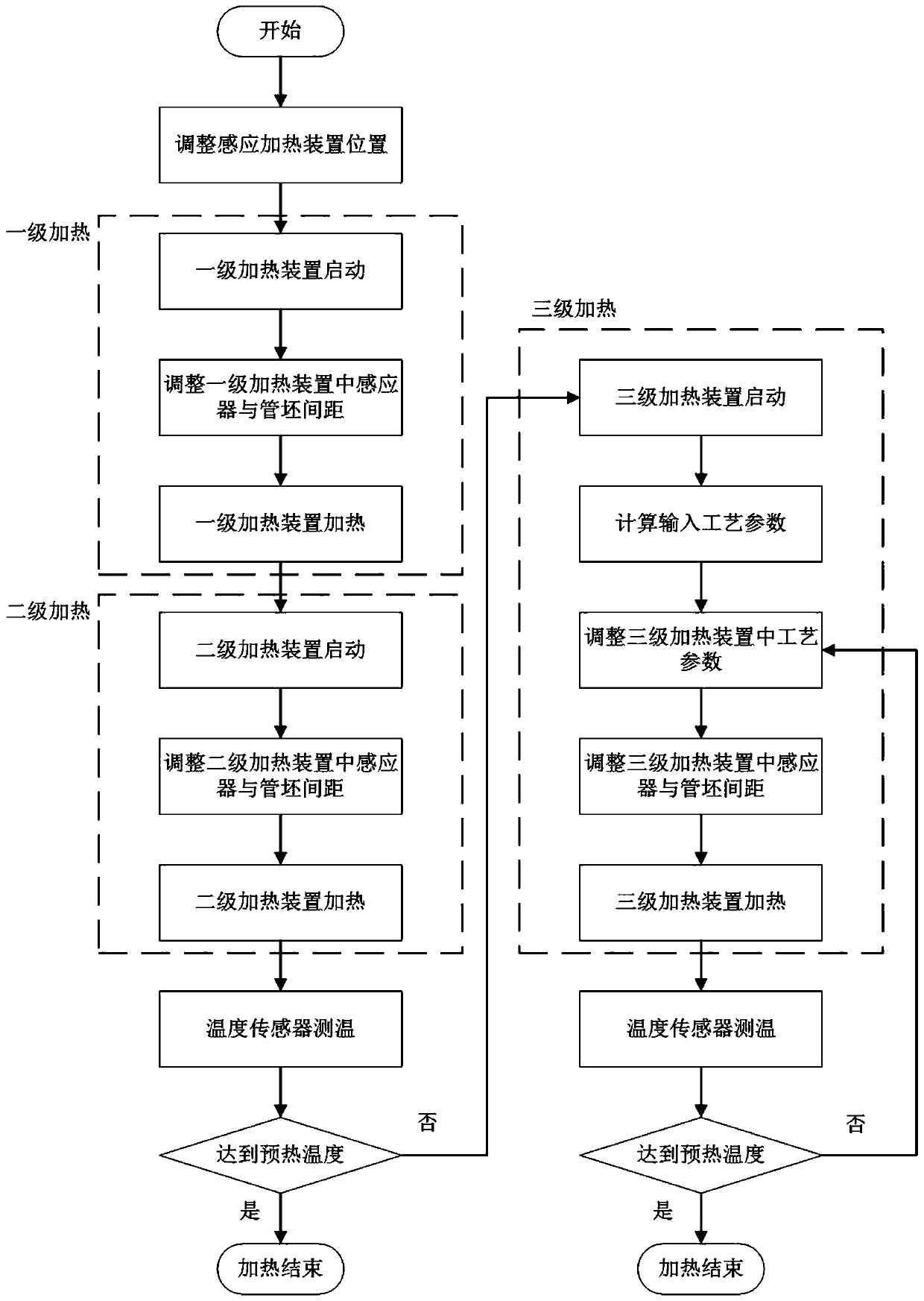

A kind of induction heating device and method for welding preheating of thick-walled oil pipe

An induction heating device and heating device technology, applied in the field of heat treatment, can solve problems such as low heating efficiency, high energy consumption, and large pollution, and achieve the effects of improving work efficiency, ensuring uniform preheating, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

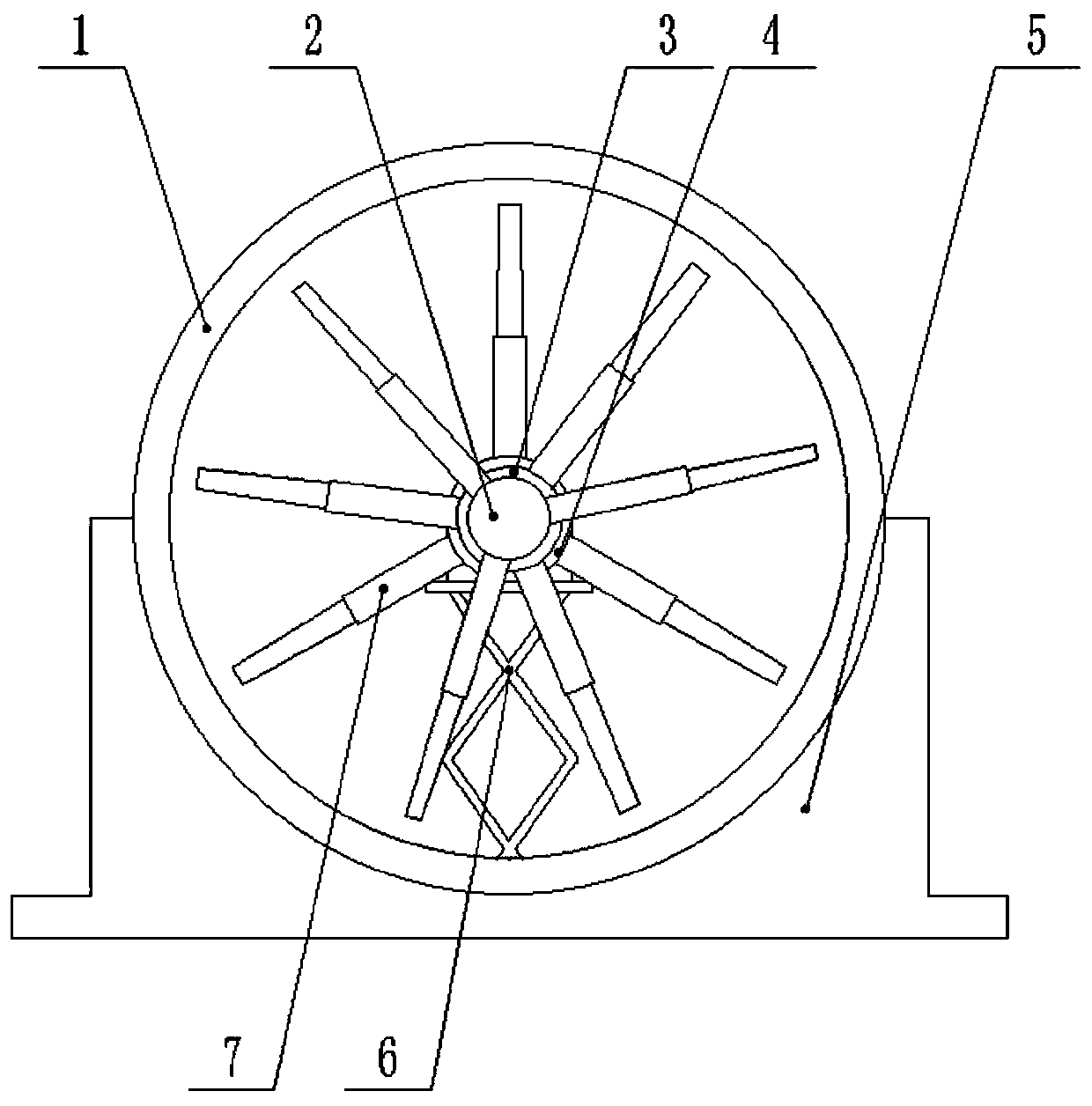

[0038] Exemplary embodiments, features, and aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

[0039] Specifically, the present invention provides an induction heating device for welding preheating of thick-walled oil pipes, as shown in Fig. 2 to Figure 4As shown, it includes a control assembly, a multi-stage heating device, a support base 5, a bracket 9, a lifting device 6, a plurality of temperature sensors 8, a transmission device, a driving motor, a linear push rod 11 and a rear mounting plate 12.

[0040] The tube blank 1 to be heated is fixed on the support base, and a bracket 9 is arranged outside the multi-stage heating device. The multi-stage heating device is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com