A cooling improved heat treatment equipment for alloy steel strip and heat treatment process for alloy steel strip

A heat treatment equipment and improved technology, applied in heat treatment equipment, heat treatment furnace, heat treatment process control and other directions, can solve the problems of less comprehensive equipment and less cooling control, and achieve a wide range of applications and a large cooling rate controllable range , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

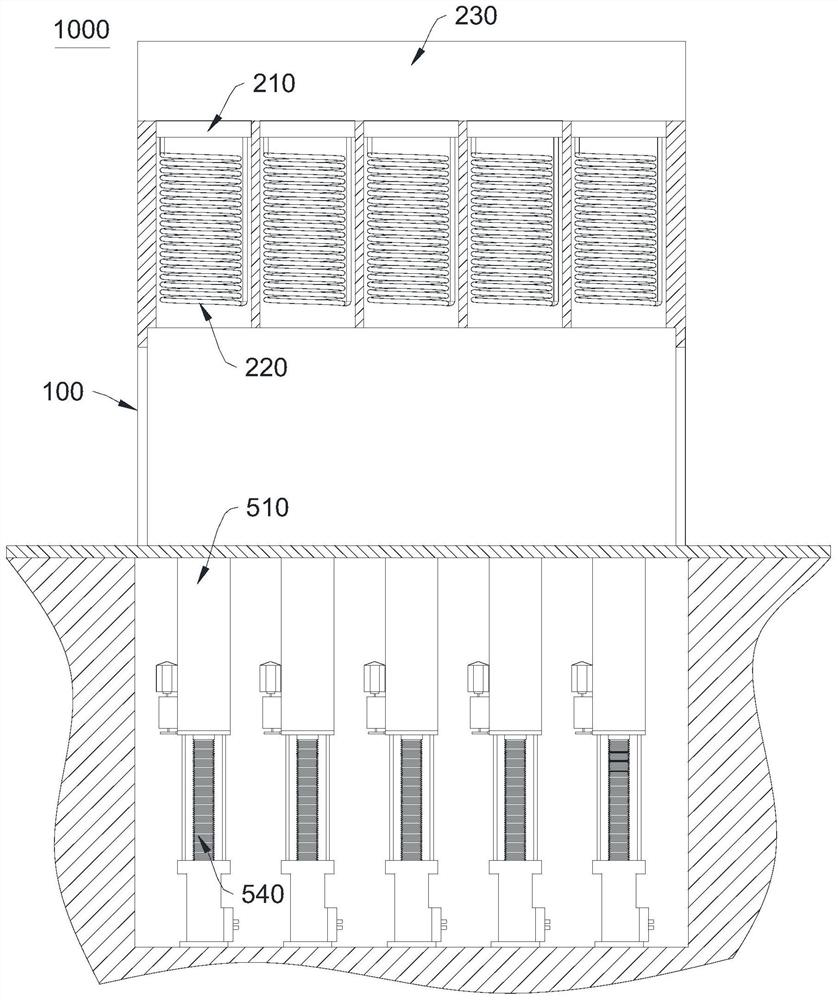

[0048] Please refer to Figure 1~7 , this embodiment provides an improved cooling heat treatment equipment 1000 for alloy steel strips. The improved cooling heat treatment equipment 1000 includes: a heat treatment chamber 100, a heat treatment assembly and a cooling assembly.

[0049] The heat treatment assembly includes a first base 210 , an induction coil 220 and a first lifting assembly 230 . The induction coil 220 is fixedly installed on the first base 210 and extends toward the heat treatment chamber 100 . The first base 210 is driven by the first lifting assembly 230 so that the induction coil 220 can extend into the heat treatment chamber 100 to cover the steel coil.

[0050] The cooling assembly includes a first air duct 310 , a second air duct 320 , a second base 400 and a second lifting assembly 500 . Wherein, both the first air duct 310 and the second air duct 320 are in a spiral shape, and the central axes of the first air duct 310 and the second air duct 320 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com