Improved high-pressure needle valve and quick replacement method thereof

A high-pressure needle and improved technology, which is applied in the direction of valve lift, valve details, valve device, etc., can solve problems such as waste, and achieve the effects of avoiding waste, saving production costs, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

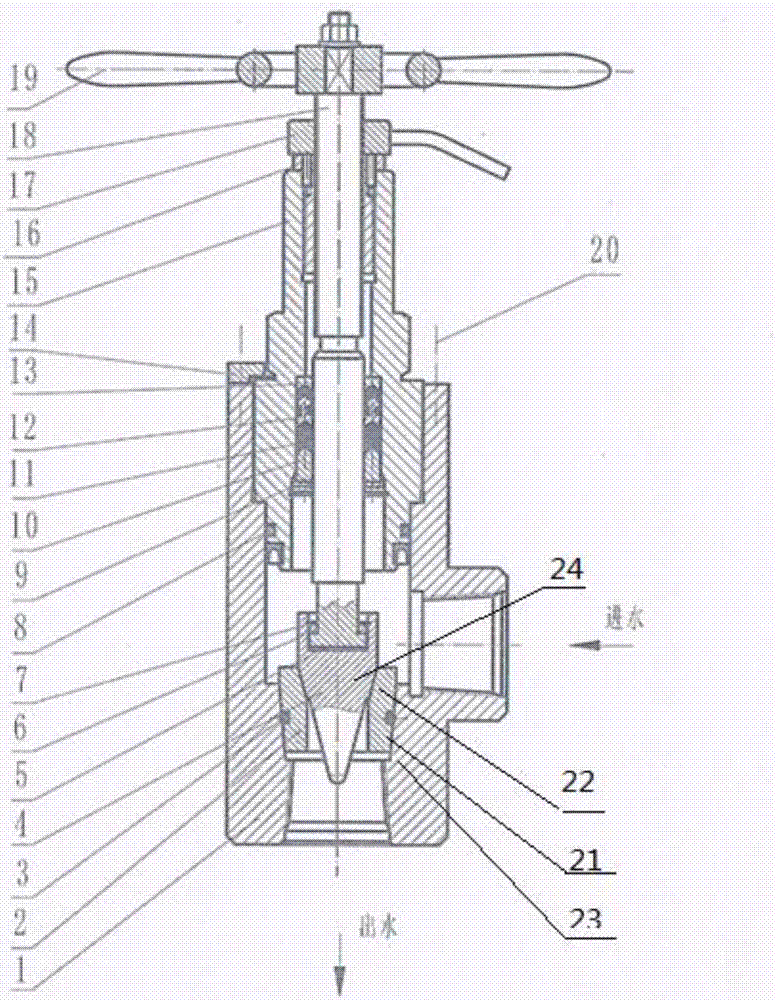

[0032] An improved high-pressure needle valve, including a valve body 1, a valve seat 2, a valve core 4, a valve cover 15, a valve stem 18 and a hand wheel 19, and the valve body 1 is provided with a valve seat 2, a valve core 4 and a valve stem 18 , the valve body 1 is fastened with the valve cover 15; the valve core 4 is provided with an inner sealing cone 24, and the valve seat 2 is provided with an outer sealing cone 21 and an inner sealing cone 22, the valve body 1 is provided with an outer sealing cone 23, the inner sealing cone 24 and the inner sealing cone 22 are bonded to form an inner line seal, and the outer sealing cone 21 and the outer sealing cone 23 form an outer line seal . The spool 4 is provided with a groove and a retaining ring 7, the T-shaped end of one end of the valve stem 18 extends into the groove of the spool 4, the retaining ring 7 locks the T-shaped end, the retaining ring 7 and the T-shaped An adjustment pad 6 is provided between the blocks. A se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com