Induction cooker for heating aluminum pot

A technology of induction cooker and aluminum pan, applied in induction heating, induction heating control, electric/magnetic/electromagnetic heating, etc., can solve the problems of inability to heat the aluminum pan, the power tube of the induction cooker is overloaded with current, and the calorific value is small. Effects of large eddy currents and equivalent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

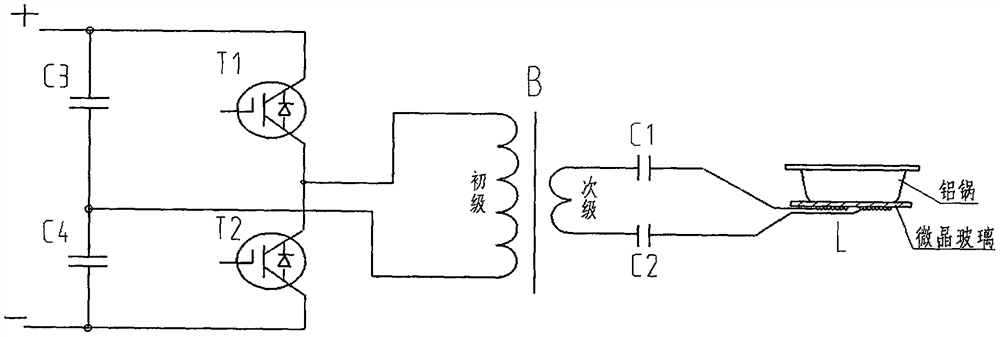

[0016] figure 2 For the specific implementation legend.

[0017] in figure 2 Among them, C3 and C4 form the power supply voltage divider capacitor. T1 and T2 are power tubes.

[0018] The connection point of C3 and C4 is a contact point of the power output of the induction cooker, and the connection point of T1 and T2 is the other contact point of the power output of the induction cooker. These two contacts are respectively connected to the primary of the power transformer.

[0019] The secondary coil of the power transformer is respectively connected in series with resonant capacitors C1 and C2 and then connected to the induction coil of the induction cooker. There is glass-ceramic on the induction coil of the induction cooker, and an aluminum pan is placed on the glass-ceramic.

[0020] Power on the induction cooker to work, the aluminum pan heats up normally, and the induction cooker works completely normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com