Flexible PCB reinforcing fitting method

A printed circuit board and reinforcement technology, applied in the direction of printed circuit, printed circuit manufacturing, printed circuit components, etc., can solve the problems of poor flatness, affecting product quality, and the inability of the reinforcement 4 to fit closely, and achieve a tight fit. The effect of combining and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

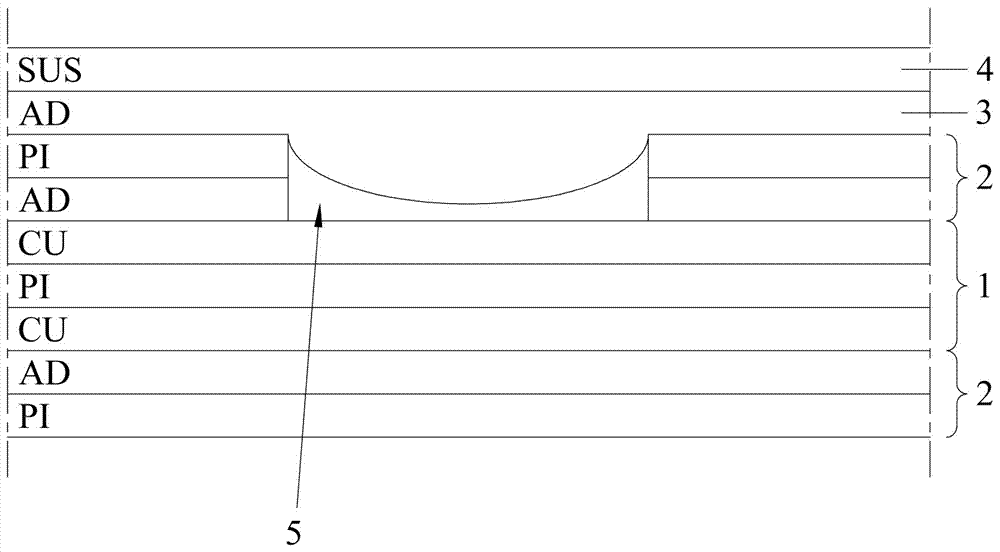

[0013] Embodiment one: see attached figure 2 As shown, the flexible printed circuit board includes a copper foil base material 1, two layers of adhesive protection layers 2 arranged on both sides of the copper foil base material 1, and the adhesive protection layer 2 on the upper surface of the copper foil base material 1 is provided with The glue opening 5 is used for laminating and reinforcing 4 .

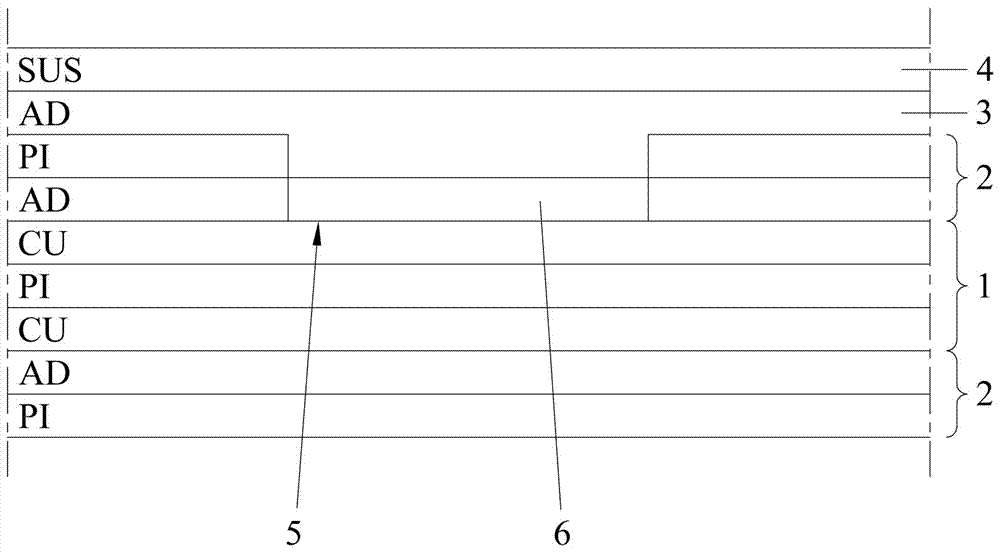

[0014] The method of attaching the reinforcement 4 to the flexible printed circuit is as follows: firstly fill at least part of the adhesive retaining opening 5 to form a filling layer 6 to reduce the depth of the adhesive retaining opening 5, and then coat the adhesive retaining layer 2 Strong glue 3 and fit reinforcement 4. Specifically, when copper is plated at the position of the plastic opening 5 , a selective plating process is added to fill the plastic opening 5 , so that the filling layer 6 formed in the plastic opening 5 is a copper layer. Usually, the thickness of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com