Pre-emulsified slurry of hydrophobic and oleophobic powder, preparation method and application thereof

A hydrophobic and oleophobic, pre-emulsification technology, used in cosmetic preparations, cosmetics, cosmetics, etc., can solve the problems of large equipment loss, difficult to disperse uniformly, and unstable dispersion slurry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

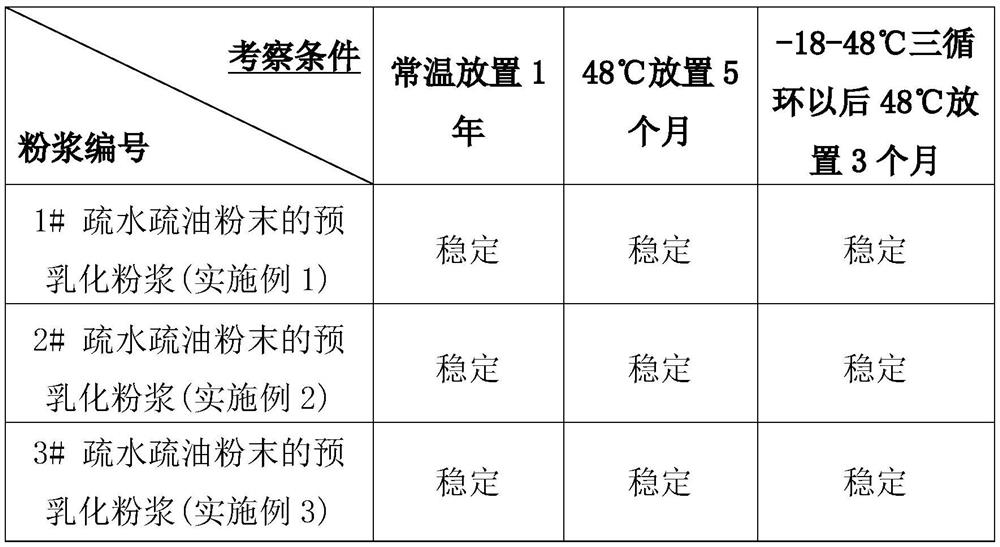

Embodiment 1

[0087] The formula (by weight) of the pre-emulsified slurry of the hydrophobic and oleophobic powder in this example is shown in Table 5.

[0088] The formula composition of the pre-emulsified slurry of the hydrophobic and oleophobic powder of table 5

[0089]

[0090]

[0091] Preparation Process:

[0092] 1. Weigh the raw materials of phase A in a beaker in turn, heat at 80°C until the raw materials are completely melted, then stop heating and stir evenly;

[0093] 2. Add the raw materials of phase B to phase A in turn, stir (380-400 rpm) for 8-10 minutes, and then homogenize (10000-20000 rpm) for 5 minutes to disperse the powder evenly;

[0094] 3. Under rapid stirring (400-500 rpm), slowly add phase C to phase AB to make the emulsification complete. High-speed homogenization (10000 rpm) until the material body is uniform and fine;

[0095] 4. Use a three-roll machine to grind 3 to 4 times to get "1# pre-emulsified slurry of hydrophobic and oleophobic powder".

Embodiment 2

[0097] The formula (by weight) of the pre-emulsified slurry of hydrophobic and oleophobic powder is shown in Table 6 in this example.

[0098] The formula composition of the pre-emulsified slurry of the hydrophobic and oleophobic powder of table 6

[0099]

[0100]

[0101] Preparation Process:

[0102] 1. Weigh the raw materials of phase A in a beaker in turn, heat at 80°C until the raw materials are completely melted, then stop heating and stir evenly;

[0103] 2. Add phase B raw materials into phase A, stir (380-400 rpm) for 8-10 minutes, and then homogenize (10000-20000 rpm) for 5 minutes to disperse the powder evenly;

[0104] 3. Under rapid stirring (400-500 rpm), slowly add phase C to phase AB to make the emulsification complete. High-speed homogenization (10000 rpm) until the material body is uniform and fine;

[0105] 4. Use a three-roll machine to grind 3 to 4 times to get "2# pre-emulsified slurry of hydrophobic and oleophobic powder".

Embodiment 3

[0107] The formula (by weight) of the pre-emulsified slurry of hydrophobic and oleophobic powder is shown in Table 7 in this example.

[0108] The formula composition of the pre-emulsified slurry of the hydrophobic and oleophobic powder of table 7

[0109]

[0110]

[0111] Preparation Process:

[0112] 1. Weigh the raw materials of phase A in a beaker in turn, heat at 80°C until the raw materials are completely melted, then stop heating and stir evenly;

[0113] 2. Add phase B raw materials into phase A, stir (380-400 rpm) for 8-10 minutes, and then homogenize (10000-20000 rpm) for 5 minutes to disperse the powder evenly;

[0114] 3. Under rapid stirring (400-500 rpm), slowly add phase C to phase AB to make the emulsification complete. High-speed homogenization (10000 rpm) until the material body is uniform and fine;

[0115] 4. Use a three-roll machine to grind 3 to 4 times to get "3# pre-emulsified slurry of hydrophobic and oleophobic powder".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com