Opening and closing type induction heating device

An induction heating device and an opening and closing technology, which are applied in the field of opening and closing induction heating devices, can solve the problem that the induction head cannot meet the induction heat treatment of special large-scale ring parts and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

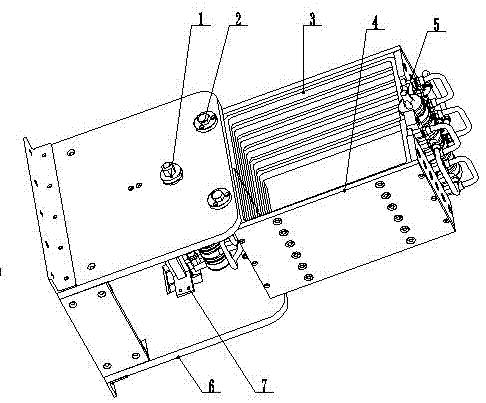

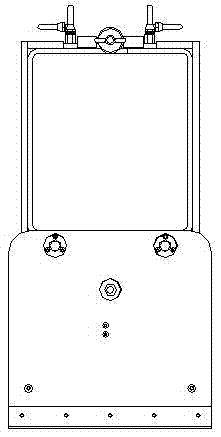

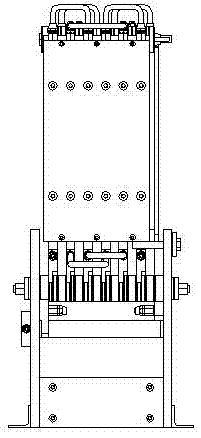

[0011] like figure 1 As shown, a split-type induction heating device includes an inductor and a connecting seat, the inductor includes a connecting plate 4, and the connecting plate 4 is connected by connecting bolts 5 to form a workpiece processing area; the inner surface of the connecting plate 4 is provided with an induction coil 3, and the connecting plate 4 is connected to the connecting seat 6 through the rotating shaft 1, and the connecting row 7 is fixed on the connecting seat 6; an anti-rotation rod 2 is provided at the intersection of the connecting seat 6 and the connecting plate 4, and the anti-rotating rod 2 passes through the connecting seat 6 and is inserted on the connecting plate 4 sides. figure 2 , image 3 and Figure 4 aided understanding figure 1 .

[0012] The present invention loosens the connecting bolt 5 on the top of the inductor, unscrews the anti-rotation rod 2, and the induction coil 3 can be rotated around the rotating shaft 1 on the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com