lathe

A lathe and bed technology, applied in the field of mechanical processing equipment, can solve the problems of inconvenient use, inability to adapt to the processing of parts with different diameters, and the inability to adjust the inner diameter, etc., and achieve the effects of improving processing accuracy, simple structure, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

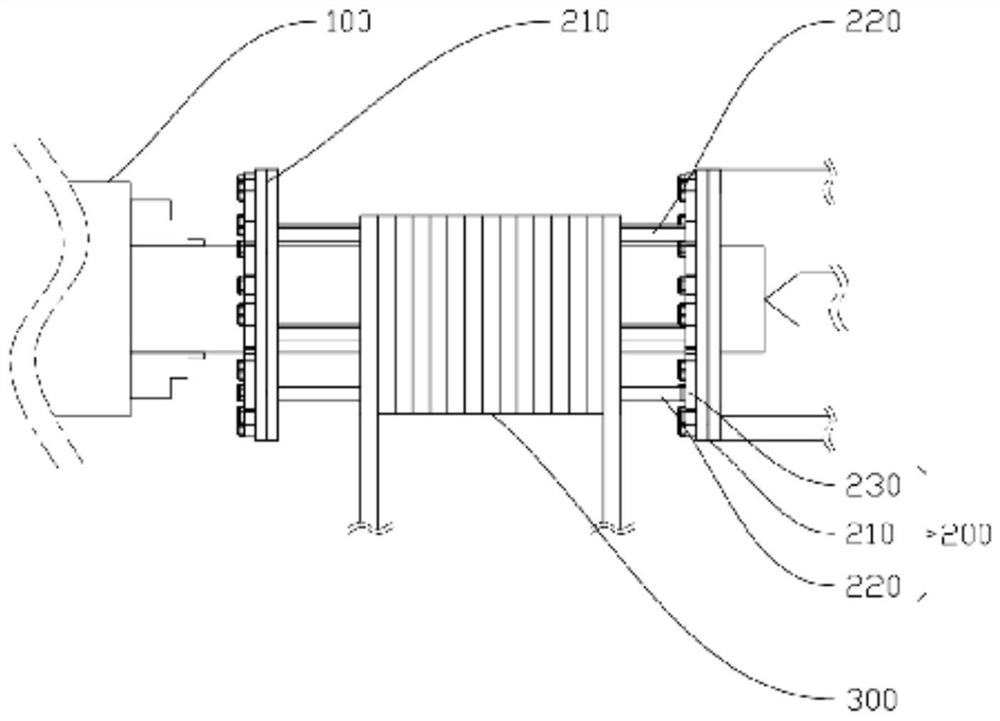

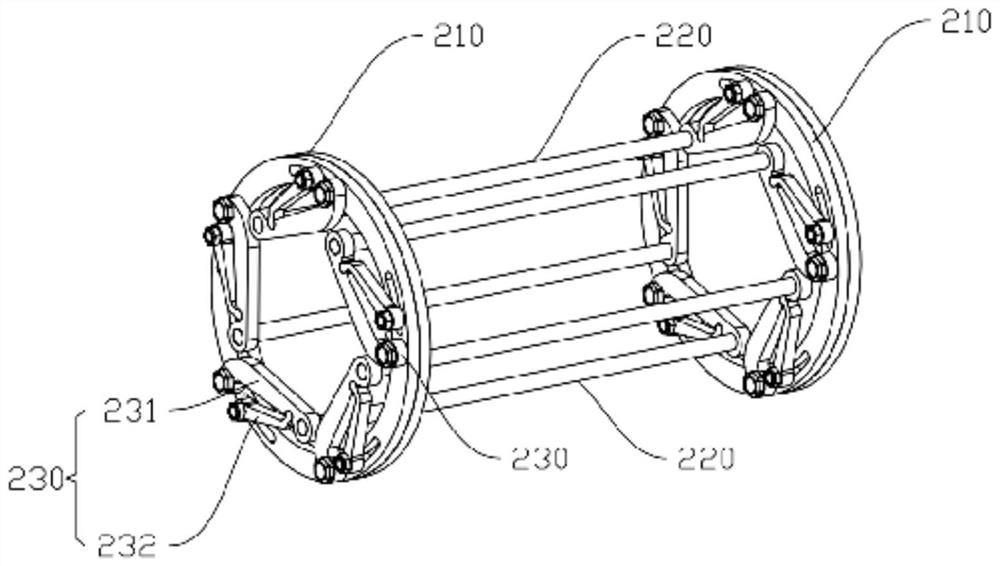

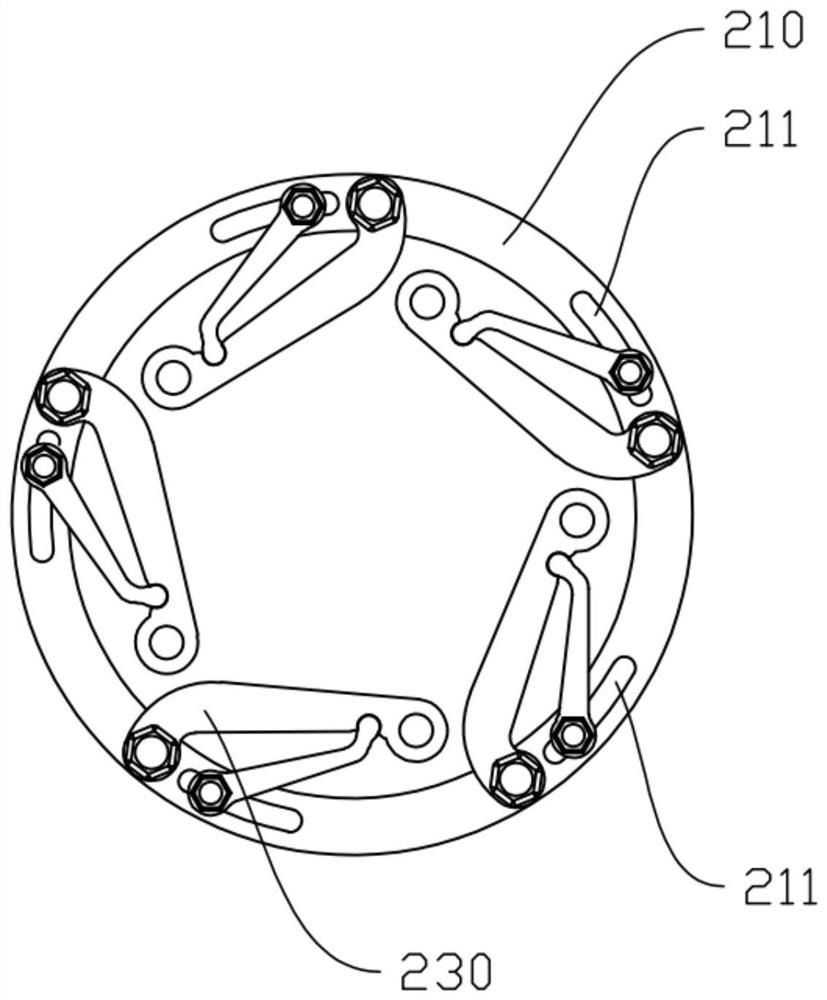

[0020] refer to figure 1 , the lathe according to the embodiment of the present invention includes a bed, a headstock 100, a slide box, a tailstock and a tool rest, and also includes an induction heating coil 300, a coil support 200 and a heating electric control box, wherein the coil support 200 and the tool rest The fixed mechanical connection can move together with the tool holder under the drive of the sliding crate. The heating electric control box is arranged on the bed, and the induction heating coil 300 is electrically connected with the heating electric control box. The induction heating coil 300 is made of a flexible cable. The induction heating coil 300 is wound on the coil support 200. The induction heating coil 300 is erected outside the measuring surface of the workpiece to be processed through the coil support 200 to heat the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com