Formation method of transistor

A technology of transistors and semiconductors, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as transistor performance needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

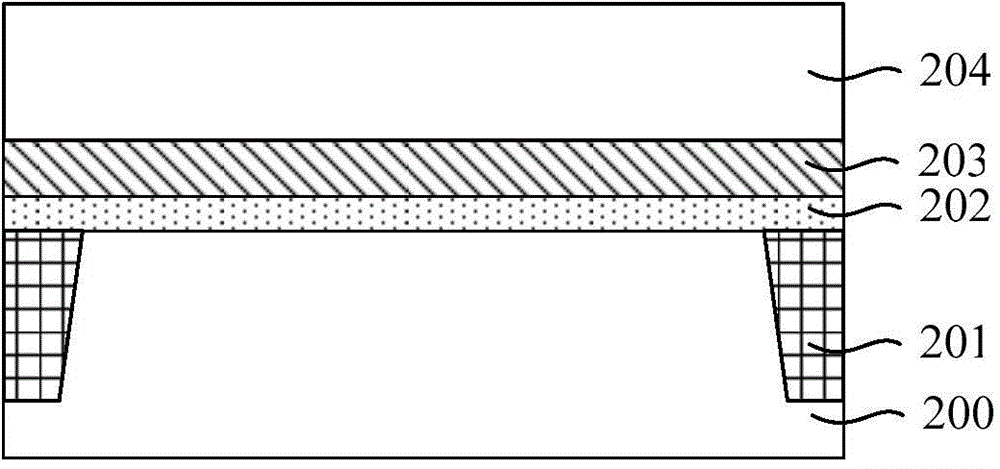

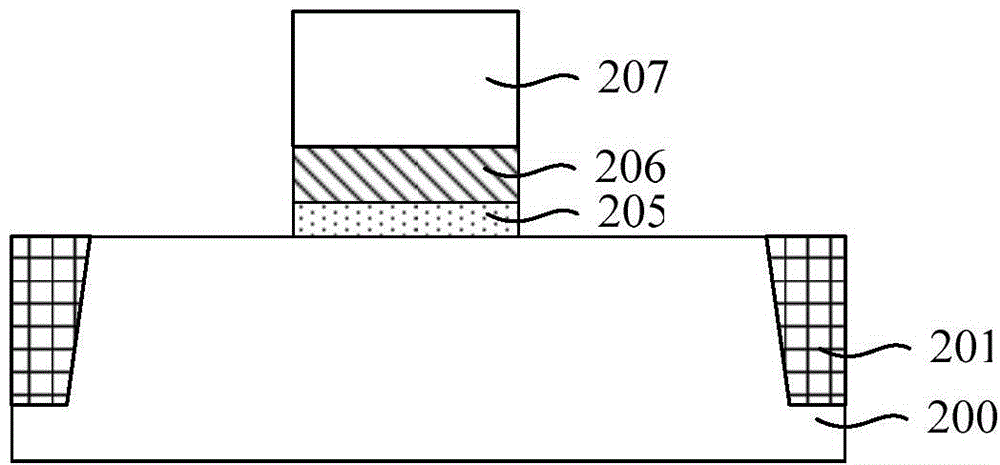

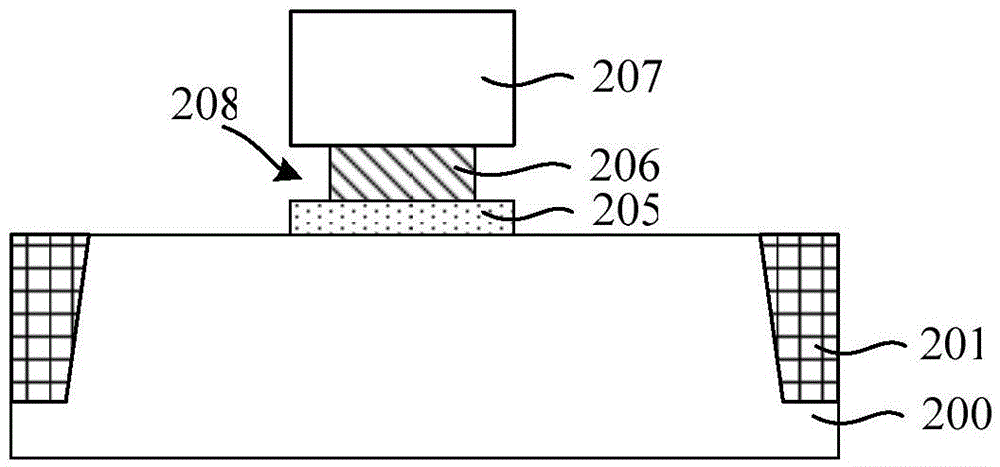

[0034] The performance of the conventionally formed transistors still needs to be improved, for example, the problem of the short channel effect still exists in the transistors formed by the prior art.

[0035] Research has found that in the prior art, there are problems of uneven ion concentration distribution and inaccurate position in the pocket implant region formed by ion implantation in the pocket implant region, especially in the parts near the bottom of the gate electrode and the channel region of the transistor. It is outstanding that the transistor still has the problem of short channel when it is working. Further studies have found that the reason for the uneven distribution of ion concentration and inaccurate positions in the pocket implantation region is that during the pocket ion implantation process, the gate electrode and offset sidewalls will affect the implanted ion beam.

[0036]To this end, the present invention provides a method for forming a transistor. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com