A clamping force test tool for isolating switch

A technology for testing tooling and isolating switches, applied to measuring devices, force/torque/work measuring instruments, instruments, etc., can solve problems such as unrealistic clamping force, large measurement errors, and inability to fix the second extrusion part, etc. Achieve the effect of reducing measurement error and ensuring assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

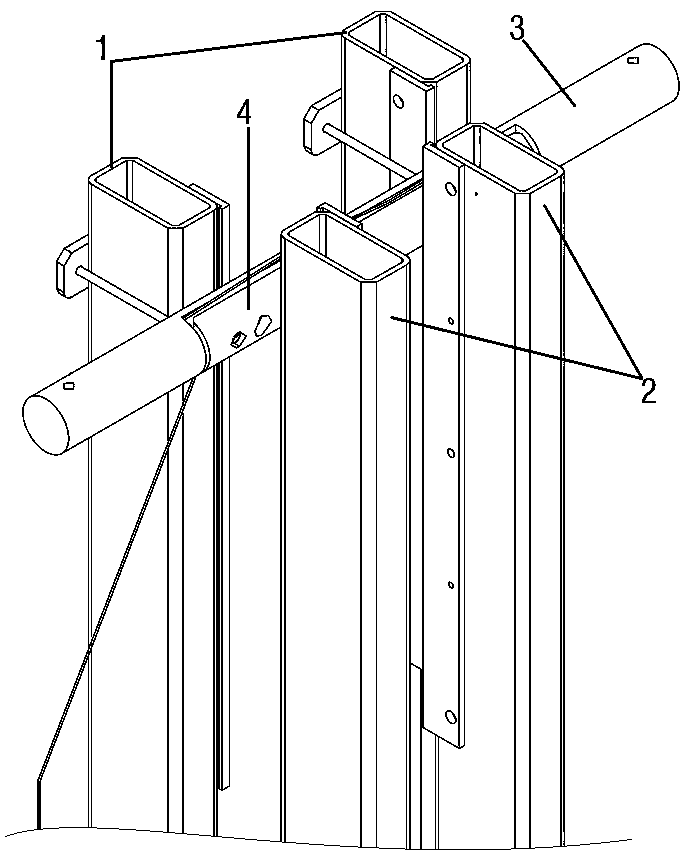

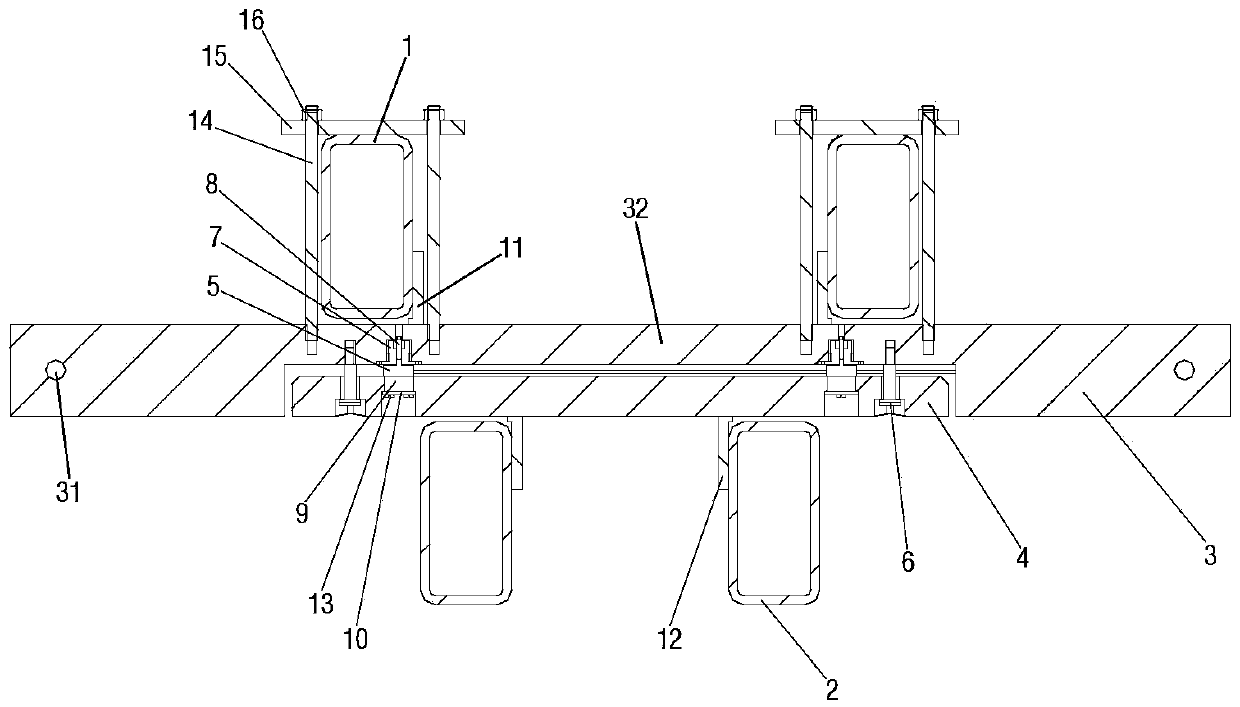

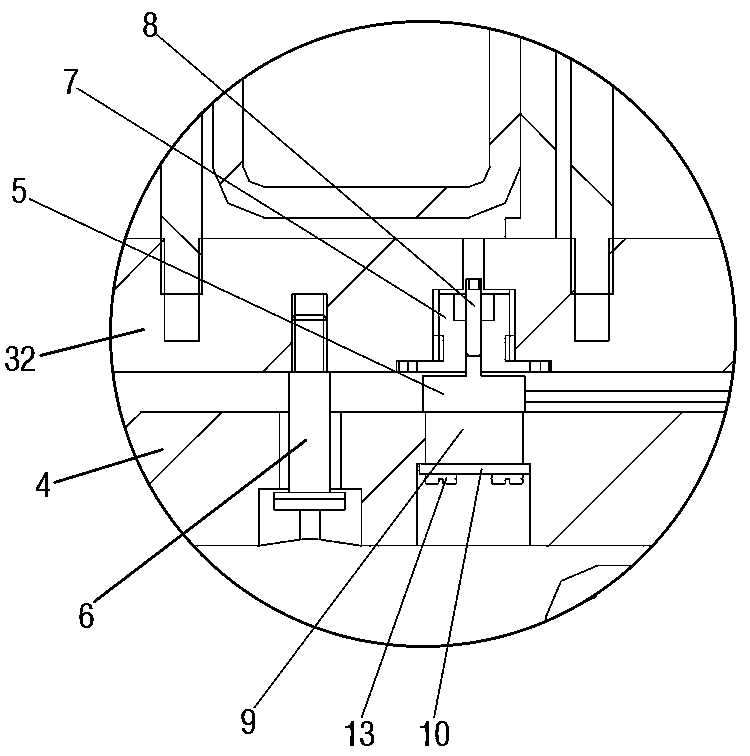

[0039] Embodiment 1 of the clamping force test tooling for the isolating switch is as Figure 1~Figure 17 As shown, the test tooling is made of an aluminum rod which is turned and then cut by wire cutting. The hardness of the aluminum rod is similar to that of the real static contact made of red copper, and it is not easy to damage the moving contact, so it can better simulate The working condition of the real static contact, and the price is relatively cheap. The cut aluminum bar includes a column body 3 and a second extruded portion 4 with an arcuate cross section, and the column body 3 includes a first extruded portion 32 with an arcuate cross section and cylinders located at both ends of the first extruded portion 32 ( That is, the limiting cylinder 33). The bowstring parts of the first extruding part 32 and the second extruding part 4 are arranged oppositely, and a pressure sensor 5 is arranged between them. The pressure sensor 5 has a first force-bearing surface and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com