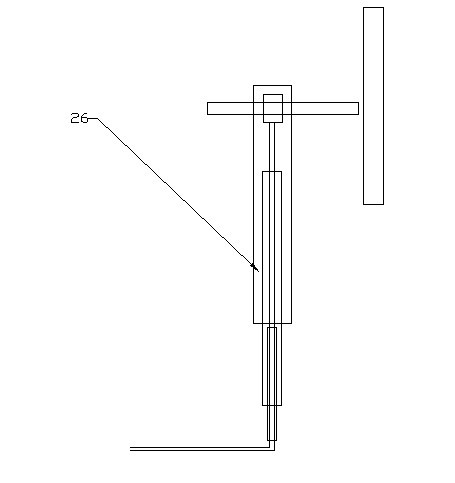

[0010] The crop straw electric vehicle includes a chassis 4, a generator 7, a storage battery 8, an electric motor 9, and driving wheels 10, mainly including a water vapor internal pressure generating furnace 1, a furnace body 11, an air inlet 12, a fire grate 13, a charging furnace door 14, The slagging furnace door 15, the combustion chamber 16, and the water vapor cylinder 5 are composed of the combustion chamber 16, which is in the middle of the water vapor internal pressure generating furnace 1. The front of the combustion chamber 16 is the charging furnace door 14, and the bottom is the fire grate 13. Below is the slagging furnace door 15 and the air inlet 12. The combustion chamber 16 is connected to the chimney water tank 17 through the chimney 18. There is a water filling port 23 on the chimney water tank 17. The combustion chamber 16 is surrounded by three parts that are equally divided into three parts and do not communicate with each other. Water vapor cylinder 5, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com