Hydraulic U-type channel waterpower cycle power generation system

A power generation system and cycle power generation technology, applied in hydropower, engine components, machines/engines, etc., can solve problems such as gaps, and achieve quick results, easy structure, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

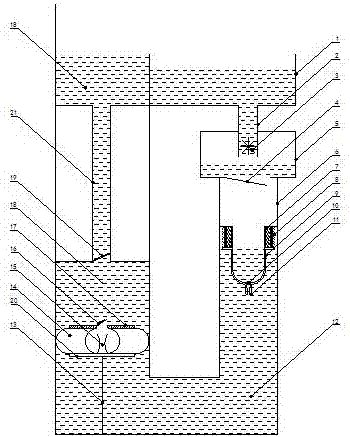

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] In the cycle power generation system of the present invention, the U-shaped track is a special-shaped U-shaped track with unequal crossing diameters on both sides.

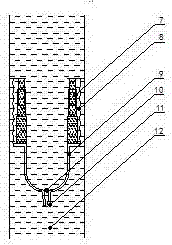

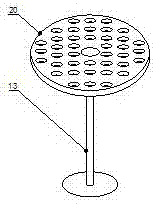

[0024] In the cycle power generation system of the present invention, the small diameter side of the U-shaped channel is the water inlet, and the structure is: the top is the diversion pipe 2, the diversion pipe 2 is provided with the power storage pool 5, the power storage pool 5 is the force application area 6, and the force application area 6 The small piston 9 is placed below the small piston 9, and the liquid storage chamber 12 connected to the large piston is located below the small piston 9; the large diameter side of the U-shaped channel is the water outlet, and the water accumulation area 18 in the channel is an I-shaped structure. The upper part is the drainage area 18, and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com