Silicon-on-insulator lateral n-type insulated gate bipolar transistor

A bipolar transistor, silicon-on-insulator technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of increasing channel length, changing to P-type, and reducing gate turn-off performance, so as to reduce conduction The effect of increasing the resistance, increasing the lateral withstand voltage, and increasing the conduction current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

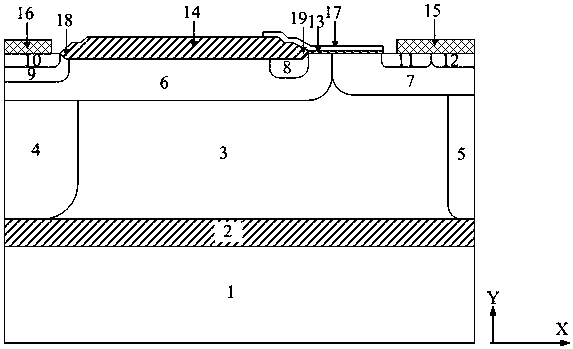

[0014] refer to figure 1 , a silicon-on-insulator lateral N-type insulated gate bipolar transistor, comprising: a P-type doped semiconductor substrate 1, a buried oxide layer 2 is arranged on the P-type doped semiconductor substrate 1, and a buried oxide layer 2 is arranged on the buried A P-type doped epitaxial layer 3 is arranged on the oxygen layer 2, an N-type doped deep well region 4 is arranged on the left side of the P-type doped epitaxial layer 3, and an N-type doped deep well region 4 is arranged on the right side of the P-type doped epitaxial layer 3. A P-type doped deep well region 5 is provided on the side, an N-type doped drift region 6 is arranged above the N-type doped deep well region 4 and part of the P-type doped epitaxial layer 3, and an N-type doped drift region 6 is arranged on the P-type doped deep well region 4 and part of the P-type doped epitaxial layer 3. A P-type doped semiconductor region 7 is arranged above the P-type doped deep well region 5 and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com