Numerical control both-position carving machine

An engraving machine and two-position technology, applied in the field of plane engraving, can solve the problems of complex equipment structure, complex control program, low engraving efficiency, etc., and achieve the effects of simplified process, accurate positioning and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

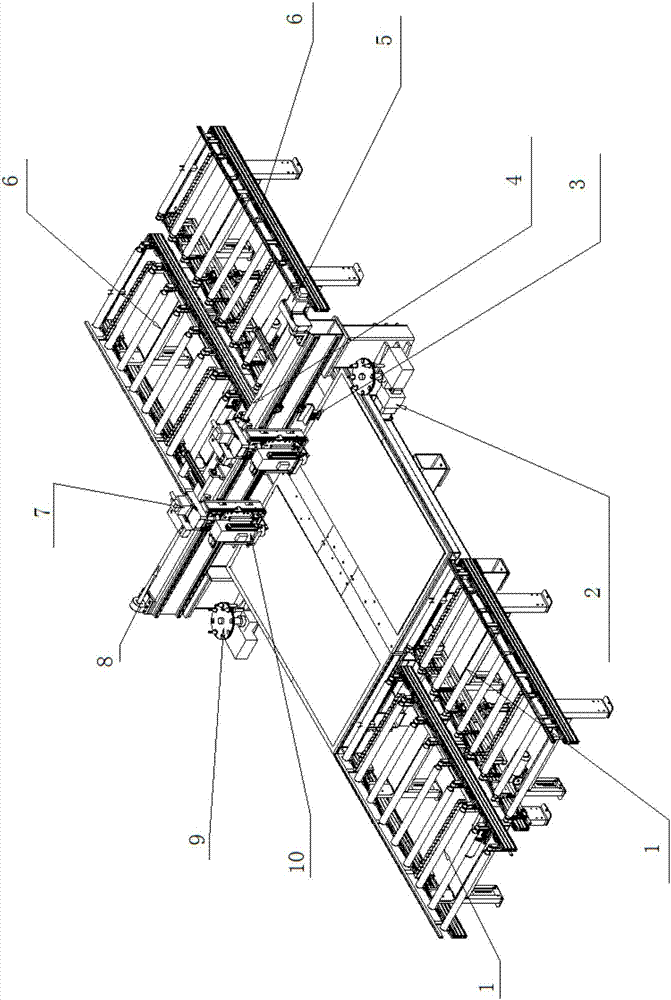

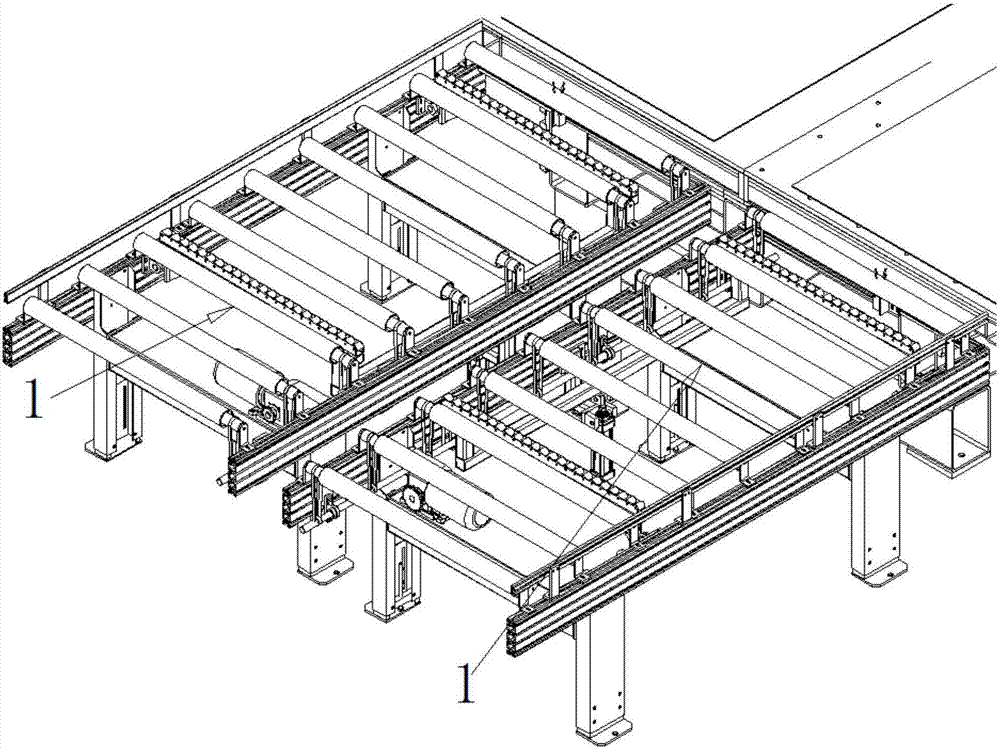

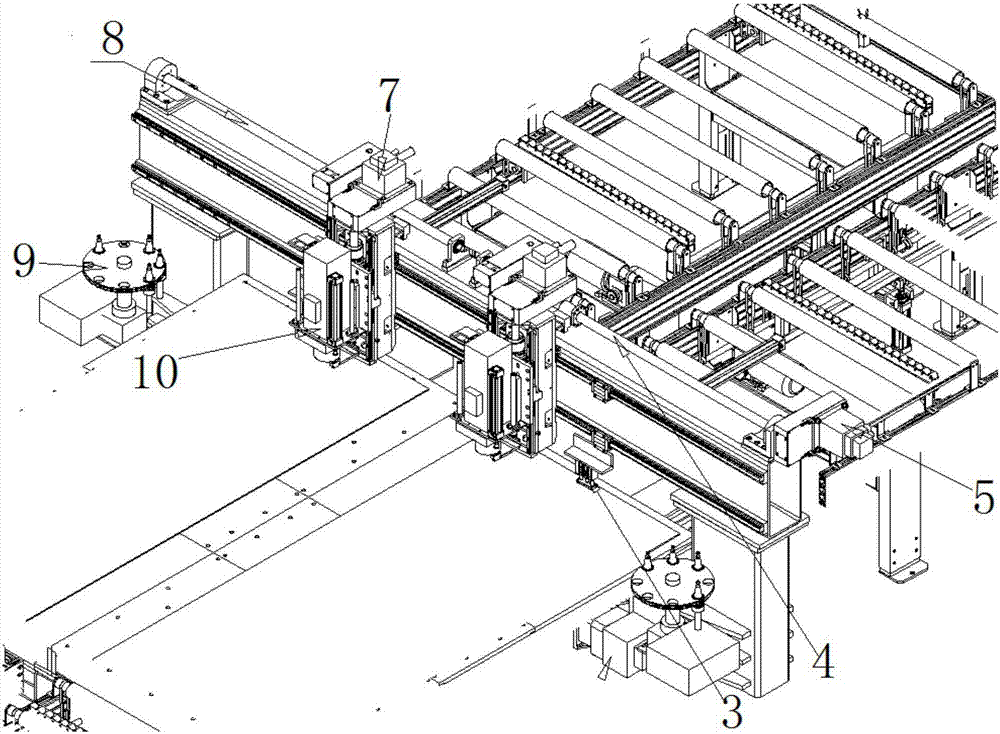

[0024] CNC double-position engraving machine, see Figure 1-3 , the direction of workpiece feeding is the X direction, the direction perpendicular to the X direction is the Y direction, and the direction perpendicular to the XOY plane is the Z direction, including the Y-axis forward screw rod 4 and the Y-axis reverse screw rod 8. The Y-axis positive rotation screw 4 and the Y-axis reverse rotation screw 8 are connected together to form a two-way screw; the plane engraving product is divided into A surface part and B surface part, and the A surface part and B surface part are centered on the X direction The line is symmetrically arranged; the two spindle power sources are respectively fixed on the Y-axis forward-rotating screw rod 4 and the Y-axis reverse-rotating screw rod 8, and are arranged symmetrically with the center line; the control unit controls the X, Y, Z-axis power sources and The spindle power sources work together to engrave the A-side and B-side parts of the work...

Embodiment 2

[0033] The difference from the first embodiment is that the working platform has a mechanical positioning device for positioning the wooden door to be carved.

[0034] The invention realizes the double-sided engraving of the workpiece at one time, and the working efficiency of the engraving machine is greatly improved; the mirror image engraving is realized by using the two-way screw rod, the front and back sides of the workpiece are accurately positioned, and the reliability is high; there is no need to flip the workpiece, the equipment is simplified, and the process is simplified; no complicated Advanced control program, less investment in equipment, low failure rate.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap