A kind of anti-rust method of stator and rotor iron core

A stator-rotor and iron-core technology, which is applied in the anti-rust field of stator-rotor iron cores, can solve problems such as easy corrosion on the surface of the iron core, difficult cleaning, and poor operability, so as to reduce operational difficulty, improve operability, and avoid cleaning work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The core of the present invention is to provide an anti-rust method for the stator and rotor cores to improve the operability of the anti-rust treatment method for the rotor cores.

[0031] In order to enable those skilled in the art to better understand the technical solutions provided by the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

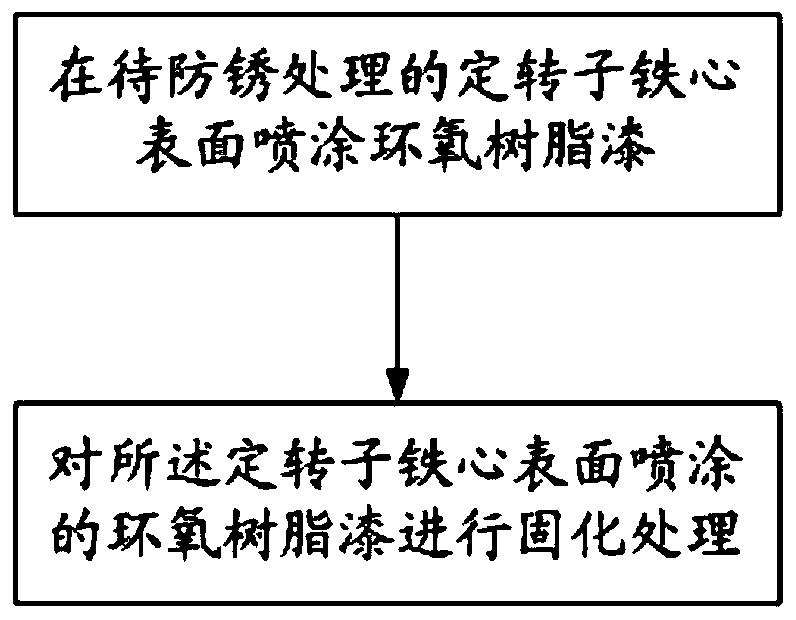

[0032] Such as figure 1 As shown, an anti-rust method for a stator and rotor core provided by an embodiment of the present invention includes the steps:

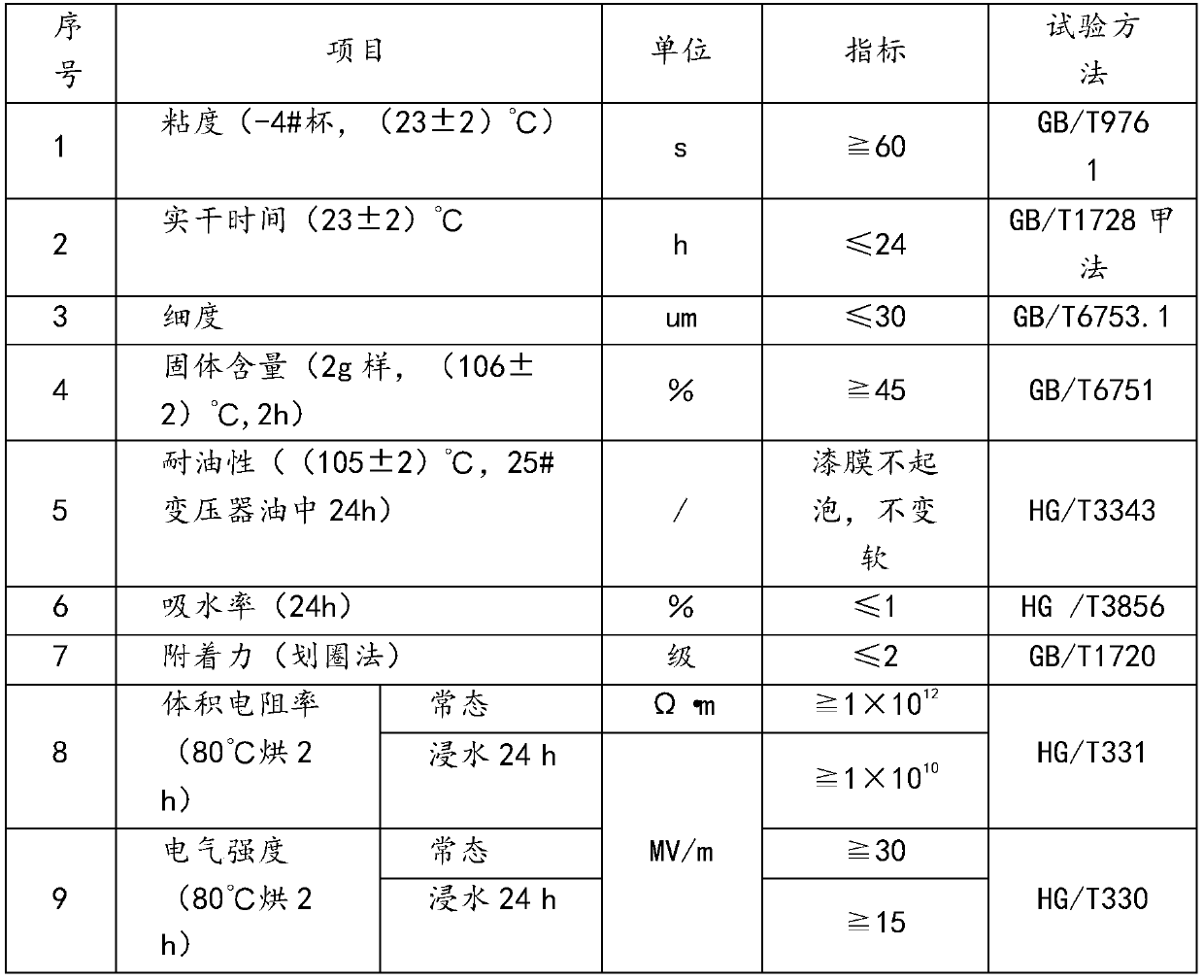

[0033] Step 100: Spray epoxy paint on the surface of the stator and rotor cores to be rust-proofed; what needs to be explained here is that the dipping paint itself should be the same type of paint as the epoxy paint, or it has been tested and verified that it will not be the same as the dipping paint Paint that reacts chemically.

[0034] Step 200: curing the epoxy paint sprayed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com