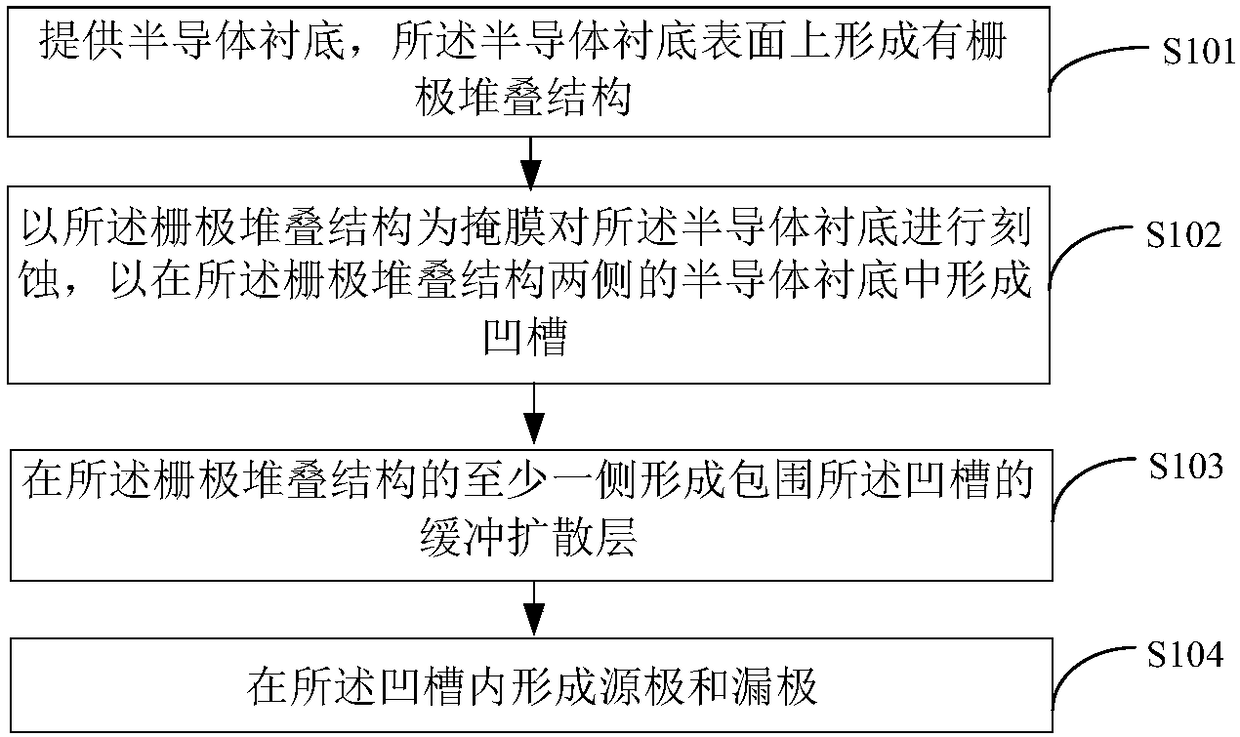

Manufacturing method of semiconductor device

A manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of increased junction leakage current and performance degradation of semiconductor devices, so as to reduce junction capacitance and junction leakage current and improve good performance. rate and performance, avoiding the effects of lateral diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

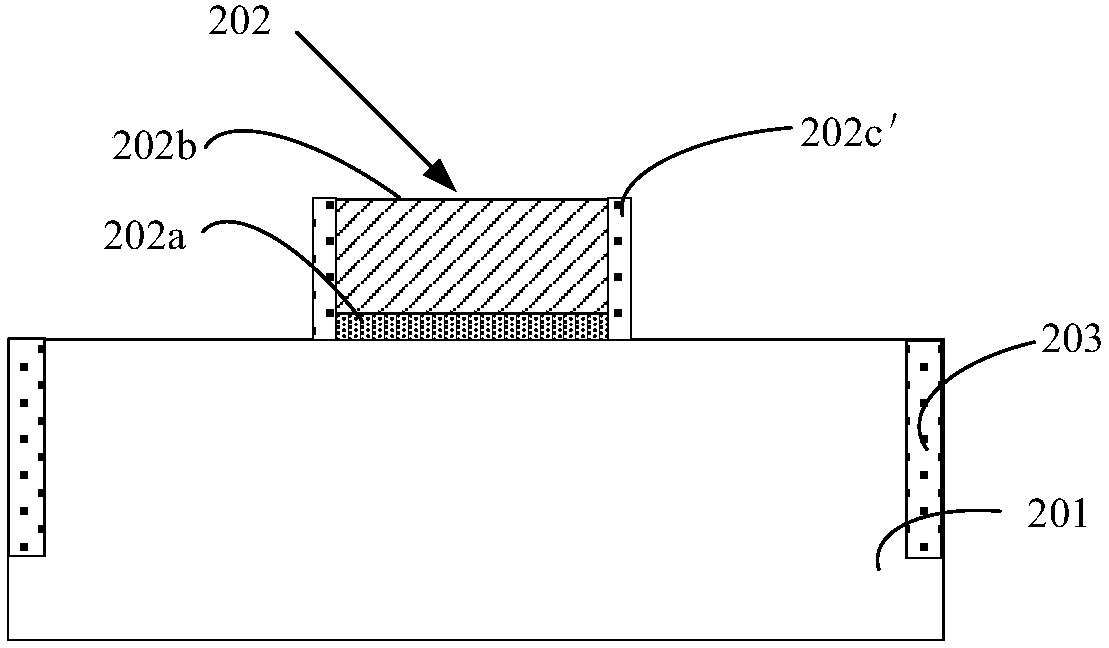

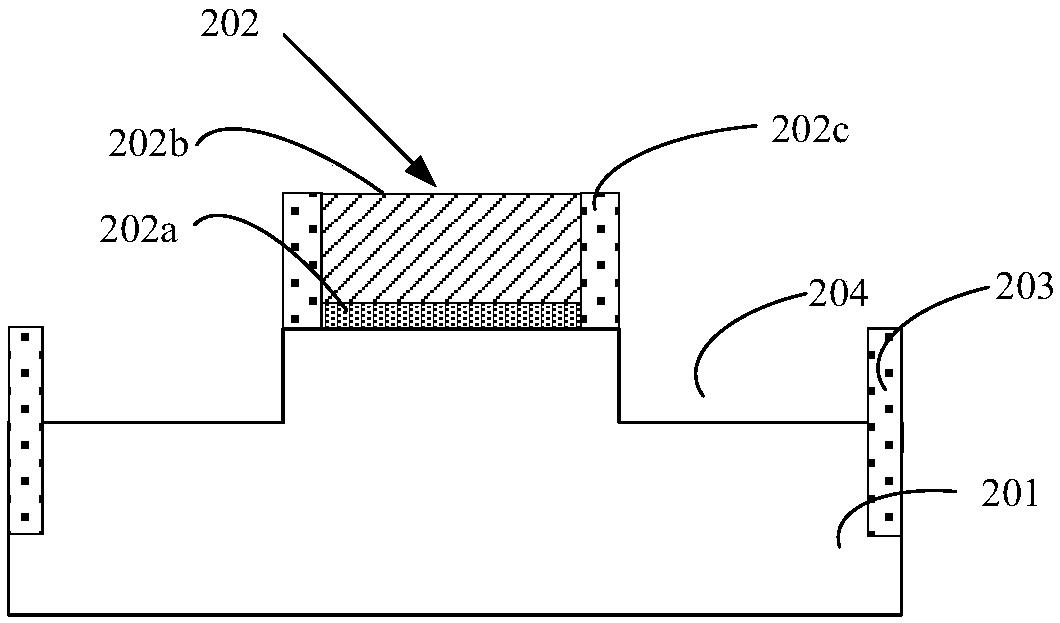

[0039] Take P-type Metal-Oxide-Semiconductor Field-Effect Transistor (Metal-Oxide-Semiconductor Field-Effect Transistor, MOSFET) as an example, refer to Figure 2A-Figure 2E , which shows schematic cross-sectional views of semiconductor devices respectively obtained by sequentially implementing steps according to the method of Embodiment 1 of the present invention.

[0040] First, if Figure 2A As shown, a semiconductor substrate 201 is provided, and a gate stack structure 202 is formed on the surface of the semiconductor substrate 201, and then a lightly doped process (Lightly Doped Drain, LDD) is used to inject The region of the gate stack structure 202 is ion implanted and annealed to form a lightly doped drain (LDD) ion implantation region (not shown in the figure) in the region of the semiconductor substrate 201 adjacent to the gate stack structure 202 .

[0041]Further, the constituent material of the semiconductor substrate 201 can be undoped single crystal silicon, si...

Embodiment 2

[0061] Taking P-type metal-oxide semiconductor field-effect transistor (Metal-Oxide-Semiconductor Field-Effect Transistor, MOSFET) as an example, refer to Figure 3A-Figure 3F , which shows schematic cross-sectional views of semiconductor devices respectively obtained by sequentially implementing steps according to the method of Embodiment 2 of the present invention.

[0062] First, if Figure 3A As shown, a semiconductor substrate 301 is provided, and a gate stack structure 302 is formed on the surface of the semiconductor substrate 301, and then a lightly doped process (Lightly Doped Drain, LDD) is used to lightly doped the semiconductor substrate 301 adjacent to the gate The region of the gate stack structure 302 is ion implanted and annealed to form a lightly doped drain (LDD) ion implantation region (not shown in the figure) in the region of the semiconductor substrate 301 adjacent to the gate stack structure 302 .

[0063] Further, the constituent material of the semico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com