Pre-emulsified powder syrup of hydrophobic and oleophobic powder, preparation and application thereof

A hydrophobic and oleophobic, pre-emulsification technology, used in cosmetic preparations, cosmetics, cosmetics and other directions, can solve the problems of unstable dispersion slurry, no report of hydrophobic and oleophobic powder to prepare oil dispersion slurry, and large equipment loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

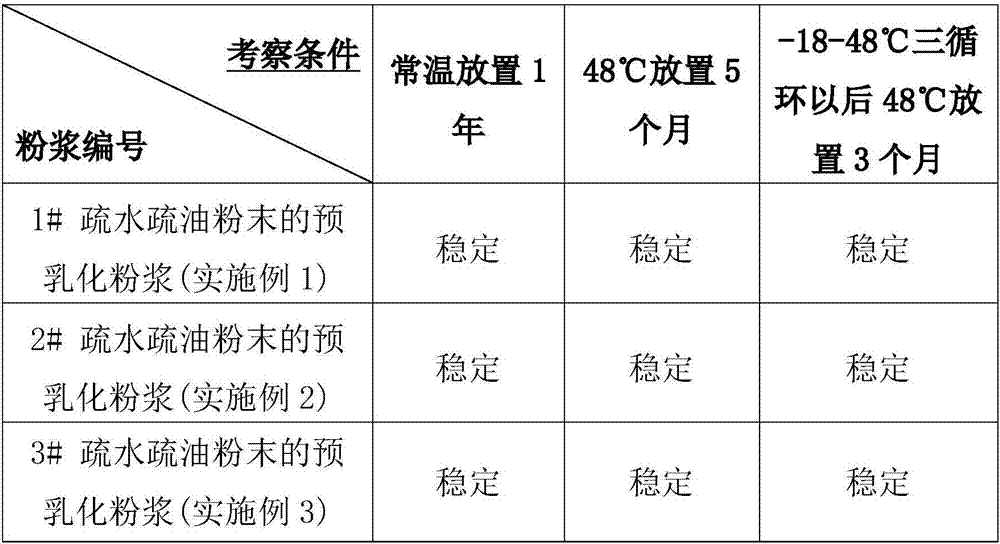

Embodiment 1

[0087] The formula (by weight) of the pre-emulsified slurry of the hydrophobic and oleophobic powder in this example is shown in Table 5.

[0088] The formula composition of the pre-emulsified slurry of the hydrophobic and oleophobic powder of table 5

[0089]

[0090]

[0091] Preparation Process:

[0092] 1. Weigh the raw materials of phase A in a beaker in turn, heat at 80°C until the raw materials are completely melted, then stop heating and stir evenly;

[0093] 2. Add the raw materials of phase B to phase A in turn, stir (380-400 rpm) for 8-10 minutes, and then homogenize (10000-20000 rpm) for 5 minutes to disperse the powder evenly;

[0094] 3. Under rapid stirring (400-500 rpm), slowly add phase C to phase AB to make the emulsification complete. High-speed homogenization (10000 rpm) until the material body is uniform and fine;

[0095] 4. Use a three-roll machine to grind 3 to 4 times to get "1# pre-emulsified slurry of hydrophobic and oleophobic powder".

Embodiment 2

[0097] The formula (by weight) of the pre-emulsified slurry of hydrophobic and oleophobic powder is shown in Table 6 in this example.

[0098] The formula composition of the pre-emulsified slurry of the hydrophobic and oleophobic powder of table 6

[0099]

[0100]

[0101] Preparation Process:

[0102] 1. Weigh the raw materials of phase A in a beaker in turn, heat at 80°C until the raw materials are completely melted, then stop heating and stir evenly;

[0103] 2. Add phase B raw materials into phase A, stir (380-400 rpm) for 8-10 minutes, then homogenize (10000-20000 rpm) for 5 minutes to disperse the powder evenly;

[0104] 3. Under rapid stirring (400-500 rpm), slowly add phase C to phase AB to make the emulsification complete. High-speed homogenization (10000 rpm) until the material body is uniform and fine;

[0105] 4. Use a three-roll machine to grind 3 to 4 times to get "2# pre-emulsified slurry of hydrophobic and oleophobic powder".

Embodiment 3

[0107] The formula (by weight) of the pre-emulsified slurry of hydrophobic and oleophobic powder is shown in Table 7 in this example.

[0108] The formula composition of the pre-emulsified slurry of the hydrophobic and oleophobic powder of table 7

[0109]

[0110]

[0111] Preparation Process:

[0112] 1. Weigh the raw materials of phase A in a beaker in turn, heat at 80°C until the raw materials are completely melted, then stop heating and stir evenly;

[0113] 2. Add phase B raw materials into phase A, stir (380-400 rpm) for 8-10 minutes, then homogenize (10000-20000 rpm) for 5 minutes to disperse the powder evenly;

[0114] 3. Under rapid stirring (400-500 rpm), slowly add phase C to phase AB to make the emulsification complete. High-speed homogenization (10000 rpm) until the material body is uniform and fine;

[0115] 4. Use a three-roll machine to grind 3 to 4 times to get "3# pre-emulsified slurry of hydrophobic and oleophobic powder".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com