Clothes airing machine positioning winding device

A technology for a winding device and a clothes drying machine, which is applied to a hoisting device, a washing device, and other drying devices, etc., can solve the problems of large axial size, complex structure, and the inability of two winding reels to act synchronously, and achieves The effect of large axial size, good synchronization and few parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings of the description.

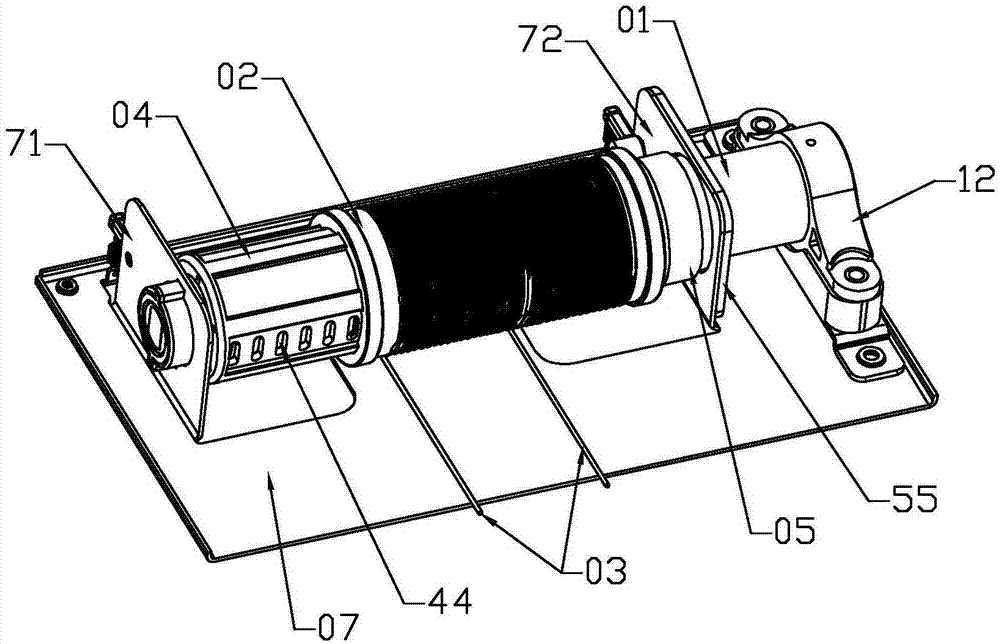

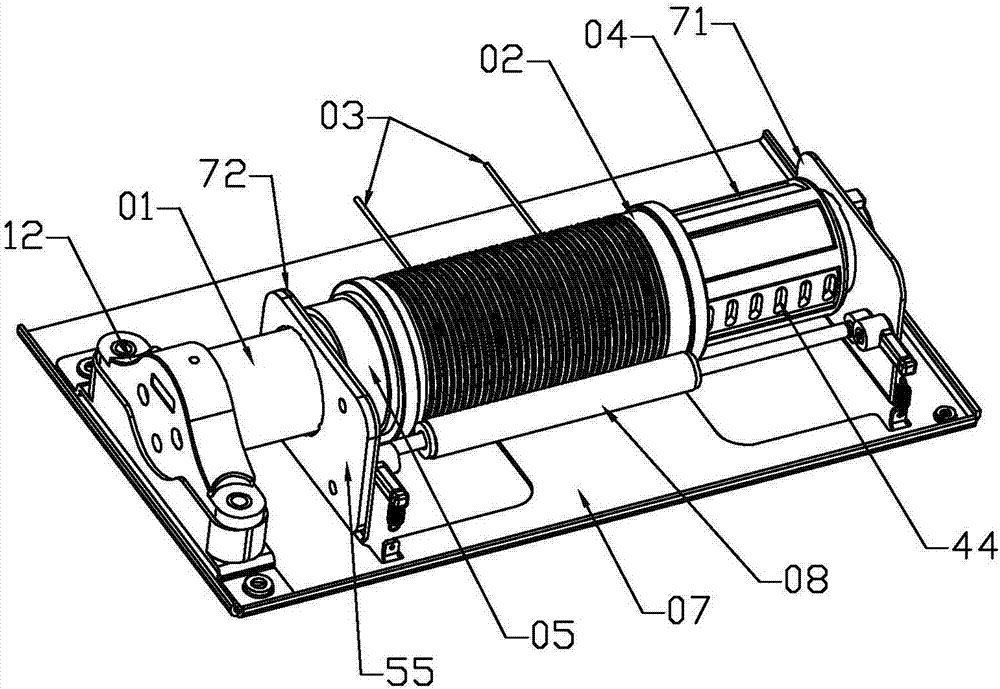

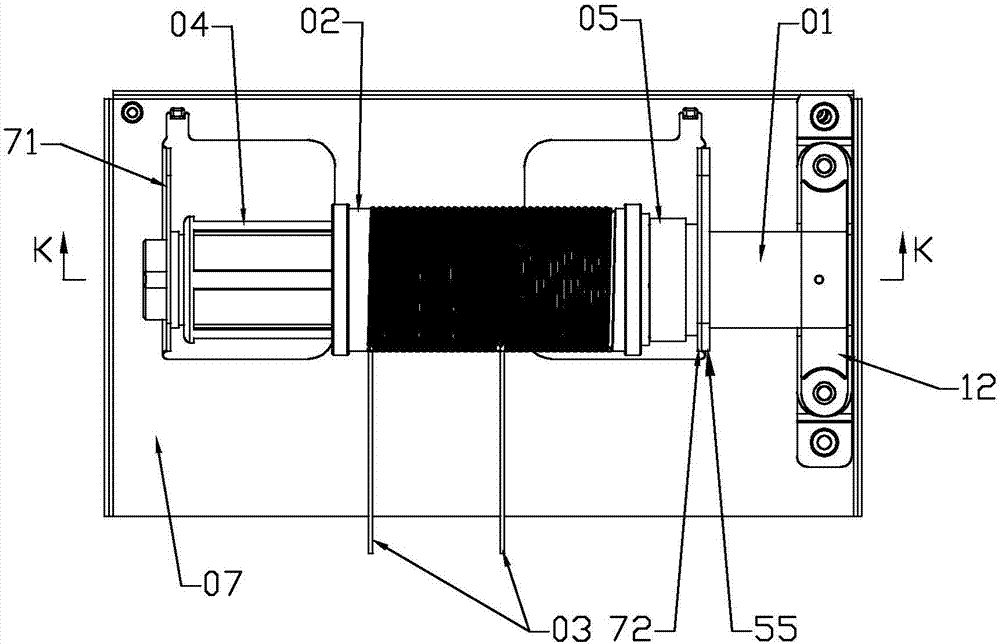

[0039] Such as Figure 1-4 As shown, it is a preferred embodiment of the positioning and winding device of the clothes dryer of the present invention, and the positioning and winding device of the clothes drying machine includes:

[0040] Fixed tubular motor 01 with a rotating output shaft 11 at one end (see Figure 4-5 );

[0041] The cylindrical reel 02 is set outside the tubular motor 01, its outer wall is provided with a spiral winding groove 21, and its inner wall includes an internal thread section 22 and a power transmission section 23 (see Figure 7 ), the direction of rotation of the internal thread segment 22 is the same as that of the helical winding groove 21, and the pitch of the internal thread segment 22 is equal to the pitch of the helical winding groove 21;

[0042] Two steel wire ropes 03 are respectively wound in different posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com