A kind of fish starch modified polylactic acid monofilament and preparation method thereof

A technology of starch modification and polylactic acid, which is applied in the manufacture of rayon, single-component polyester rayon, melt spinning, etc., and can solve the problems that the mechanical properties of polylactic acid fibers cannot well meet the needs of practical applications. , to achieve the effects of improving fluidity and spinnability, increasing breaking strength and knot strength, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

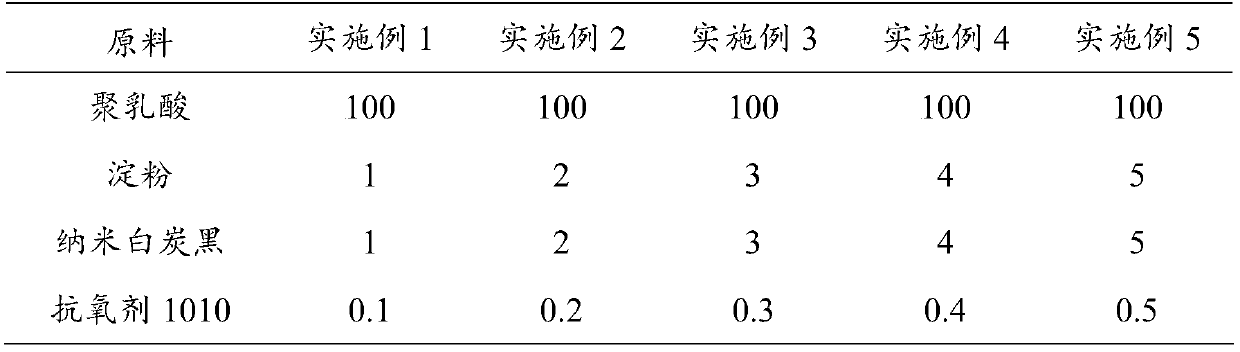

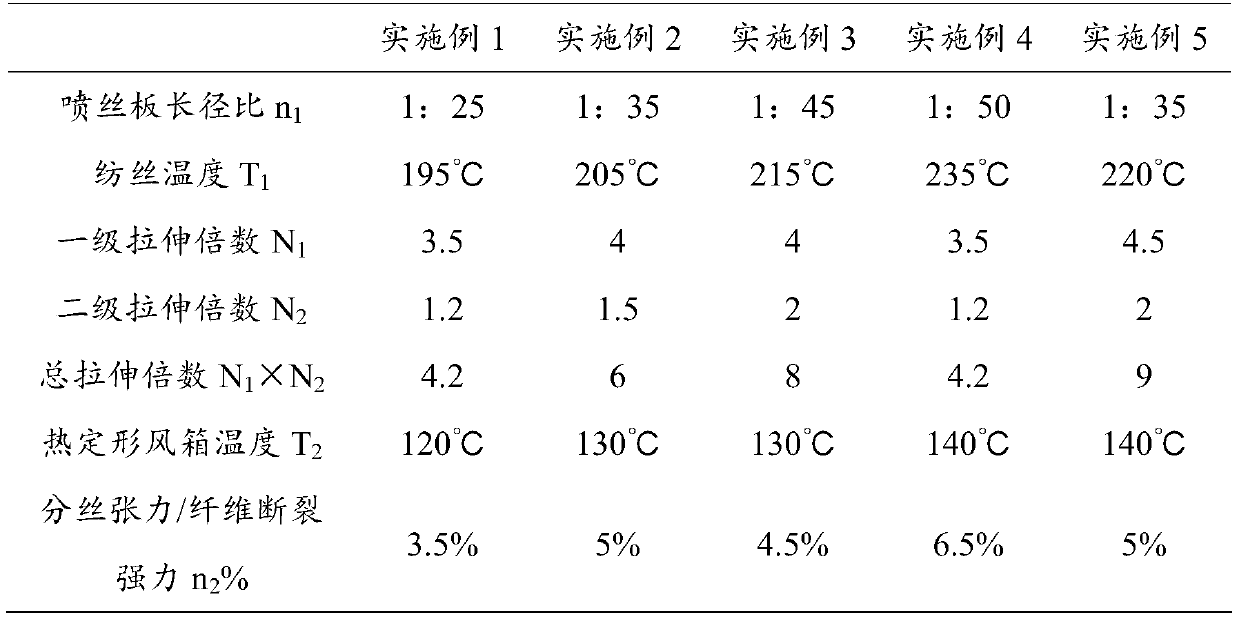

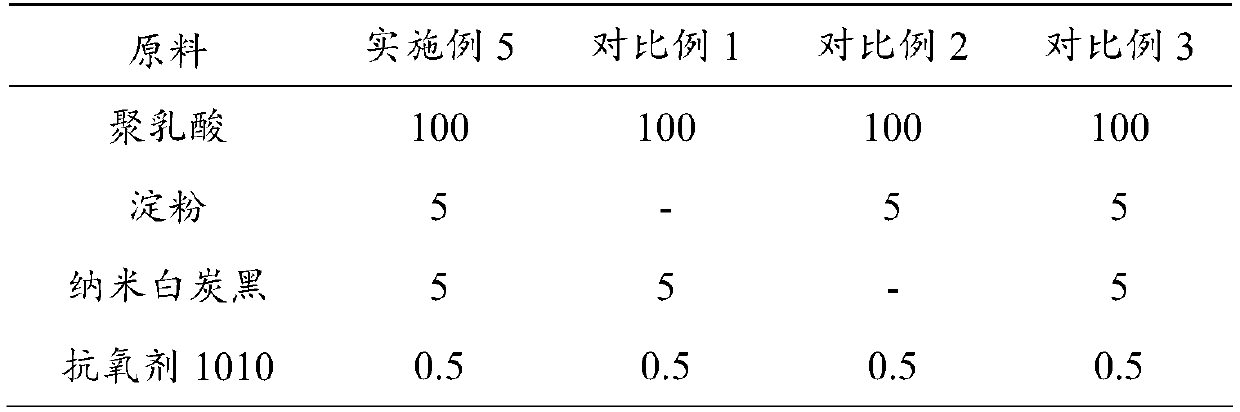

[0033] Examples 1-5 are the preparation of the starch-modified polylactic acid monofilament of the present invention. The raw materials and their parts by weight are shown in Table 1, the manufacturing method is the same, and the corresponding parameters in the process are shown in Table 2. Concrete preparation steps are as follows:

[0034] (a) Premix the polylactic acid (number average molecular weight: 150000), starch, nano-silica and antioxidant 1010 of the formulation amount and pour it into the kneader, and carry out high-speed kneading at a speed of 500r / min-750r / min. Knead for 30min-60min, when the temperature of the mixture in the kneader (kneading pot) rises to 70°C, the material can be discharged to obtain a composite polylactic acid modified material;

[0035] (b) The polylactic acid modified material is extruded and granulated by a twin-screw extruder. The residence time of the polylactic acid modified material in the twin-screw extruder is 5-7 minutes, and the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com