Exhaust gas after-treatment arrangement and method for operating such an arrangement

A technology for exhaust post-treatment and exhaust pipes, which is applied in exhaust treatment, exhaust devices, machines/engines, etc. It can solve problems such as high back pressure, high fuel consumption, and the size of the catalytic converter cannot be designed to achieve good reliability. The effect of control and adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

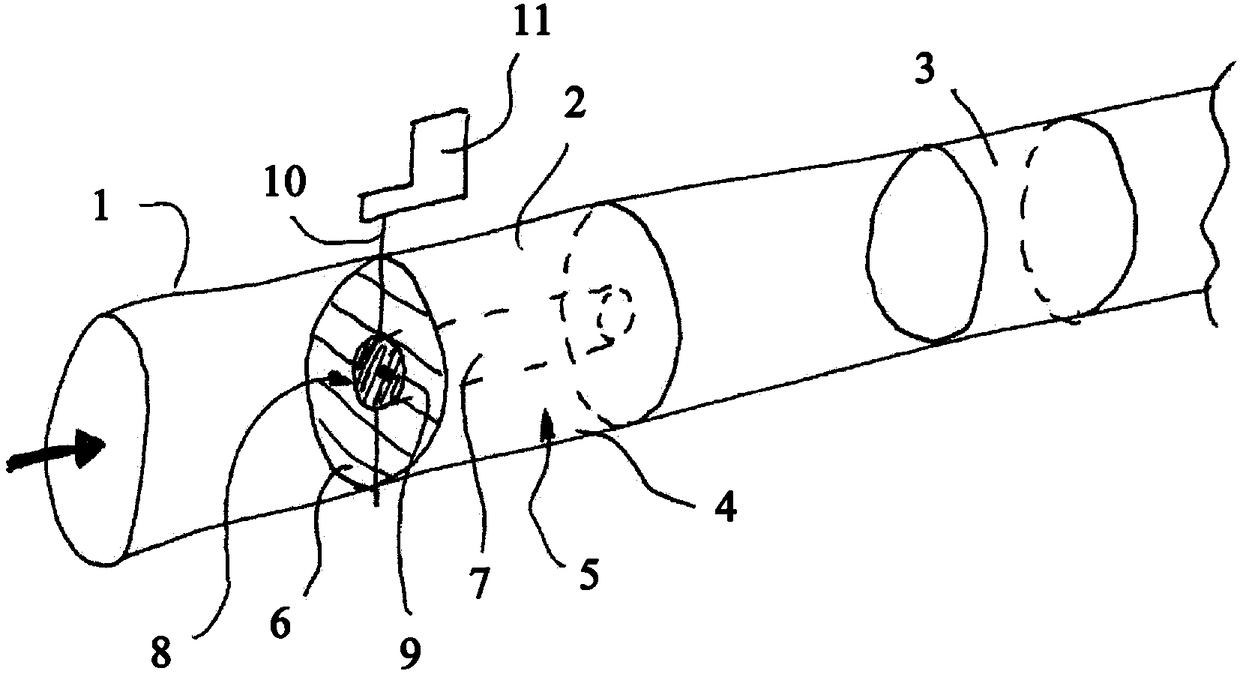

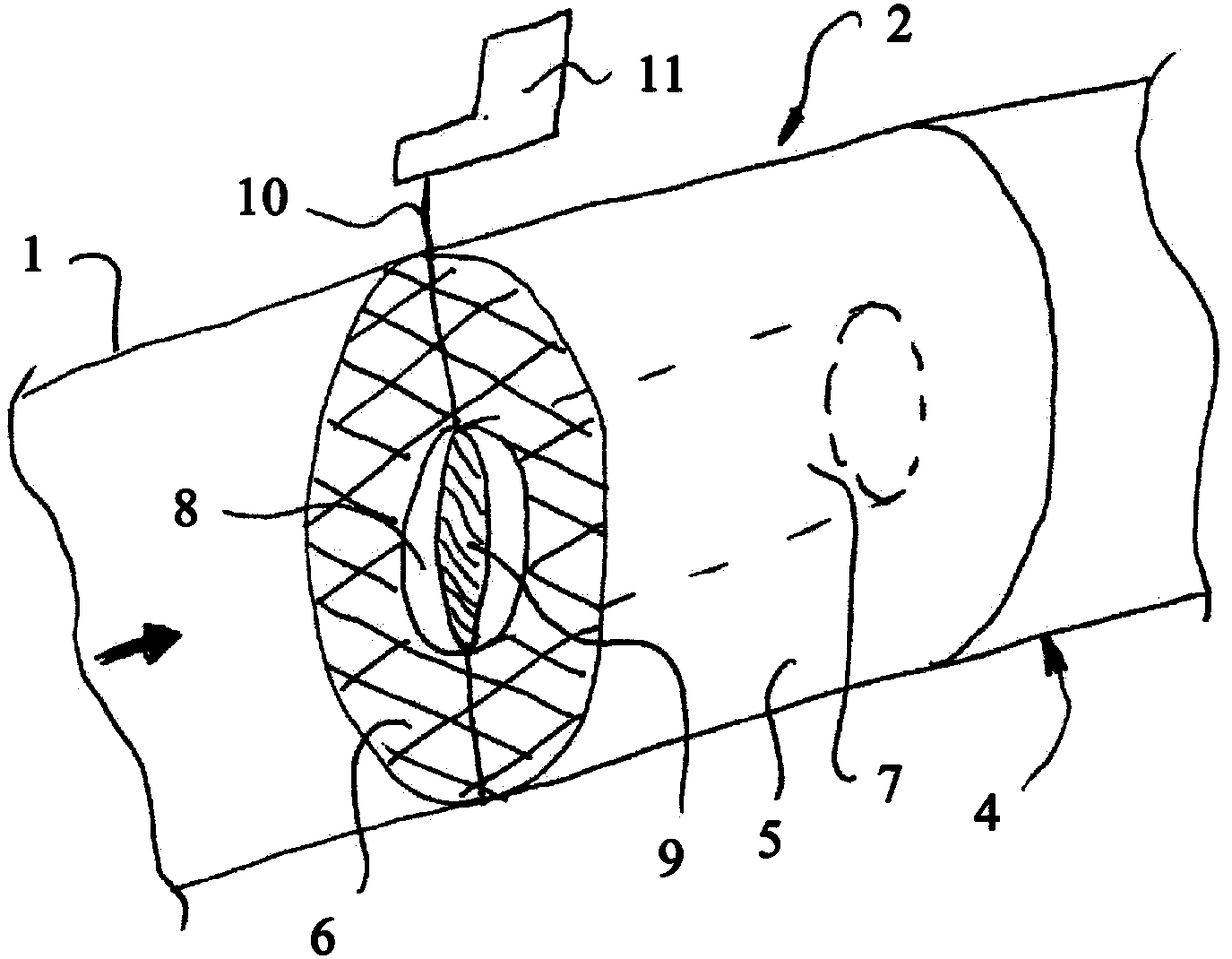

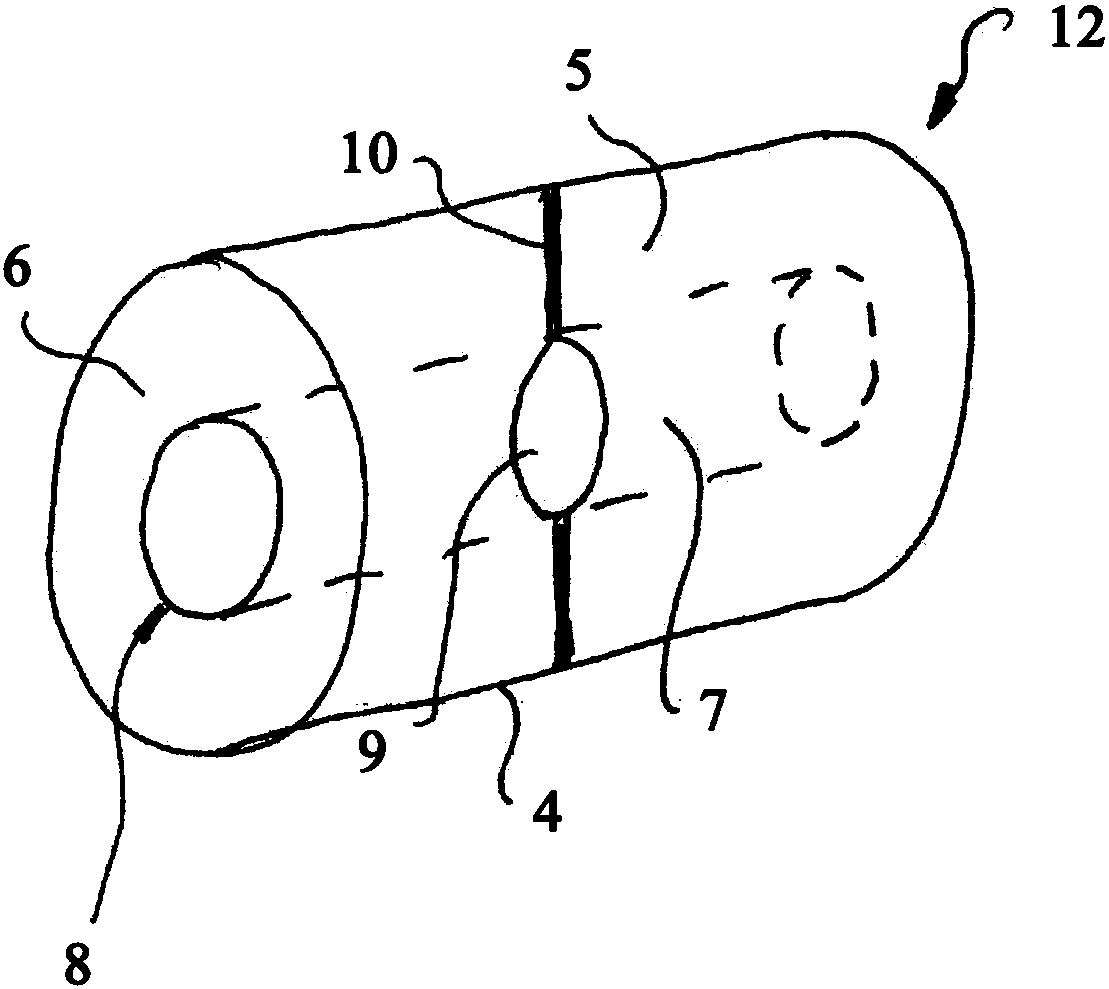

[0032] figure 1A section of an exhaust gas line 1 is shown, in which a catalytic converter is arranged as an exhaust gas aftertreatment device 2 . A further exhaust-gas aftertreatment device 3 , which is also designed as a catalytic converter, is arranged downstream of the catalytic converter 2 . The catalytic converter 2 has a housing 4 which surrounds a honeycomb body 5 . The honeycomb body 5 is formed from a plurality of laminates which form the catalytic converter body 6 and are overflow surfaces for the exhaust gas, wherein catalytic reactions take place in the flowing exhaust gas when flowing through the catalytic converter body 6 . Along its longitudinal axis, the honeycomb body 5 has a central cell 7 through which the exhaust gas can flow while avoiding the catalytic converter base body 6 . The main flow direction of the exhaust gas is indicated by arrows. A movable element 9 is provided on the inlet 8 of the duct 7 , which blocks the inlet 8 in the illustration sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com