Arm used for variable nozzle mechanism, variable nozzle mechanism, and turbocharger

A variable, nozzle technology, applied in the direction of machines/engines, mechanical equipment, combustion engines, etc., to achieve the effect of inhibiting wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

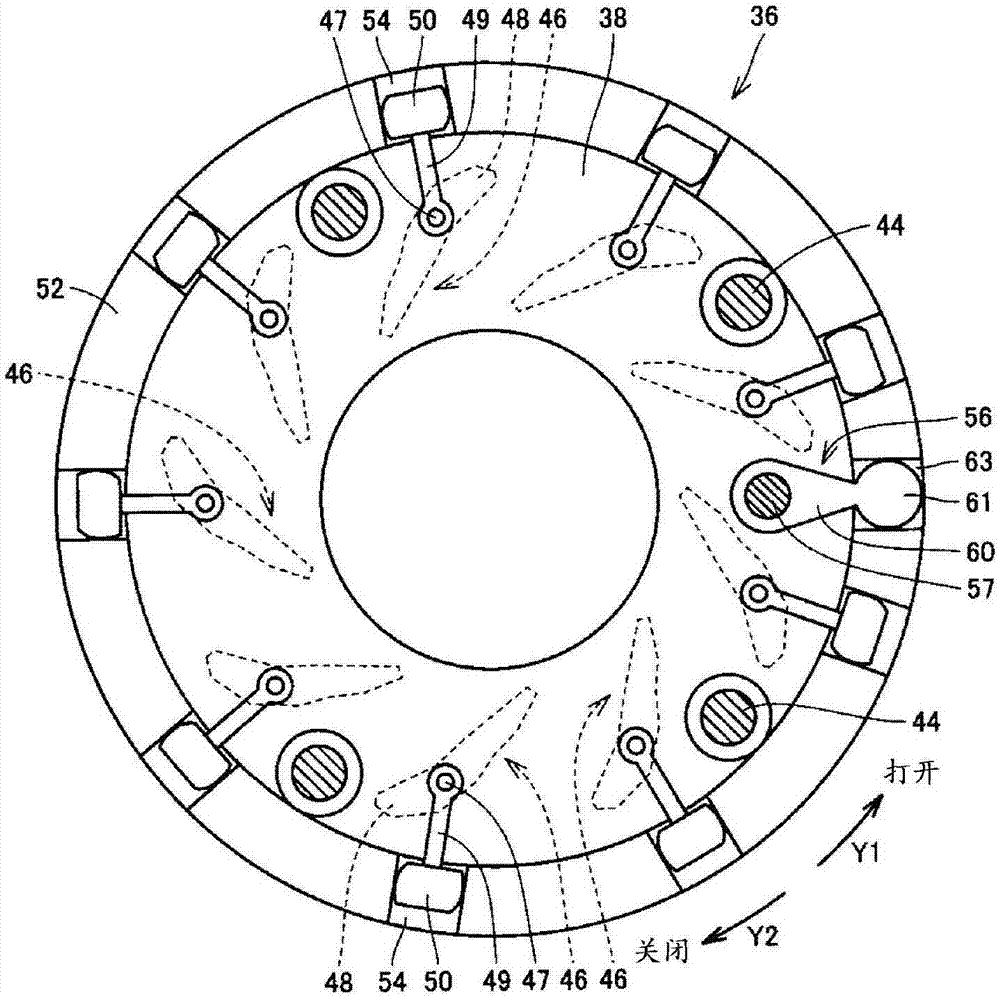

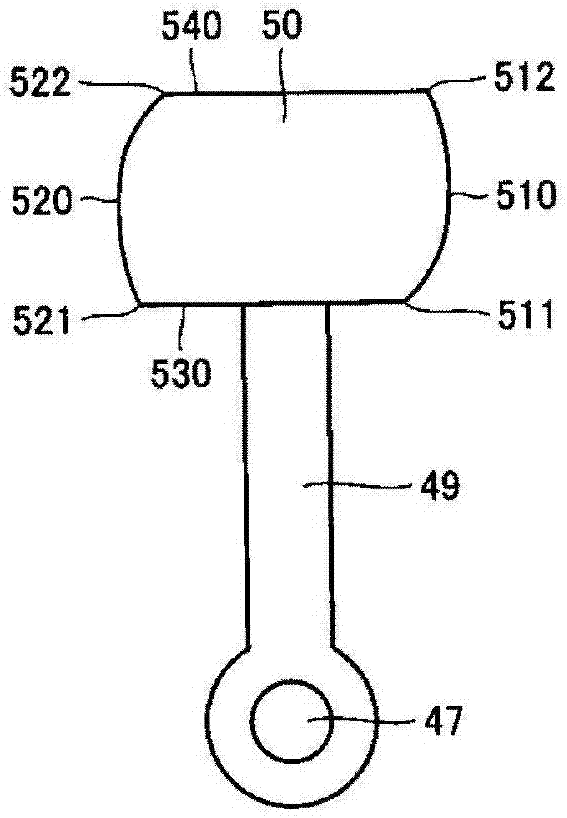

[0024] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. It should be noted that the same reference numerals are attached to the same or corresponding parts in the drawings, and the description thereof will not be repeated.

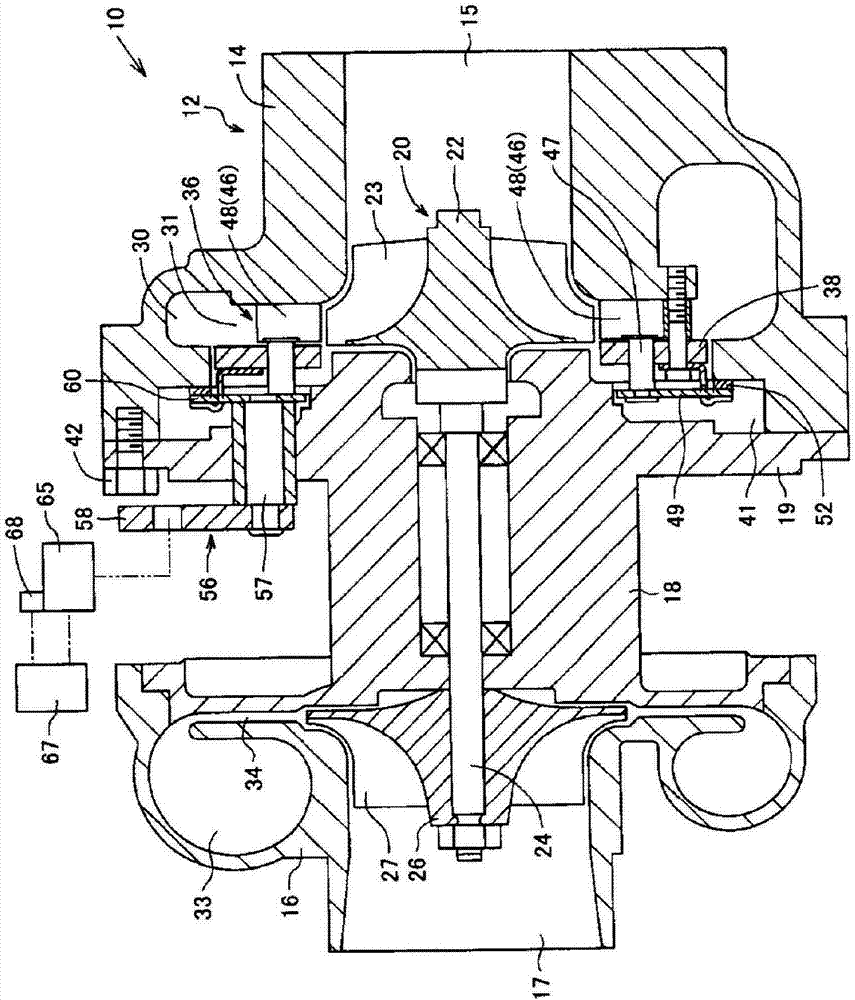

[0025] First, the overall structure of the variable nozzle turbocharger 10 will be described. In addition, in this embodiment, the variable nozzle turbocharger 10 mounted in the internal combustion engine mounted in a vehicle is demonstrated as an example. figure 1 is a sectional view of the variable nozzle turbocharger 10 along the rotation axis.

[0026] Such as figure 1 As shown, the variable nozzle turbocharger 10 includes a rotor 20 . The rotor 20 is rotatably accommodated in the rotor housing 12 . The rotor housing 12 has three housings: a turbine housing 14 , a compressor housing 16 , and a center housing 18 . The center housing 18 connects the turbine housing 14 and the compressor ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com